Adjustable Combustion Atmosphere Burner and Experimental Method

A burner and atmosphere technology, applied in combustion methods, combustion chambers, combustion equipment, etc., to achieve the effects of convenient operation, simple structure design, and reliable sample introduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

Specific embodiment 1:

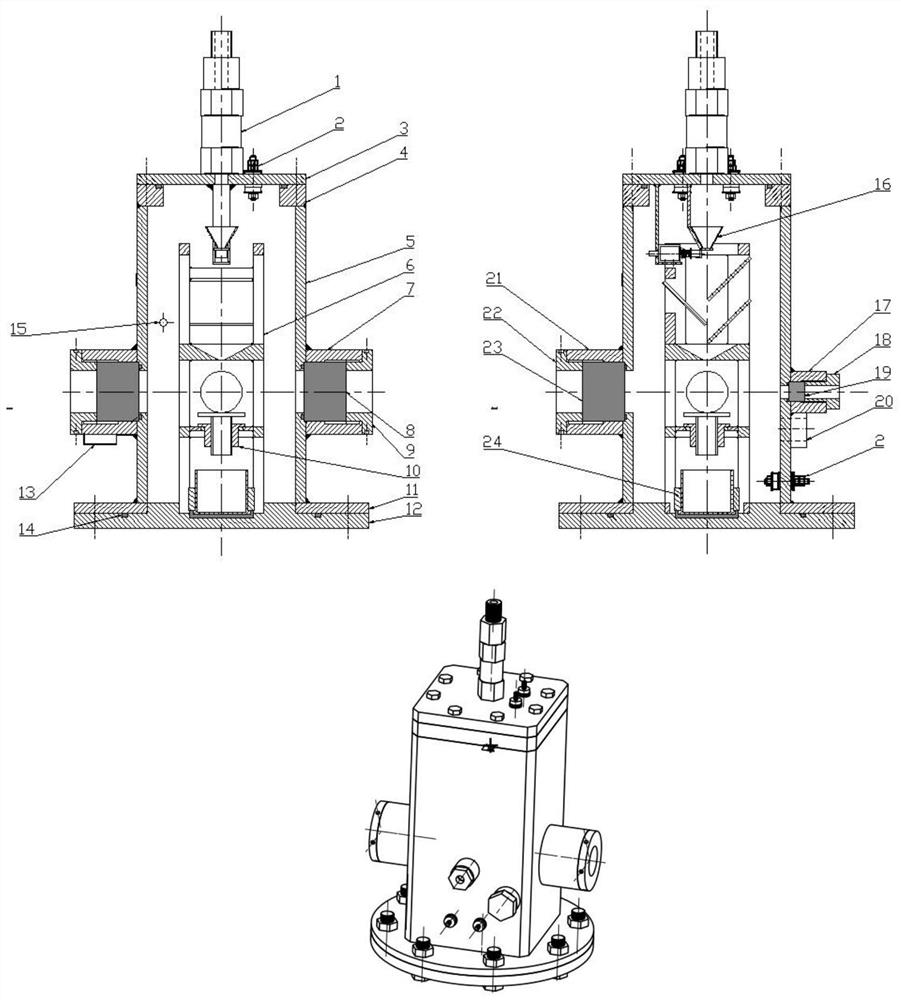

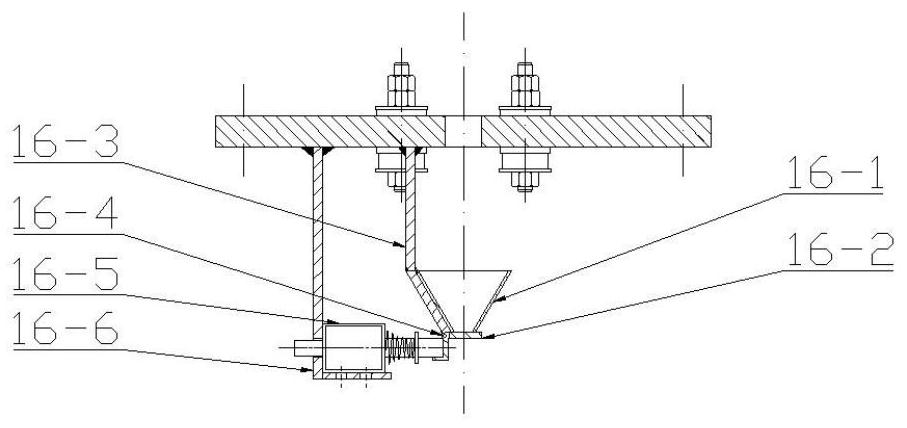

[0056]Step 1. Install the O-ring 14 between the main body of the combustion chamber and the bottom plate 12 of the combustion chamber and fasten it with bolts. Fill the corresponding O-rings in the laser incident window 17, the quartz glass observation window 7 and the laser stopper window 21 respectively. Press the quartz glass 8, the germanium glass 19, and the laser block 23 into the corresponding windows respectively, and screw into the corresponding pressing screws, and tighten them with a hook wrench. The sealing electrode 2 is respectively loaded into the burner side wall 5 and the burner top plate 3, and the electromagnet 16-5 of the powder fuel sampling mechanism 3 is connected to the sealing electrode 2 of the burner top plate 3, and the top surface of the burner top plate The female thread of the check valve is externally connected to the male thread, and tightened with a wrench.

[0057] Screw the four-way interface into the burner air inle...

specific Embodiment 2

[0058] Step 2. Close the exhaust valve of the burner, open the pressure signal acquisition system, collect the pressure data of the combustion chamber cavity, open the intake valve connected to the high-pressure nitrogen source, and inject nitrogen into the combustion chamber in stages to make the internal pressure of the burner reach 1MPa in sequence , 2MPa, 3MPa, and 4MPa, close the pressure reducing valve and intake valve, and keep it for 5 minutes. If the pressure in the combustion chamber does not change, make sure that the airtightness of the combustion chamber is good, open the exhaust valve to discharge the gas in the combustion chamber, and loosen the combustion chamber with a wrench. screw on the top plate 3 on the device, and remove it.

Specific embodiment 2:

[0060] Step 1. Install the O-ring 14 between the main body of the combustion chamber and the bottom plate 12 of the combustion chamber and fasten it with bolts. Fill the corresponding O-rings in the laser in...

specific Embodiment 3

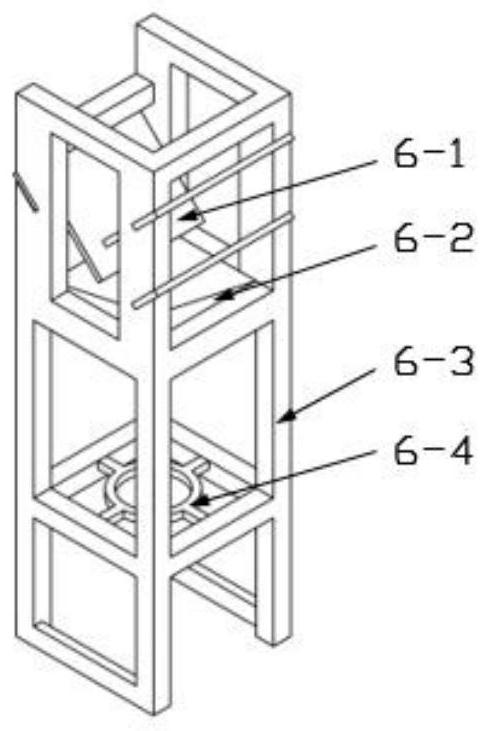

[0064] Step 4. Turn on the pressure acquisition system, use high-pressure nitrogen source and high-pressure oxygen source to feed 1MPa nitrogen and 0.5MPa oxygen into the burner, and then wait for five minutes to observe the pressure in the burner through the pressure acquisition system. Good air tightness. Trigger the stabilized power supply, the electromagnet 16-5 in the powder fuel sampling mechanism 16 shrinks, the rotating baffle 16-2 rotates, the boron particles land, and then the laser igniter is turned on, and the spectrometer and high-speed camera are triggered at the same time. The boron particles are ignited by contacting the laser beam after passing through the powder dispersion device 6 . At this time, the spectrometer collected the combustion spectrum of boron particles, and the high-speed camera captured the flame structure of boron particles.

[0065] Step 5. Turn off the stabilized power supply, stop the laser generator, high-speed camera and spectrometer, op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com