PH value sensitive micro capsule as well as preparation method and application thereof

A kind of microcapsule and sensitive technology, applied in the directions of microcapsule preparation, microsphere preparation, etc., can solve the problem that the effect of indicating discoloration is difficult to maintain, and achieve the effect of rich pores, favorable for firm connection and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

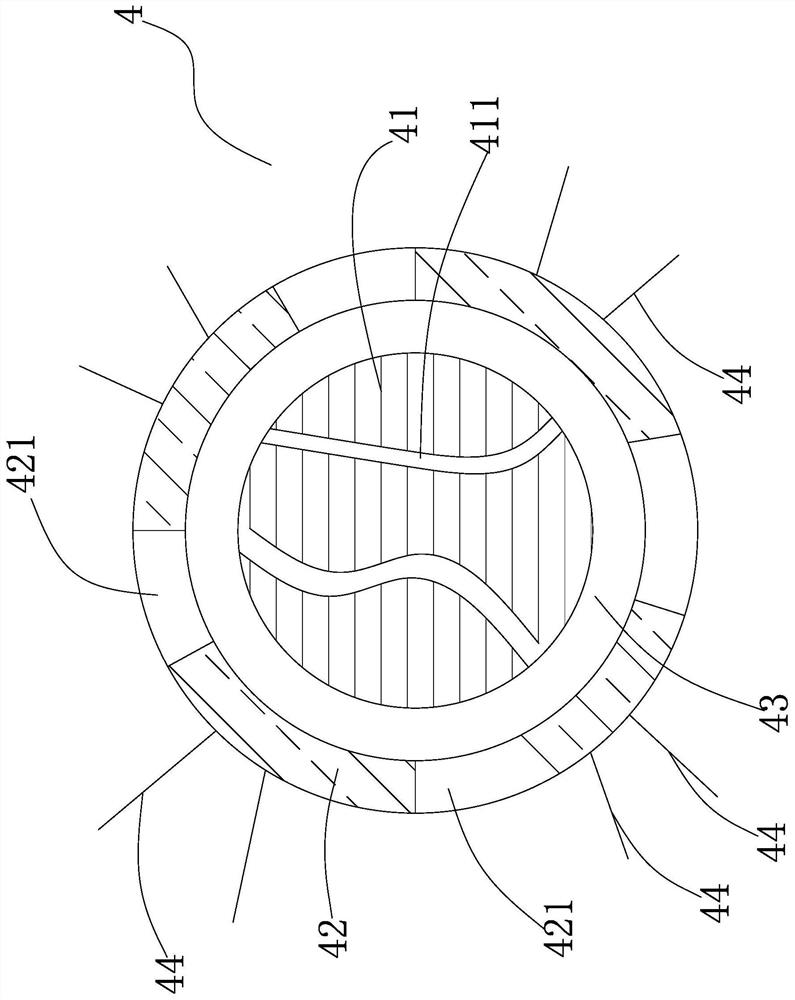

Image

Examples

Embodiment 1

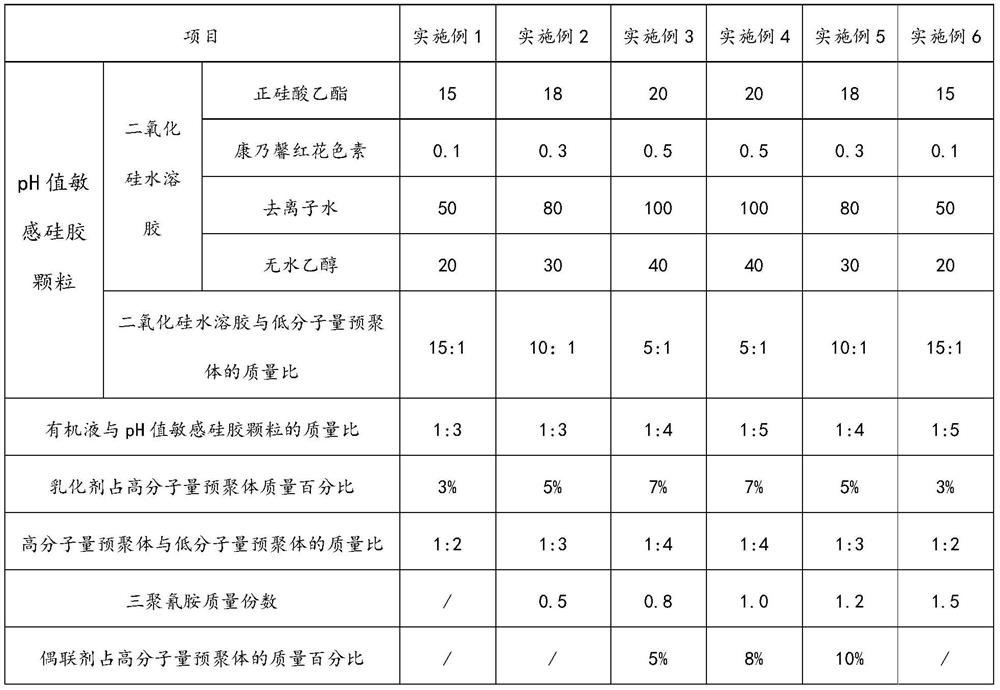

[0041] This embodiment discloses a preparation method of pH-sensitive microcapsules,

[0042] Include the following steps:

[0043] Step 1, mixing the pH-sensitive silica gel with primary pores coated with vegetable oil or glycerin layer with an emulsifier aqueous solution;

[0044] The emulsifier is sodium lauryl sulfate, and the mass of the emulsifier is 3% to 7% of the mass of the high molecular weight water-soluble prepolymer solution.

[0045] The preparation method of the pH sensitive silica gel comprises the following steps:

[0046] S1, preparation of silica hydrosol

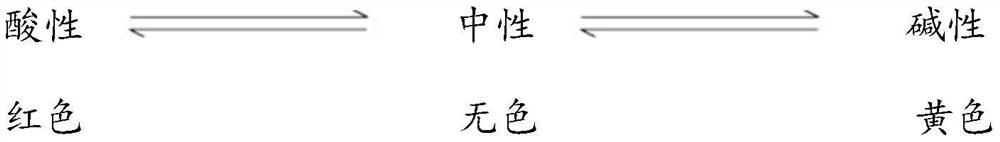

[0047] Stir and mix ethyl orthosilicate, carnation safflower pigment, absolute ethanol and deionized water to obtain a yellow silica hydrosol;

[0048] S2, adjusting the pH value of the yellow silica hydrosol to 2;

[0049] S3, continuously add low molecular weight water-soluble prepolymer to the mixed solution of S2 under stirring condition, and react to obtain precipitation;

[0050] S4. The precipi...

Embodiment 2

[0068] The main difference between this embodiment and Example 1 is shown in Table 1. The pH value sensitive microcapsules prepared in this embodiment are made of textiles by the same method as in Example 1. The specific performance test is the same as in Example 1. The specific test The results are shown in Table 2 and Table 3 in detail.

Embodiment 3

[0070] The main difference between this embodiment and Example 1 is shown in Table 1. The pH value sensitive microcapsules prepared in this embodiment are made of textiles by the same method as in Example 1. The specific performance test is the same as in Example 1. The specific test The results are shown in Table 2 and Table 3 in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com