Tantalum alloy, preparation method of tantalum alloy seamless tube and tantalum alloy seamless tube

A technology of tantalum alloy and seamless tube, which is applied in the fields of tantalum alloy seamless tube and its preparation, tantalum alloy and its preparation, and can solve problems such as insufficient equipment strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050]Further, a method for preparing a tantalum alloy is also provided, including the following steps:

[0051]Vacuum sintering to obtain a metal sintered bar;

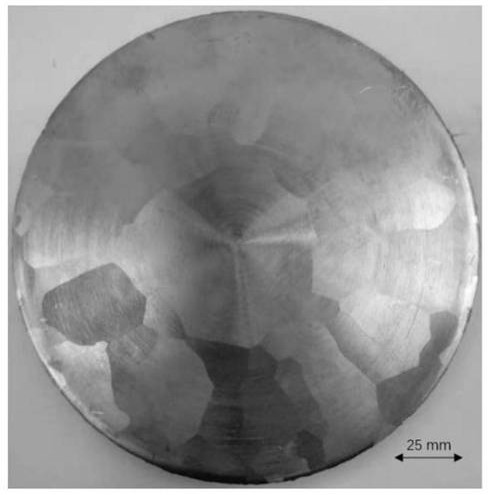

[0052]Perform two electron beam smelting on the metal sintered bar to obtain a metal alloy ingot;

[0053]Thermal mechanical processing is performed on the metal alloy ingot to obtain a tantalum alloy billet.

[0054]Furthermore, a method for preparing a tantalum alloy seamless pipe is also provided, which includes the following steps:

[0055]The tantalum alloy billet prepared by the above-mentioned tantalum alloy preparation method is used as the raw material, and the raw material is forged and billeted by a screw press after the temperature is kept at 980-1200°C for 30 minutes. Cumulative deformation rate ≥40%, to obtain the first tantalum alloy;

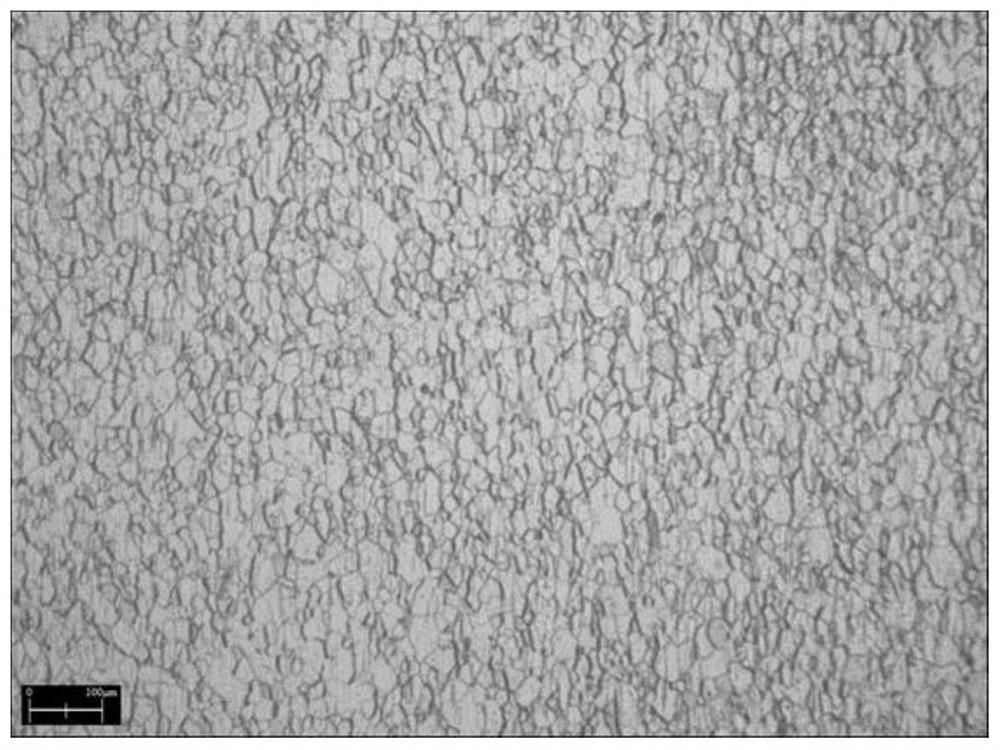

[0056]Performing vacuum recrystallization annealing on the first tantalum alloy by a vacuum annealing furnace, and cooling the first tantalum alloy after the vacuum recrystallization annealing...

Embodiment 1

[0079]The Ta-4Mo-4Re tantalum alloy specifically follows the following steps:

[0080]Weigh 5kg of molybdenum powder, 3.5kg of rhenium powder and 91.5kg of tantalum powder, put the metallurgical raw materials into a mixer and mix them, put the mixed metallurgical raw materials into a plastic sleeve every 10kg, and place them in an isostatic press In the middle, the metal strips are pressed into a total of 10, and the above 10 metal bars are respectively placed in a vertical melting furnace for vacuum vertical melting and sintering. The vacuum degree of the vertical melting furnace is 3.5x10-3Pa, vacuum vertical melting and sintering lasts for 3h until the temperature of the metal strip reaches 1700℃, then the temperature of the metal strip is raised to 2200℃ in increments of 100℃, the metal strip is kept at 2200℃ for 4 hours, and then cooled in vacuum After 5 hours to room temperature, 10 vacuum sintered alloy bars totaling 100 kg were obtained.

[0081]After that, the 10 vacuum sintered ...

Embodiment 2

[0087]The Ta-4Mo-4Re tantalum alloy specifically follows the following steps:

[0088]Weigh 5kg of molybdenum powder, 4.3kg of rhenium powder and 90.7kg of tantalum powder, put the metallurgical raw materials in a mixer and mix them, put the mixed metallurgical raw materials into a plastic sleeve every 10kg, and place them in an isostatic press In the middle, the metal bars are pressed into a total of 10; the above 10 metal bars are respectively placed in a vertical melting furnace for vacuum vertical melting and sintering, and the vacuum degree of the vertical melting furnace is 3.5x10-3Pa, vacuum vertical melting and sintering lasts for 3h until the temperature of the metal strip reaches 1700℃, then the temperature of the metal strip is raised to 2200℃ in increments of 100℃, the metal strip is kept at 2200℃ for 4 hours, and then cooled in vacuum After 5 hours to room temperature, 10 vacuum sintered alloy bars totaling 100 kg were obtained.

[0089]After that, the 10 vacuum sintered allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com