Preparation method and application of phosphorus-doped carbon nitride two-dimensional nanoparticles for preparing flame-retardant waterborne polyurethane

A water-based polyurethane and two-dimensional nanotechnology, applied in the field of nanomaterials, can solve the problems of increasing the amount of carbon residue, and achieve the effects of increasing the amount of carbon residue, promoting retention, and high phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

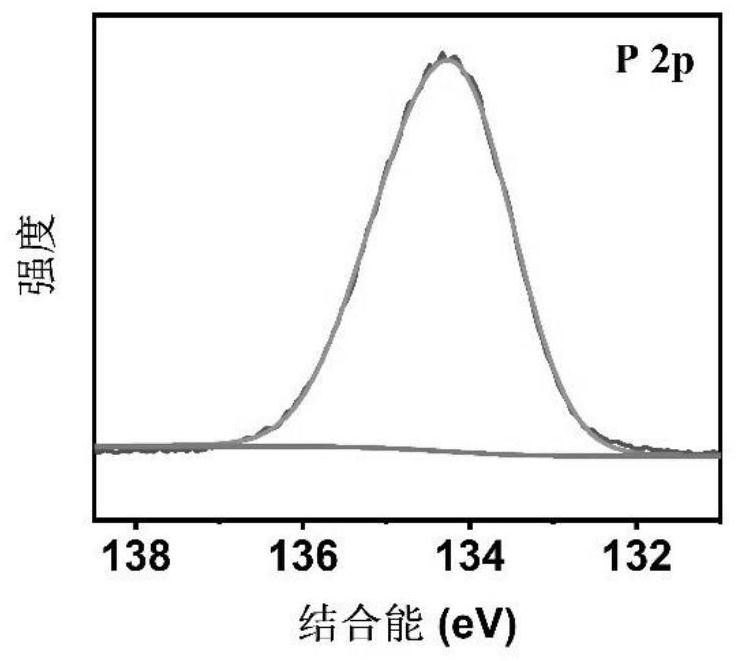

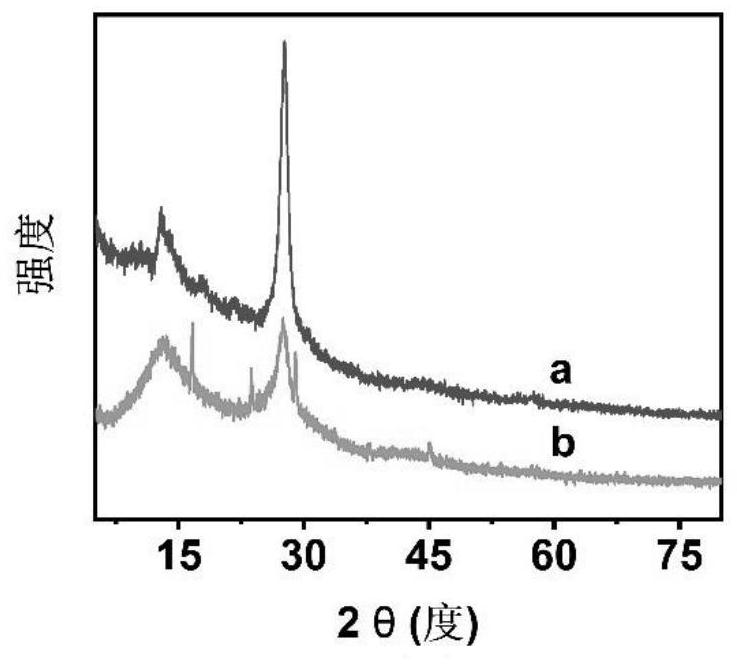

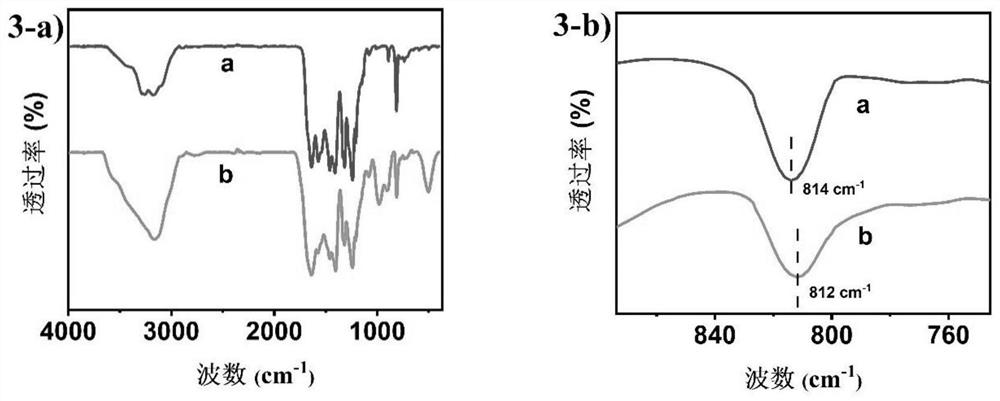

[0037] An embodiment of the preparation method of phosphorus-doped carbon nitride two-dimensional nanoparticles of the present invention, the method comprises the following steps:

[0038] (1) Stir thiourea and 2-aminoethylphosphonic acid at a frequency of 50 Hz for 3 minutes and mix evenly to obtain a mixed precursor; the mass ratio of thiourea to 2-aminoethylphosphonic acid is 1:0.2;

[0039] (2) Put the mixed precursor obtained in step (1) into a ceramic crucible and seal it, heat it to 400°C in a muffle furnace at a rate of 15°C / min and keep it warm for 3h, and after natural cooling, a block doped carbon;

[0040] (3) After pulverizing the massive doped carbon obtained in step (2) at a frequency of 50 Hz for 50 seconds in a high-speed pulverizer, the phosphorus-doped carbon nitride two-dimensional nanoparticles are obtained.

[0041] The phosphorus-doped carbon nitride two-dimensional nanoparticles are used to prepare flame-retardant water-based polyurethane, comprising t...

Embodiment 2

[0047] An embodiment of the preparation method of phosphorus-doped carbon nitride two-dimensional nanoparticles of the present invention, the method comprises the following steps:

[0048] (1) Stir melamine and sodium hypophosphite at a frequency of 50 Hz for 50 s and mix evenly to obtain a mixed precursor; the mass ratio of melamine and sodium hypophosphite is 1:0.09;

[0049] (2) Put the mixed precursor obtained in step (1) into a ceramic crucible and seal it, heat it to 600°C in a muffle furnace at a rate of 20°C / min and keep it warm for 2h, and after natural cooling, a block doped carbon;

[0050] (3) After pulverizing the massive doped carbon obtained in step (2) in a high-speed pulverizer at a frequency of 50 Hz for 1 min, the phosphorus-doped carbon nitride two-dimensional nanoparticles are obtained.

[0051] The preparation method of flame-retardant water-based polyurethane described in this embodiment is the same as that in Example 1.

Embodiment 3

[0053] An embodiment of the preparation method of phosphorus-doped carbon nitride two-dimensional nanoparticles of the present invention, the method comprises the following steps:

[0054] (1) Stir urea and phytic acid at a frequency of 50 Hz for 50 s and mix evenly to obtain a mixed precursor; the mass ratio of urea to phytic acid is 1:0.05;

[0055] (2) Put the mixed precursor obtained in step (1) into a ceramic crucible and seal it, heat it in a muffle furnace to 500°C at a rate of 10°C / min and keep it warm for 2h, and after natural cooling, a block doped carbon;

[0056] (3) After pulverizing the massive doped carbon obtained in step (2) at a frequency of 50 Hz in a high-speed pulverizer for 2 minutes, the phosphorus-doped carbon nitride two-dimensional nanoparticles are obtained.

[0057] The preparation method of flame-retardant water-based polyurethane described in this embodiment is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com