M-aminobenzoic acid spherical crystal and preparation method thereof

A technology of aminobenzoic acid and spherical crystals, which is applied in the preparation of cyanide reaction, chemical instruments and methods, and the preparation of organic compounds. Utilization, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

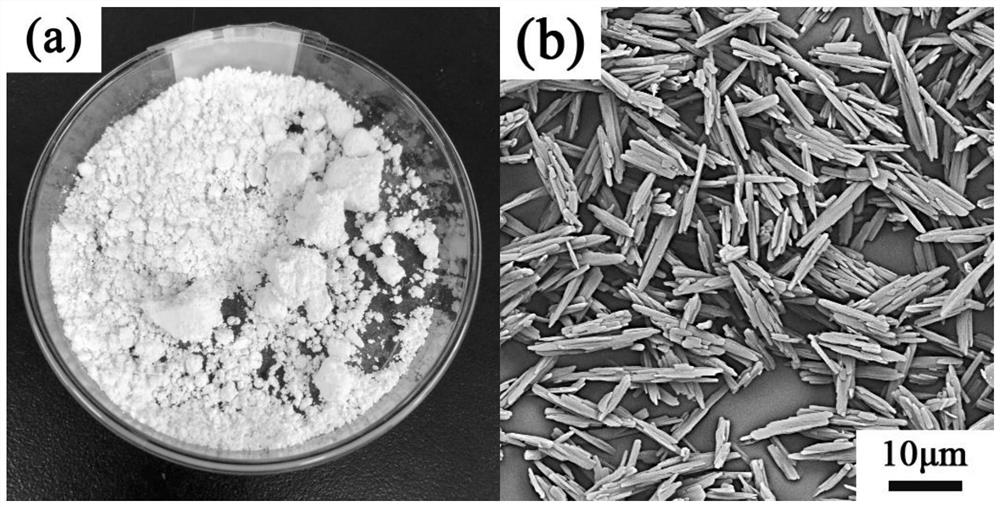

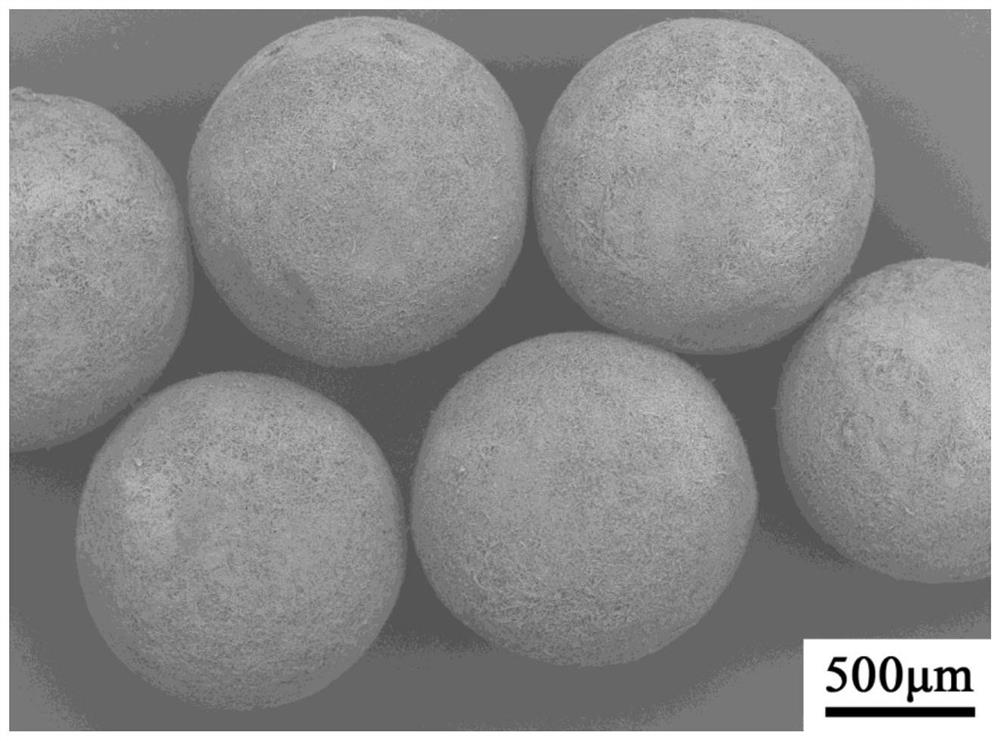

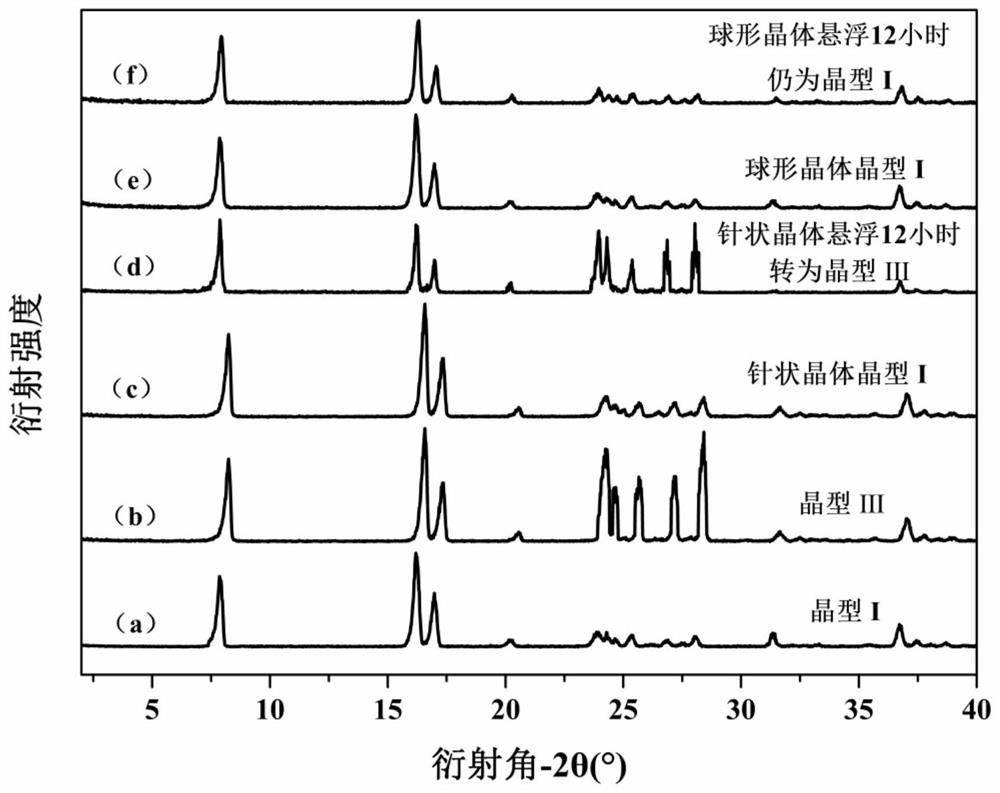

[0064] Dissolve 10g of m-aminobenzoic acid I crystal form raw material in 100g of isopropanol at 60°C and 250r / min stirring speed to prepare a m-aminobenzoic acid solution, the solution concentration is 0.091g / g solution, at 3°C / 10min Cooling rate Cool the solution to 10°C, continue to stir at 250r / min until the crystals appear, and continue to stir at a constant temperature for 40 minutes to coalesce the crystals into balls. At this time, the density of the crystal slurry is 0.078g / g solution, then filter the crystal slurry, wash with water, Air-dried at 50°C for 12 hours to obtain spherical crystals of m-aminobenzoic acid. The purity of the spherical crystals of m-aminobenzoic acid obtained after testing is 98.1%, and the volume average particle size is 1.22mm, as attached figure 2 As shown, the angle of repose is 25.8°, the fluidity of the product is greatly improved, and it has a significant improvement effect on the post-treatment of the product such as filtration, washi...

Embodiment 2

[0066] Dissolve 13g of m-aminobenzoic acid I crystal form raw material in 100g of ethylene glycol at 65°C and a stirring rate of 300r / min to prepare a m-aminobenzoic acid solution, the solution concentration is 0.115g / g solution, at 5°C / 10min Lower the temperature of the solution to 5°C, continue to stir at 300r / min until the crystals appear, and continue to stir at a constant temperature for 60 minutes to make the crystals coalesce into balls. At this time, the density of the crystal slurry is 0.080g / g solution, then filter the crystal slurry and wash with water , Blast drying at 50°C for 12 hours to obtain spherical crystals of m-aminobenzoic acid. The purity of the spherical crystals of m-aminobenzoic acid obtained through testing is 98.0%, the volume average particle size is 0.63mm, and the angle of repose is 24.4°. treatment, there is a significant improvement; the agglomeration rate of spherical crystals is 6.0%, which is far less than 58-64% of needle crystals; the tap ...

Embodiment 3

[0068] Dissolve 11g of m-aminobenzoic acid I crystal form raw material in 100g of ethanol at 50°C and a stirring rate of 200r / min to prepare a m-aminobenzoic acid solution. Cool the solution to 10°C at a high speed, continue to stir at 200r / min until the crystals appear, and continue to stir at a constant temperature for 50 minutes to coalesce the crystals into balls. At this time, the density of the crystal slurry is 0.080g / g solution, then filter the crystal slurry, wash with water, °C blast drying for 10 hours to obtain spherical crystals of m-aminobenzoic acid. The purity of the spherical crystals of m-aminobenzoic acid obtained through testing is 98.2%, the volume average particle size is 0.55mm, and the angle of repose is 27.7°. treatment, there is a significant improvement; the agglomeration rate of spherical crystals is 6.5%, which is far less than 58-64% of needle-shaped crystals; the tap density of spherical crystals is 0.35g / cm 3 , which improves the storage and tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com