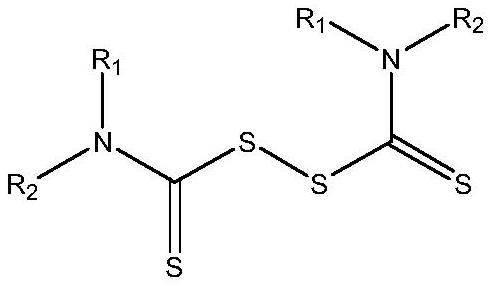

Method for preparing tetraalkyl thiuram disulfide through photocatalytic oxidation

A technology of photocatalytic oxidation and tetrahydrocarbyl thiuram, applied in the directions of organic chemistry methods, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of stable quality, avoiding dissolution loss and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

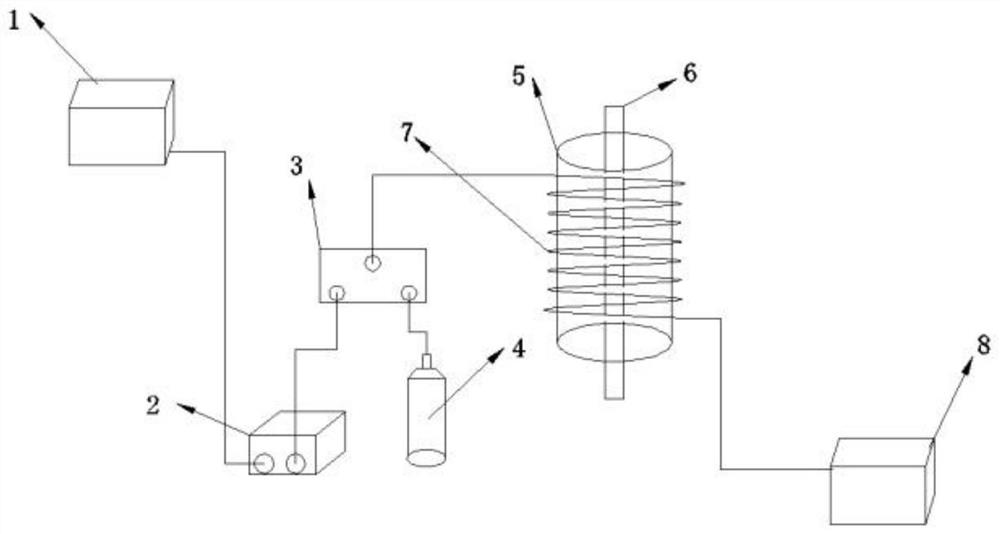

Method used

Image

Examples

Embodiment 1

[0047] Add 7.39g of diethylamine, 90mL of absolute ethanol, and 0.052g of hematoxylin into a 250ml beaker with a cover. Turn on the stirring, control the temperature at 20-30°C, slowly add 7.81g of carbon disulfide, complete the addition in about 1 minute, and stir for 5 minutes to react. Turn on the 12W LED blue light source, the light source is located in the center of the liquid surface, 5cm above the liquid surface, turn on the Sensen ct-201 air pump (with bubble disc) to feed air into the reaction solution, light reaction for 2min, stop the aeration and the reaction is over. Ethanol was distilled off under reduced pressure and dried to obtain 14.68 g of white tetraethylthiuram disulfide crystals, with a yield of 98.99% and a purity of 99.95% as detected by liquid chromatography.

Embodiment 2

[0049]Add 36.95g of diethylamine, 0.259g of hematoxylin, and 250ml of absolute ethanol into a 500mL beaker with a cover. Turn on the stirring, control the temperature at 20-30°C, slowly add 39.05g of carbon disulfide, complete the addition in about 30 minutes, and stir for 10 minutes to react. Turn on the 12w LED blue light source, the light source is located in the center of the liquid surface, 5cm above the liquid surface, turn on the Sensen ct-201 air pump (with bubble disc) to pass air into the reaction solution for 10 minutes, stop the aeration and the reaction is over. Filter and collect the mother liquor, and dry to obtain 63.80 g of white tetraethylthiuram disulfide crystals. The yield was 86.04%, and the purity detected by liquid chromatography was 99.99%.

Embodiment 3

[0051] 36.95g of diethylamine and the mother liquor collected in Example 2 were added to a 500mL beaker with a cover. Turn on the stirring, at 20-30°C, slowly add 39.05g of carbon disulfide, complete the addition in about 30 minutes, and stir for 10 minutes to react. Turn on the 12w LED blue light source, the light source is located in the center of the liquid surface, 5cm higher than the liquid surface, turn on the Sensen ct-201 air pump (with bubble disc) to pass air into the reaction solution for 10 minutes, and stop the ventilation to complete the reaction. The mother liquor was collected by filtration and dried to obtain 74.21 g of white tetraethylthiuram disulfide crystals. The yield was 100.07%, and the purity detected by liquid chromatography was 99.98%.

[0052] After rectifying the mother liquor to recover ethanol, 10.26 g of white crystal tetraethylthiuram disulfide was obtained, and the purity detected by liquid chromatography was 99.95%. Combining the product qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com