Preparation method and application of antibacterial nano graphene oxide inclusion TiO2 acrylic resin

A nano-graphite oxide, acrylic resin technology, used in coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problems of low gloss, poor gloss retention, and insufficient fullness of paint films. , to achieve the effect of not polluting the environment, strong practicality, excellent light resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

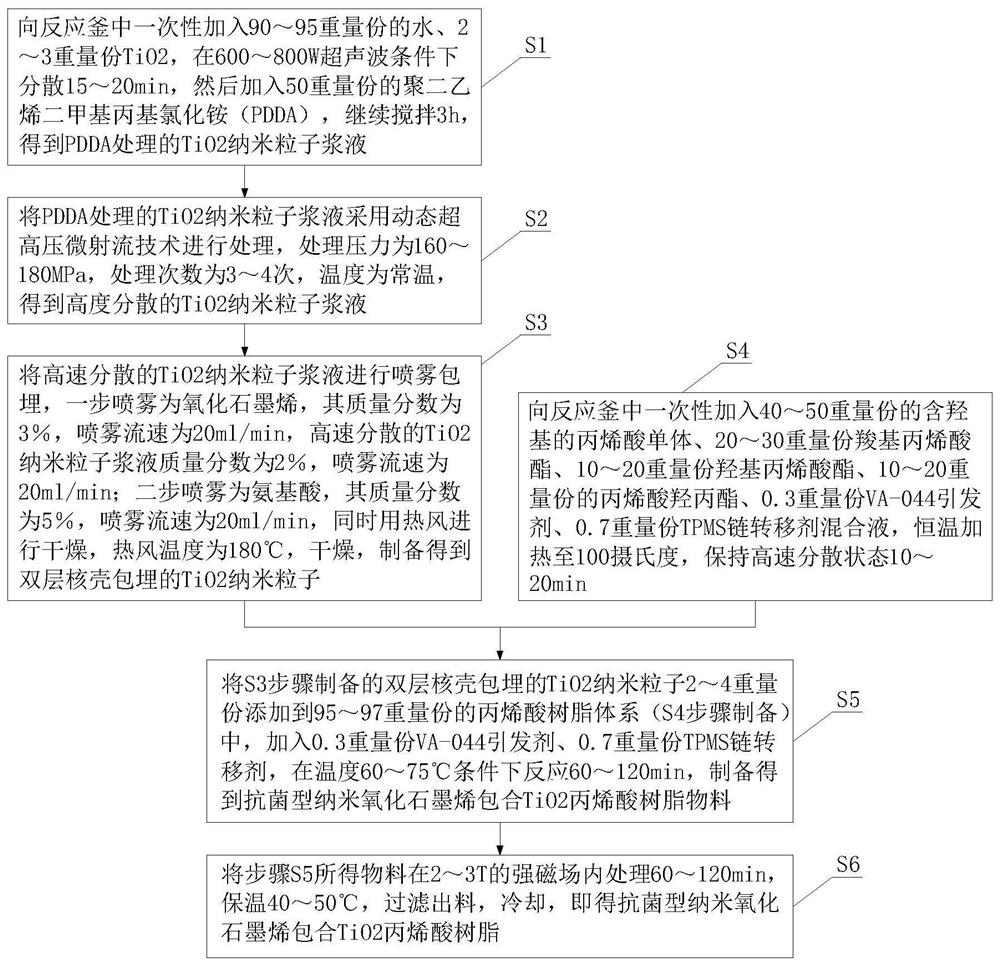

[0029] see figure 1 , the present invention provides the following technical scheme: a kind of antibacterial nanometer graphene oxide clathrate TiO Acrylic resin preparation method, this preparation method comprises the following steps:

[0030]Step S1: Add 90 parts by weight of water and 3 parts by weight of TiO to the reactor at one time, disperse for 20 minutes under 800W ultrasonic conditions, and then add 50 parts by weight of polydiethylene dimethyl propyl ammonium chloride (PDDA), Continue to stir for 3h, obtain the TiO that PDDA processes Nano particle slurry;

[0031] Step S2: Treat the PDDA-treated TiO2 nanoparticle slurry with dynamic ultra-high pressure micro-jet technology, the treatment pressure is 160 MPa, the number of treatments is 3 times, and the temperature is normal temperature to obtain a highly dispersed TiO2 nanoparticle slurry;

[0032] Step S3: Spray and embed the high-speed dispersed TiO2 nanoparticle slurry, one-step spraying is graphene oxide, its...

Embodiment 2

[0041] see figure 1 , the present invention provides the following technical scheme: a kind of antibacterial nanometer graphene oxide clathrate TiO Acrylic resin preparation method, this preparation method comprises the following steps:

[0042] Step S1: Add 95 parts by weight of water and 2 parts by weight of TiO to the reactor at one time, disperse for 20 minutes under 600W ultrasonic conditions, and then add 50 parts by weight of polydiethylene dimethyl propyl ammonium chloride (PDDA), Continue to stir for 3h, obtain the TiO that PDDA processes Nano particle slurry;

[0043] Step S2: Treat the PDDA-treated TiO2 nanoparticle slurry with dynamic ultra-high pressure micro-jet technology, the treatment pressure is 180 MPa, the number of treatments is 4 times, and the temperature is normal temperature to obtain a highly dispersed TiO2 nanoparticle slurry;

[0044] Step S3: Spray and embed the high-speed dispersed TiO2 nanoparticle slurry, one-step spraying is graphene oxide, it...

Embodiment 3

[0053] see figure 1 , the present invention provides the following technical scheme: a kind of antibacterial nanometer graphene oxide clathrate TiO Acrylic resin preparation method, this preparation method comprises the following steps:

[0054] Step S1: Add 92 parts by weight of water and 3 parts by weight of TiO to the reactor at one time, disperse for 18 minutes under 700W ultrasonic conditions, and then add 50 parts by weight of polydiethylene dimethyl propyl ammonium chloride (PDDA), Continue to stir for 3h, obtain the TiO that PDDA processes Nano particle slurry;

[0055] Step S2: Treat the PDDA-treated TiO2 nanoparticle slurry with dynamic ultra-high pressure micro-jet technology, the treatment pressure is 170 MPa, the number of treatments is 3 times, and the temperature is normal temperature to obtain a highly dispersed TiO2 nanoparticle slurry;

[0056] Step S3: Spray and embed the high-speed dispersed TiO2 nanoparticle slurry, one-step spraying is graphene oxide, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com