Film formation material for lithography, composition for film formation for lithography, underlayer film for lithography, and pattern formation method

A technology of lithography and compounds, which is applied in the processing of photosensitive materials, photosensitive materials for photomechanical equipment, coatings, etc., can solve problems such as difficulty in obtaining, resolution problems, and collapse of resist patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

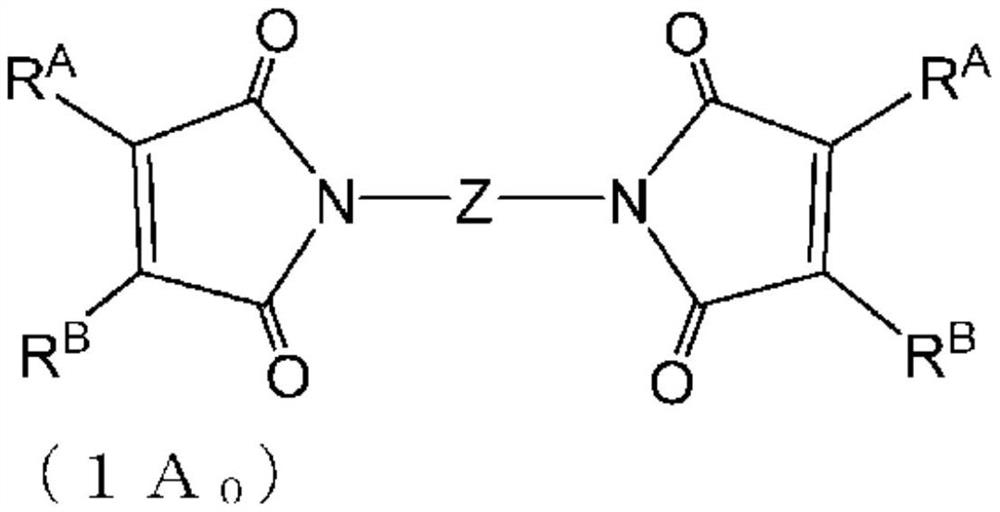

[0371] Separately, as the biscitraconimide compound, 5 parts by mass of BAPP citraconimide obtained in Synthesis Example 1 was used, and as the bismaleimide compound, bismaleimide represented by the following formula was used: 5 parts by mass of imide (BMI-80; manufactured by K.I Chemical Industry Co., Ltd.) was used as a film-forming material for photolithography.

[0372]

[0373] As a result of the thermogravimetric measurement, the amount of thermogravimetric decrease at 400° C. of the obtained film-forming material for lithography was less than 10% (evaluation A). In addition, when the solubility in PGMEA was evaluated, it was 20% by mass or more (evaluation S), and it was evaluated that the obtained film-forming material for lithography had sufficient solubility.

[0374] A film-forming composition for lithography was prepared by adding 90 parts by mass of PGMEA as a solvent to 10 parts by mass of the aforementioned film-forming material for lithography, and stirring ...

Embodiment 1-2 and 1-3

[0376] Except having changed the quantity of BAPP citraconimide and BMI-80 respectively as shown in Table 1, it carried out similarly to Example 1, and prepared the composition for film formation for photolithography.

Embodiment 2

[0378] Separately, as the biscitraconimide compound, 5 parts by mass of APB-N citraconimide obtained in Synthesis Example 2-1 was used, and as the bismaleimide compound, Synthesis Example 2- 5 parts by mass of the APB-N maleimide obtained in 2 was prepared as a film-forming material for photolithography.

[0379] As a result of the thermogravimetric measurement, the amount of thermogravimetric decrease at 400° C. of the obtained film-forming material for lithography was less than 10% (evaluation A). In addition, when the solubility in PGMEA was evaluated, it was 10 mass % or more and less than 20 mass % (evaluation A), and it was evaluated that the obtained film-forming material for lithography had sufficient solubility.

[0380] A film-forming composition for photolithography was prepared in the same manner as in Example 1 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com