Degradable antibacterial nanofiber non-woven fabric composite filter material and preparation method thereof

A technology of nanofibers and composite filter materials, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of being unable to face the environment, short service life, lack of antibacterial, antiviral, etc., to achieve improved killing effect, reduction of filtration resistance, effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The present invention will be further described below with reference to the accompanying drawings. The following examples are for more clearly explaining the technical solutions of the present invention without limiting the scope of the invention.

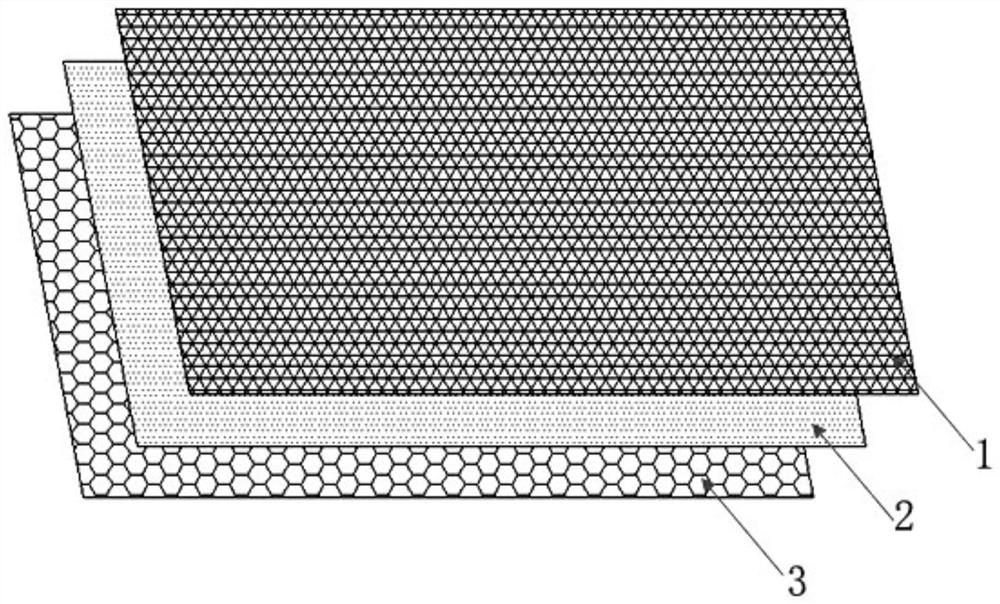

[0026]Such asfigure 1As shown, the present invention provides a degradable antibacterial nanofiber-free nonwoven composite filter, including a three-layer structure, and the first layer of wind direction is a nanofiber filter layer 1, and the second layer is a nanomaterial antibacterial layer 2, The three layers are the base layer 3.

[0027]The nanofiber filter layer 1 is a porous film formed by electrospray through electrostatic spinning, the multi-well film having a fiber diameter of from 50 to 1000 nm, and the porous film is 400 to 5000 nm, and the porosity is 80%. The thickness is 1 to 5 μm. The spinning stock solution is a solution of solvent to a solvent having a solution of 7% to 25%, the degradable polymer material to polylactic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com