Preparation method of coralline MoS2 photocatalyst and MoS2-BiOBr heterojunction composite photocatalytic material

A technology of composite photocatalysis and photocatalysis, applied in the field of photocatalytic materials, can solve the problems of reducing the number of exposed active sites on the edge and reducing photocatalytic activity, and achieve the goal of improving photocatalytic efficiency, strong structural continuity and high catalytic rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

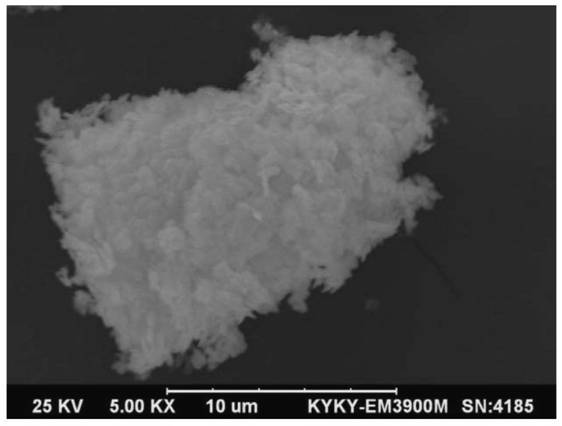

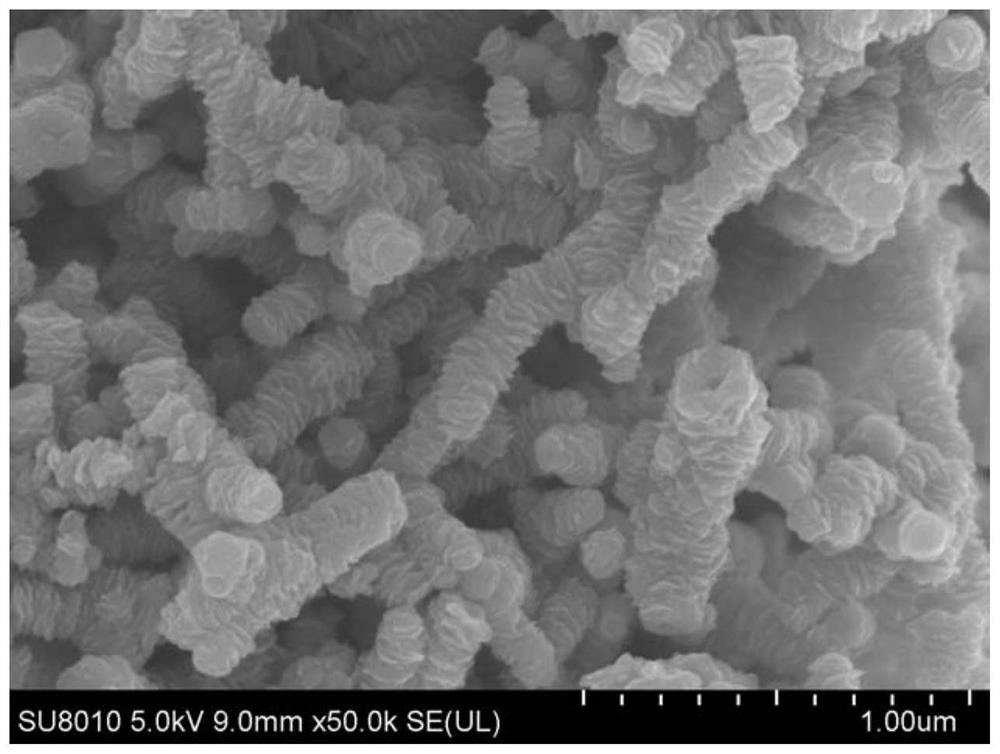

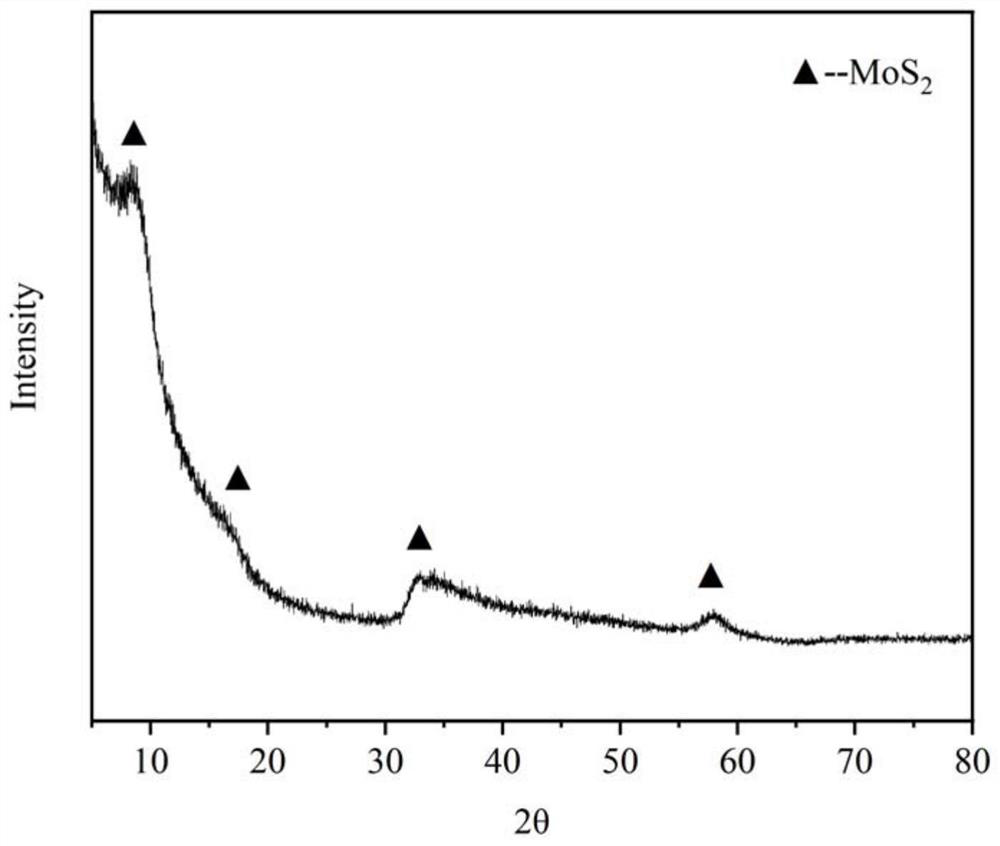

[0029]This embodiment is a coral-like nano MoS2The preparation method of the photocatalyst is as follows:

[0030]Dissolve 0.0673g of ammonium molybdate pentahydrate, 0.0652g of thiourea, and 0.0366g of citric acid in 50mL of deionized water, stir and mix evenly with magnetic force, then transfer to a hydrothermal kettle for hydrothermal reaction, and hydrothermal reaction at 200℃ for 18h ; After the reaction is complete, cool to room temperature naturally, and the reaction product is washed alternately with distilled water and absolute ethanol, and dried at 80°C to obtain coral-like nano MoS2Photocatalytic materials.

Embodiment 2

[0032]This embodiment is a coral-like nano MoS2The preparation method of the photocatalyst is as follows:

[0033]Dissolve 0.0673g of ammonium molybdate pentahydrate, 0.0760g of thiourea, and 0.0576g of citric acid in 50mL of deionized water, stir and mix evenly with magnetic force, transfer to a hydrothermal kettle for hydrothermal reaction, and hydrothermal reaction at 180℃ for 24h ; After the reaction is complete, cool to room temperature naturally, and the reaction product is washed alternately with distilled water and absolute ethanol, and dried at 80°C to obtain coral-like nano MoS2Photocatalytic materials.

Embodiment 3

[0035]A MoS of this embodiment2-BiOBr heterojunction composite photocatalytic material preparation method, the steps are as follows:

[0036](1) Dissolve 0.9702g bismuth nitrate pentahydrate in 60mL deionized water to form a bismuth nitrate solution, dissolve 0.714g potassium bromide in 20mL deionized water to form a potassium bromide solution, and then add the above potassium bromide solution to the bismuth nitrate In the solution, stir and mix evenly, then transfer to a PTFE hydrothermal kettle for hydrothermal reaction at 140°C for 24 hours. After the reaction is complete, it is naturally cooled to room temperature. The reaction product is washed alternately with distilled water and absolute ethanol. Dry at 80℃, and obtain BiOBr after grinding;

[0037](2) Dissolve 0.0673g of ammonium molybdate pentahydrate, 0.0652g of thiourea, and 0.0366g of citric acid in 40mL of deionized water, add the above BiOBr and stir to dissolve, after ultrasonic dispersion, transfer to a hydrothermal kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com