Bimetallic coni-zif-derived coni@cn catalysts and their preparation and catalytic hydrogenation applications

A catalyst, bimetallic technology, applied in chemical instruments and methods, physical/chemical process catalysts, preparation of oxygen-containing functional groups reduction, etc. Effect

Active Publication Date: 2022-06-03

HUBEI UNIV

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the Chinese patent CN1546444A, the catalyst used is to load Pd-B on NaY, MCM41, β molecular sieve, and metal oxides by the equal volume impregnation method. Although the hydrogenation activity is high, the expensive noble metal catalyst is used.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

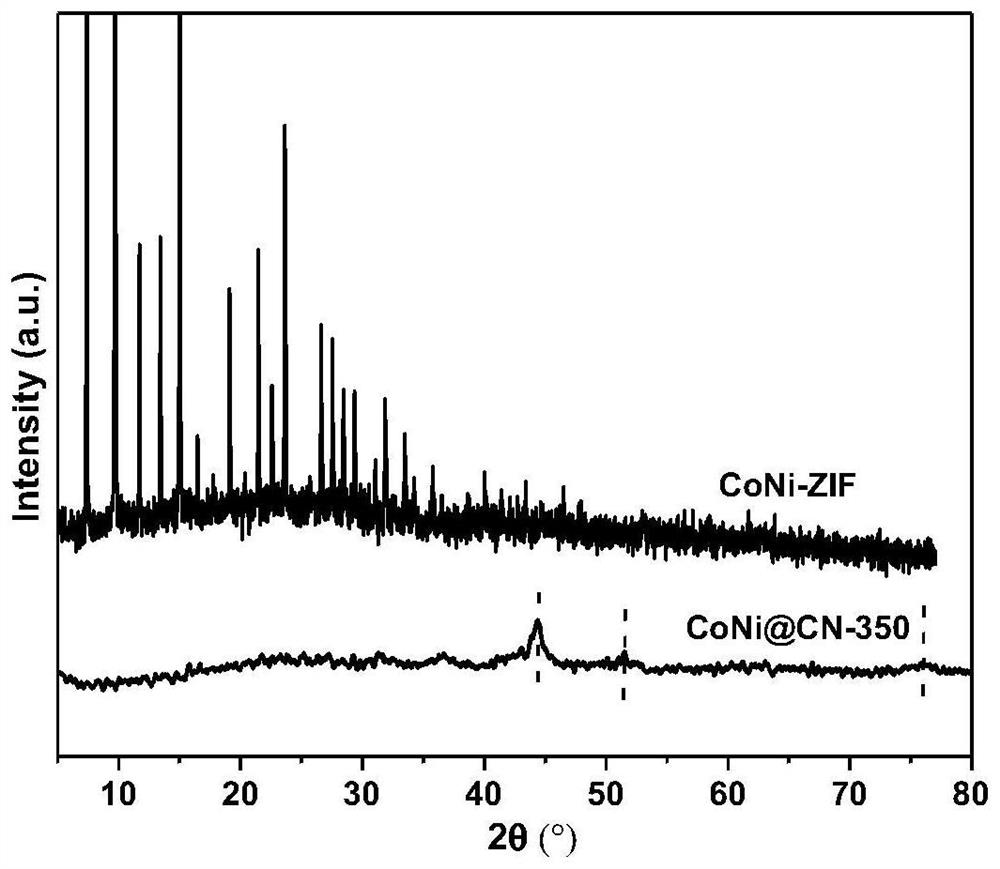

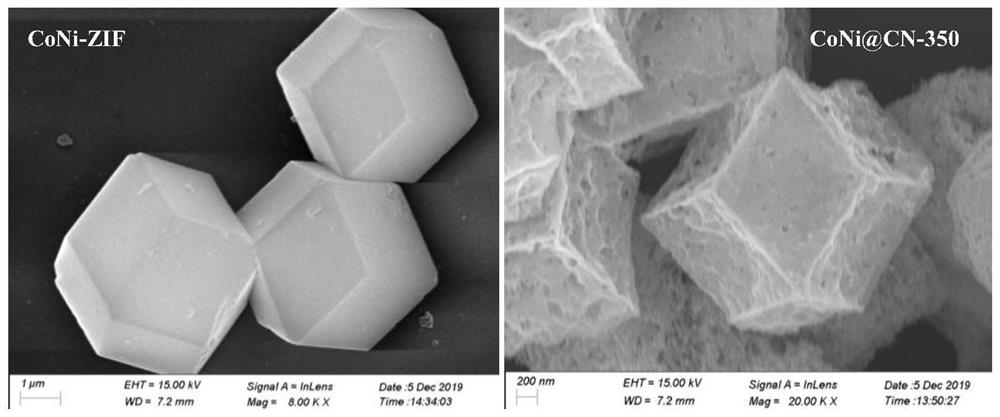

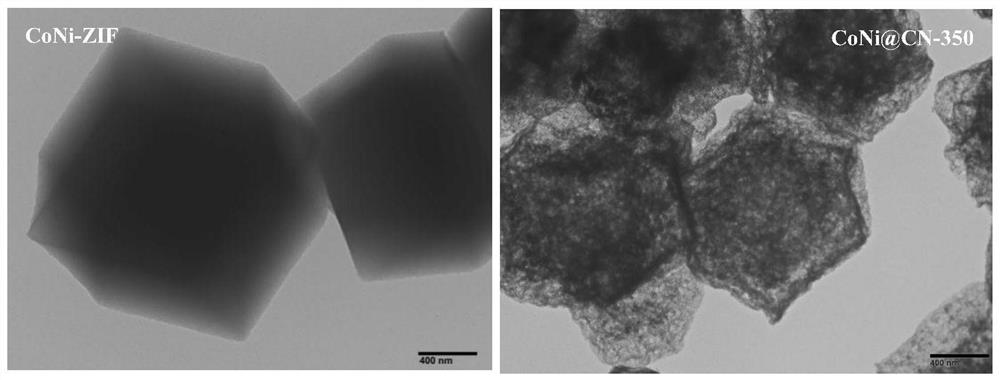

The invention discloses a CoNi@CN catalyst derived from bimetallic CoNi-ZIF and its preparation method and its application in catalytic epoxide hydrogenation. The preparation method comprises the following steps: after fully mixing cobalt salt, nickel salt and alcohol, Obtain solution A; mix P123 and alcohol fully to obtain solution B; add solution B to solution A in batches to obtain mixed solution C and stir evenly; mix imidazoles and alcohol evenly and add to solution C to obtain Mixed solution D; Mixed solution D is fully stirred and reacted at alcohol reflux temperature, obtains CoNi-ZIF metal-organic framework material; H 2 The hydrogenation catalyst is obtained by pyrolysis reduction treatment. The catalyst prepared by the present invention has low cost, high hydrogenation reaction conversion rate and good product selectivity, and can be applied to catalyze epoxy compounds and H 2 The hydrogenation reaction prepares aromatic alcohols, alicyclic alcohols and aliphatic alcohols, which greatly improves the conversion rate of epoxy compounds and the selectivity of alcohols.

Description

Bimetallic CoNi‑ZIF-derived CoNi@CN catalyst and its preparation method and catalysis Hydrogenation applications technical field The present invention relates to the field of epoxide hydrogenation, specifically refers to the CoNi@CN catalyst derived from bimetallic CoNi-ZIF The preparation method thereof and the application of catalytic epoxide hydrogenation. Background technique Alcohol is a kind of important biomass platform compound, it is the fine chemical industry such as detergent, surfactant, plastic plasticizer. The basic raw material of the product, with a large amount and high added value, is widely used in medicine, food, cosmetics, plastics, antioxidants and other industries middle. Hydrogenation is a kind of important means that epoxy compound prepares alcohol compound, and preparing cyclohexanol with epoxy cyclohexane is For example, the current technology mainly prepares cyclohexanol by reacting epoxy cyclohexane with a hydrogenation reagent, and t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J27/24C07C29/132C07C35/08

CPCB01J27/24C07C29/132C07C35/08Y02P20/584

Inventor 鲁新环王晨龙夏清华王贝贝周丹

Owner HUBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com