A kind of preparation method and application of anti-corrosion auxiliary agent for graphene-based composite materials

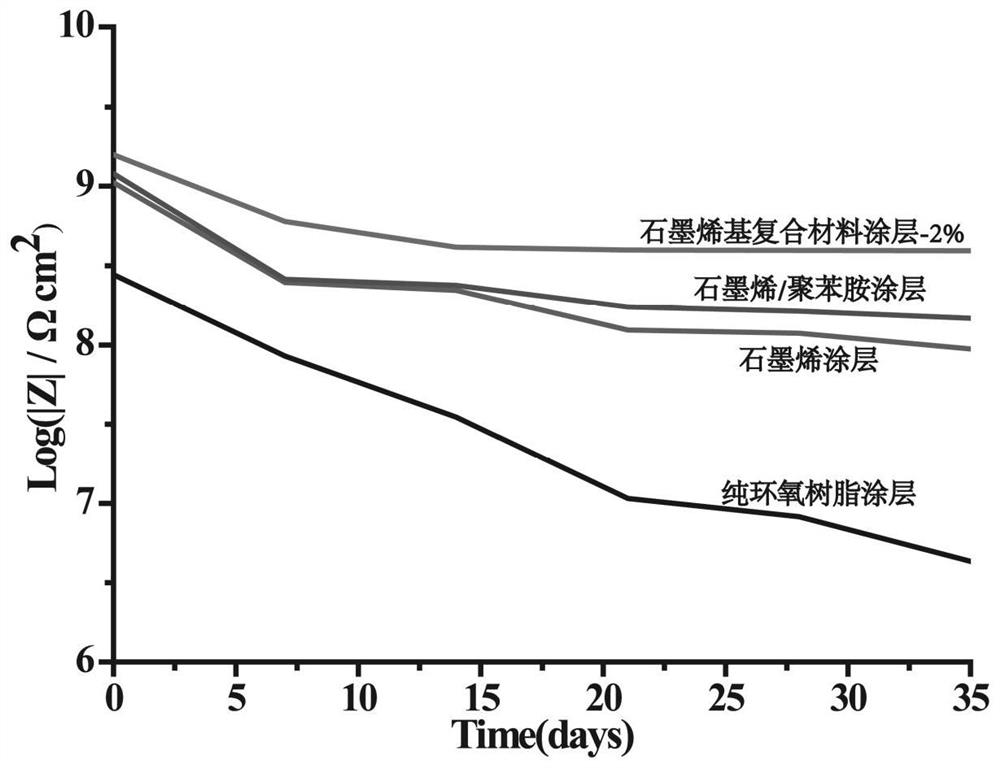

A composite material and graphene-based technology, applied in anti-corrosion coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor dispersion of graphene and single anti-corrosion performance, so as to improve compatibility and improve Anti-corrosion performance, the effect of prolonging the diffusion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

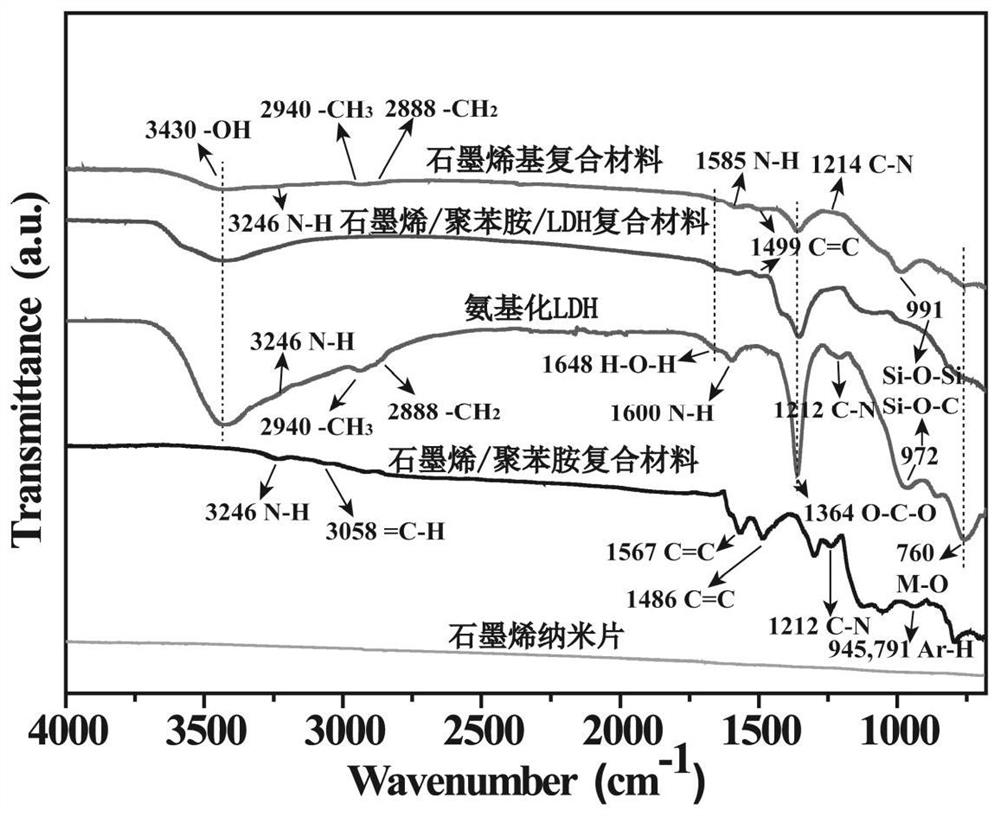

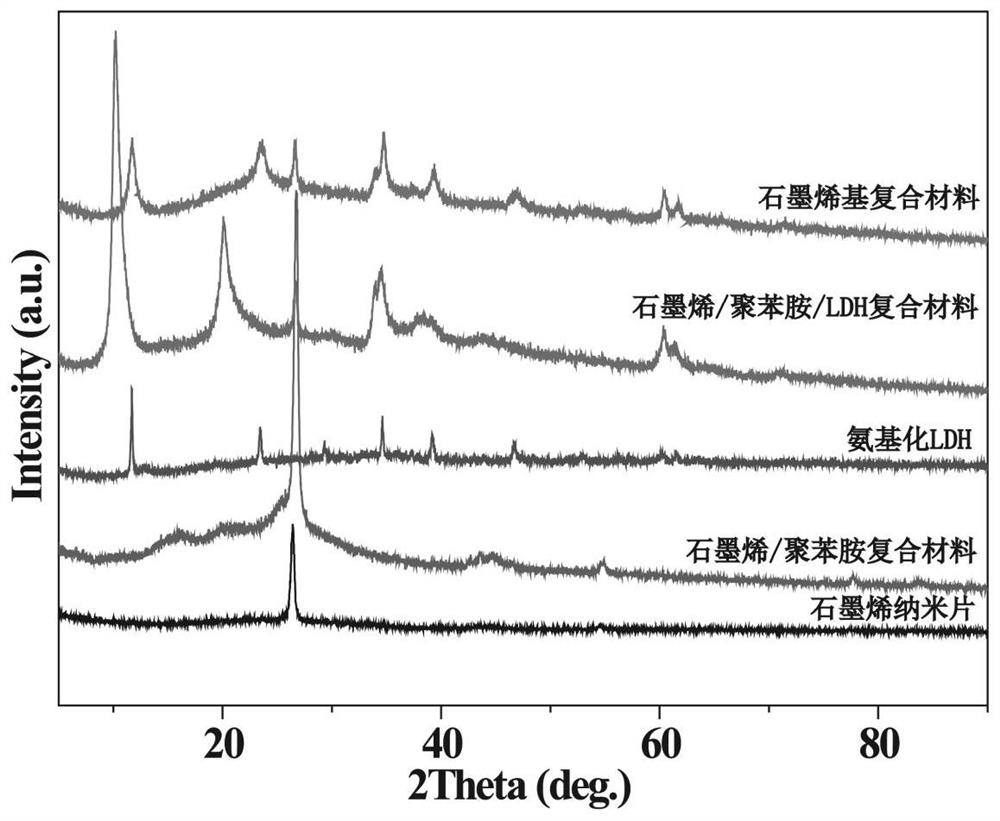

[0033] 1. Preparation of graphene-based composites

[0034] (1) Preparation of graphene / polyaniline composites

[0035] Add 0.1 g of graphene nanosheets and 90 mL of deionized water to a round-bottomed flask, sonicate at room temperature for 5 h, add 0.2 g of aniline monomer and 1.5 g of phytic acid solution (70 wt%), stir at 0°C for 4 h, and initiate Ammonium persulfate and 0.5g phytic acid solution (70wt%) were dissolved in 30mL of deionized water, and were added dropwise to the above dispersion liquid at a rate of 3 seconds per drop at 0°C, kept stirring for 8 hours, and then successively filtered by suction, Washing with deionized water and drying to obtain the graphene / polyaniline composite material. (2) Preparation of graphene / polyaniline / LDH composite material

[0036] Add 0.1 g of graphene / polyaniline composite material and 70 mL of deionized water into a three-neck round-bottomed flask, ultrasonicate at room temperature for 2 h, add 2.08 g of zinc nitrate hexahydrat...

Embodiment 2

[0051] 1. Same as embodiment 1.

[0052] 2. Weigh 50g of polyurethane resin, add 20g of butyl acetate and 0.5g of graphene-based composite material, stir for 1 hour, add 25g of polyisocyanate curing agent, and stir for 1 hour to obtain graphene-based anti-corrosion polyurethane resin coating.

Embodiment 3

[0054] 1. Same as embodiment 1.

[0055] 2. Weigh 50g of phenolic resin, 0.75g of graphene-based composite material, 10g of butanol and 15g of xylene, stir for 1 hour, add 5g of polyamide curing agent, and stir for 30 minutes to obtain a graphene-based anti-corrosion phenolic resin coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com