A Heat Treatment Process for Strengthening and Toughening Iron-Based Deformed Superalloys

A technology of deforming superalloys and strengthening and toughening, which is applied in the field of high-temperature metal structural materials, can solve the problems of limited increase in material costs, and achieve the effect of promoting the precipitation of precipitated phases and high nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]The alloy is smelted in a vacuum induction furnace, and the obtained alloy includes: Ni: 36%, Cr: 16%, Mn: 1.0%, Si: 0.05%, C: 0.06%, Mo: 0.8%; W: 0.4% , Ti: 2.1%; Al: 1.4%, and the balance is Fe. The alloy ingot is homogenized at 1170°C for 30 hours, and then thermally deformed at 1050°C. The total deformation is not less than 60%, and the final pass deformation is higher than 25%.

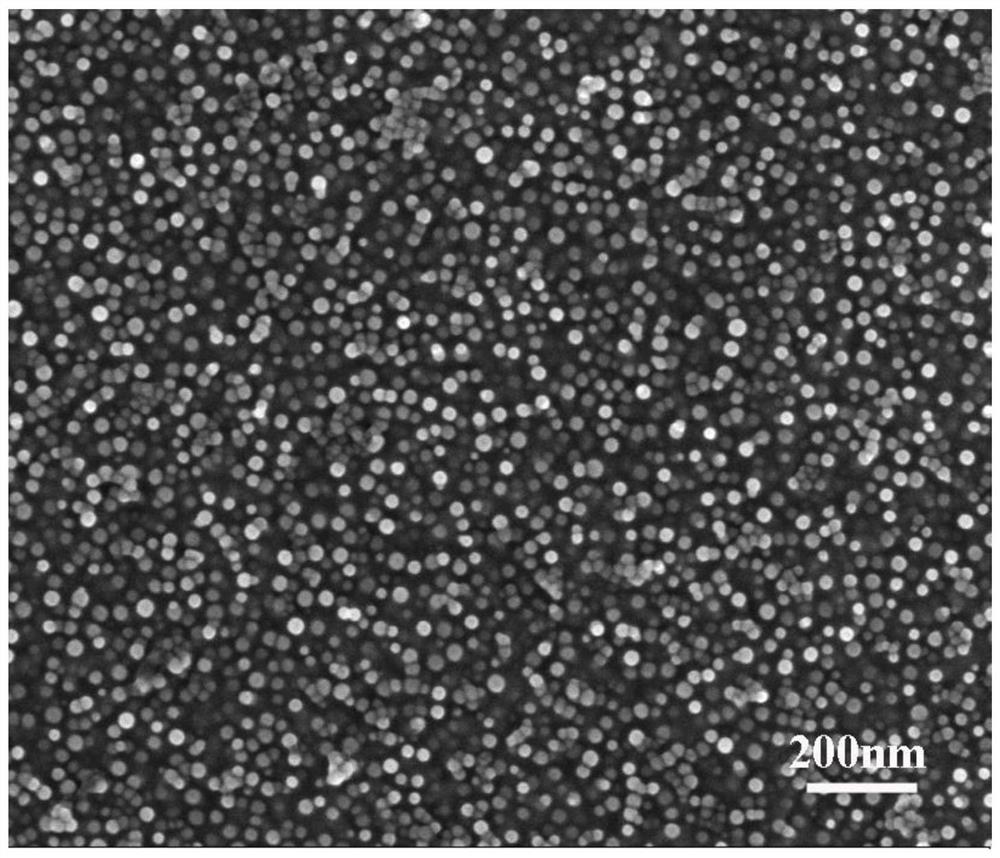

[0036] After the deformation of the alloy is completed, two-step solution treatment is carried out first, and the temperature is raised to 900°C at a rate of 10°C / min for 0.5 hours. Then, after heating at a rate of 10 °C / min to 900 °C for 0.5 hours, heating at a rate of 5 °C / min to 1000 °C for 0.5 hours and then water cooling. After the solution treatment is completed, the alloy is heated to 650°C and kept for 8 hours, and then air-cooled after completion. Finally, the alloy was heated to 800°C for 4 hours and cooled in air. Ni in the alloy after completion 3 The volume fraction of the ...

Embodiment 2

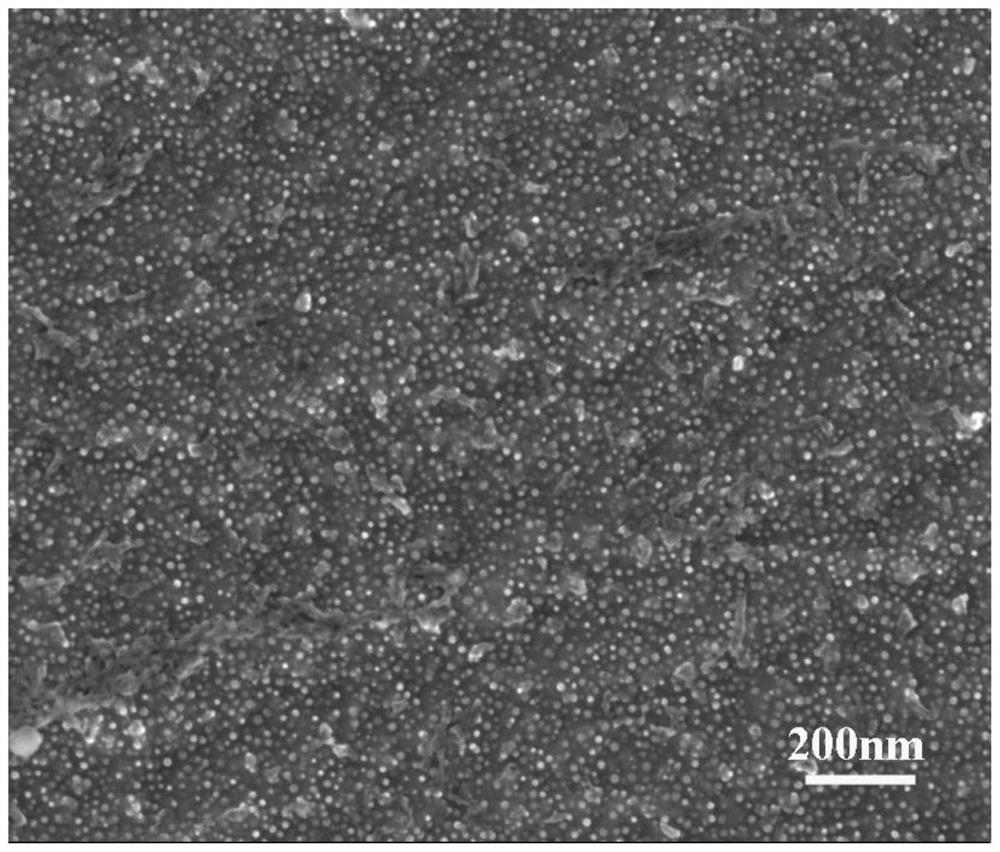

[0045] The alloy is smelted in a vacuum induction furnace, and the deformed alloy obtained includes: Ni: 25%, Cr: 15%, Mo: 0.5%; W: 0.8%, Ti: 2.5%; Al: 1.6%, Mn: 0.1%, Nb: 0.1%, Co: 1%, C: 0.03%, B: 0.001%, and the balance is Fe. The alloy ingot is homogenized at 1100°C for 50 hours, and then thermally deformed at 1020°C. The total deformation is not less than 60%, and the final pass deformation is higher than 25%.

[0046] Heat the deformed alloy from room temperature to 900°C at a rate of 10°C / min, and keep it warm for 0.5 hours, then continue to heat it up to 50°C above the carbide dissolution temperature at a rate of 5°C / min, hold it for 0.5 hours and then quench it with water cooling to room temperature;

[0047] Heat the treated alloy from room temperature to 900°C at a rate of 10°C / min, and keep it warm for 0.5 hours, then continue to heat it up to 50°C below the carbide precipitation temperature at a rate of 5°C / min, and hold it for 1 hour Cool to room temperature by...

Embodiment 3

[0051] The alloy is smelted in a vacuum induction furnace, and the deformed alloy obtained includes: Ni: 39%, Cr: 18%, Mo: 1%; W: 0.1%, Ti: 1.8%; Al: 1.2%, Mn: 0.5%, Co: 2%, Si: 0.02%, C: 0.1%, B: 0.005%, P: 0.01%, and the balance is Fe. The alloy ingot is homogenized at 1120°C for 45 hours, and then thermally deformed at 1120°C. The total deformation is not less than 60%, and the final pass deformation is higher than 25%.

[0052] Heat the deformed alloy from room temperature to 900°C at a rate of 10°C / min, and keep it warm for 0.5 hours, then continue to heat it up to 150°C above the carbide dissolution temperature at a rate of 5°C / min, hold it for 1 hour, and then quench it with water cooling to room temperature;

[0053] Heat the treated alloy from room temperature to 900°C at a rate of 10°C / min, and keep it warm for 0.5 hours, then continue to heat it up to 100°C below the carbide precipitation temperature at a rate of 5°C / min, and hold it for 0.5 hours Cool to room tem...

PUM

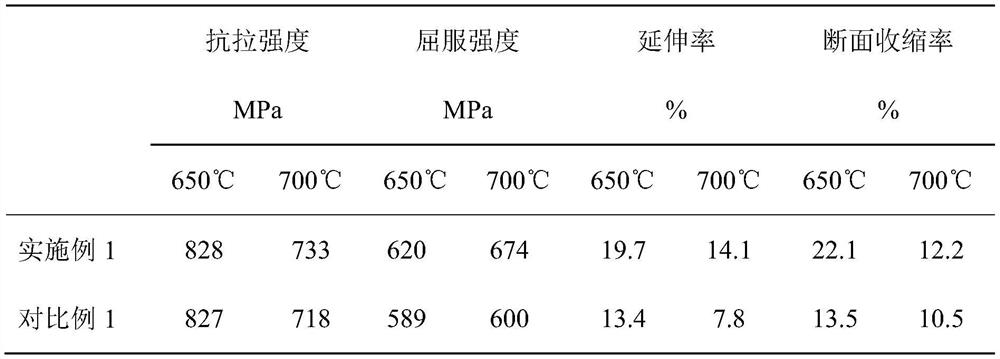

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com