An electrochemical aptamer sensor for ampicillin detection

An aptamer sensor and ampicillin technology, applied in the field of biosensors, can solve the problems of low specificity, sensitivity, and high cost, and achieve the effects of improved sensitivity, simple electrodes, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

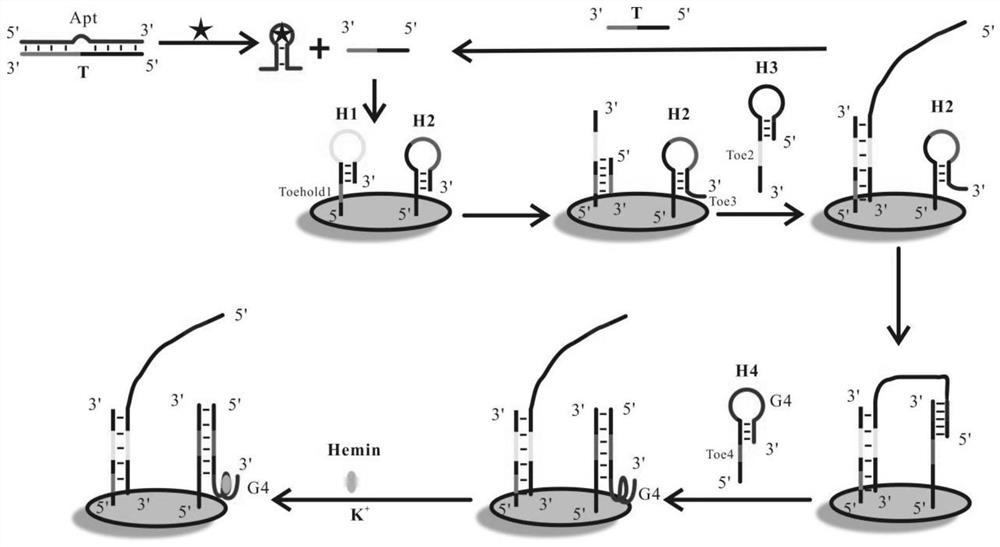

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Preparation of Apt-T Hybrid Chain

[0039] 2 μL of 100 μM aptamer Apt, 2 μL of 100 μM T chain, 2 μL 5×PBS buffer, 4 μL ddH 2 Mix O evenly, react in a water bath at 95 °C for 5 min and gradually cool to room temperature to obtain 10 μM Apt-T hybrid chain solution.

Embodiment 2

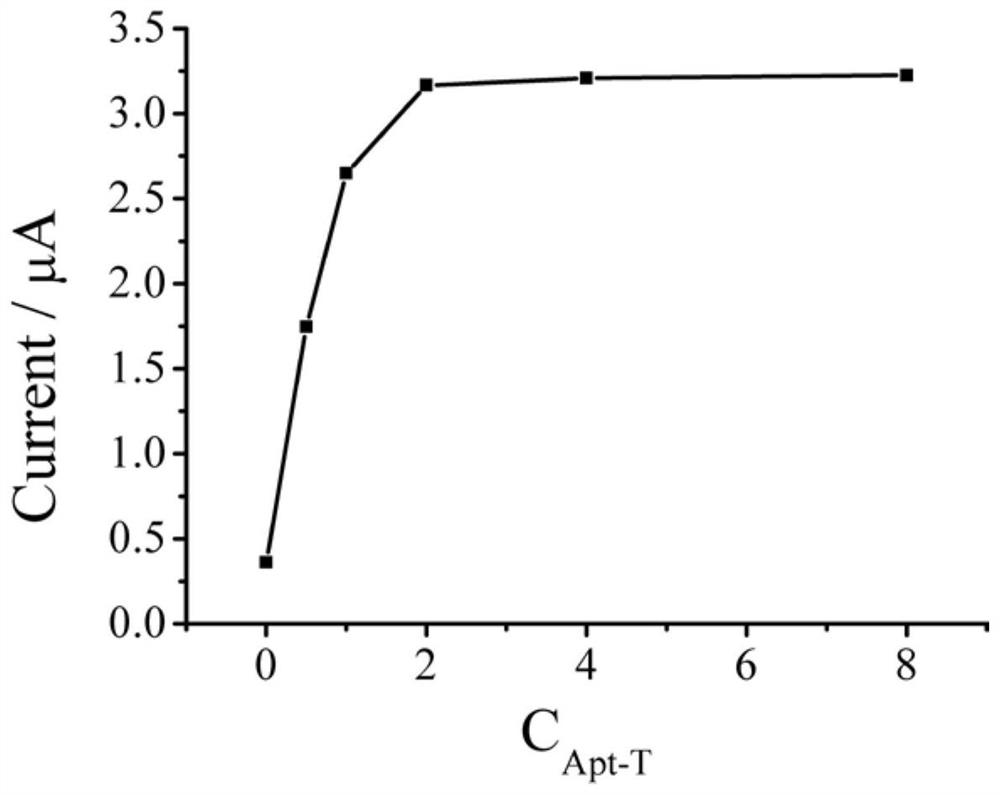

[0040] Example 2 Apt-T hybrid chain concentration screening

[0041] (1) The gold electrode was polished in 0.3 µM and 0.05 µM alumina slurry in turn until it became a mirror surface, and then PBS buffer and ddH were used in turn. 2 O were washed 3-5 times repeatedly;

[0042](2) 10 μL solution of 2 μM H1 chain was added dropwise to the surface of the gold electrode obtained in step (1), incubated at 37 °C for 2 h, washed with PBS buffer 3 times to obtain H1 modified gold electrode; then 30 μM H2 chain was added 10 μL was added dropwise to the surface of the H1-modified gold electrode, incubated at 37 °C for 2 h, and washed three times with PBS buffer to obtain the H1-H2-modified gold electrode;

[0043] (3) Add 0 μL, 0.25 μL, 0.5 μL, 1 μL, 2 μL, and 4 μL of the Apt-T hybrid chain solution obtained in Example 1 to 1 μL of 10 nM ampicillin, 1 μL of 20 μM H3 chain solution, and 100 μM, respectively. 3 μL of H4 chain solution, add ddH 2 O supplemented to 10 μL, mixed evenly, a...

Embodiment 3

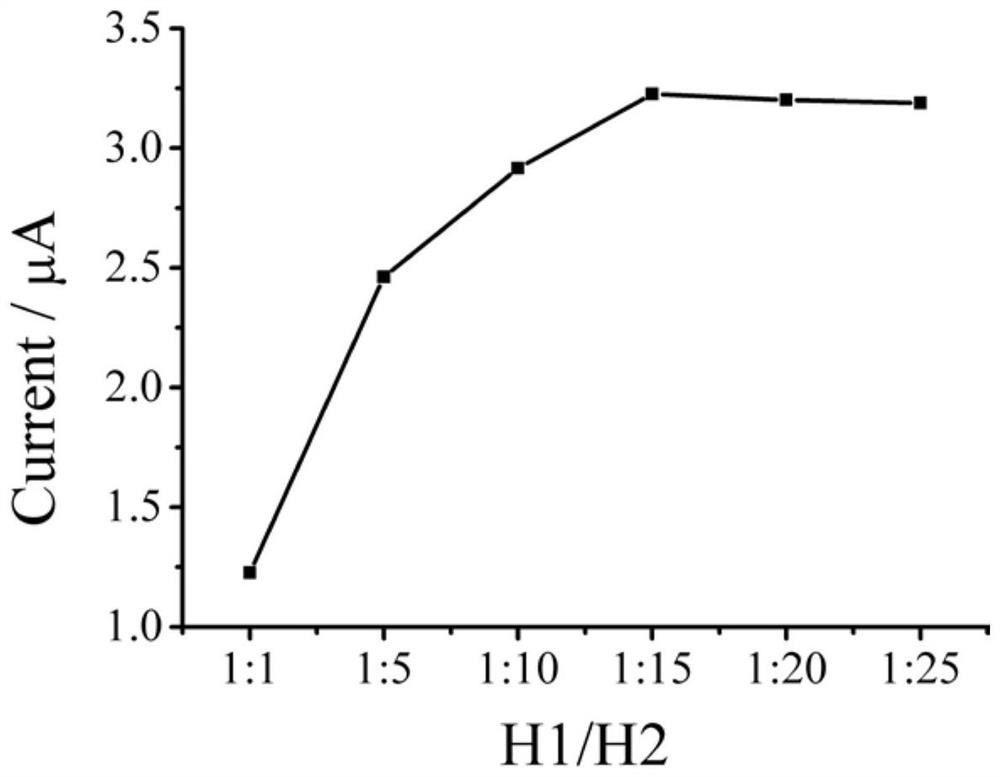

[0047] Example 3 Screening of the molar ratio of H1 chain and H2 chain

[0048] (1) The gold electrode was polished in 0.3 µM and 0.05 µM alumina slurry in turn until it became a mirror surface, and then PBS buffer and ddH were used in turn. 2 O were washed 3-5 times repeatedly;

[0049] (2) 10 μL solution of 2 μM H1 chain was added dropwise to the surface of the gold electrode obtained in step (1), incubated at 37 °C for 2 h, and washed with PBS buffer three times to obtain the H1 modified gold electrode; , 10 μM, 20 μM, 30 μM, 40 μM, and 50 μM of H2 chain 10 μL were added dropwise to the surface of the H1-modified gold electrode, incubated at 37 °C for 2 h, rinsed three times with PBS buffer to obtain H1-H2 modified gold electrode;

[0050] (3) Add 1 μL of Apt-T hybrid chain solution obtained in Example 1, 1 μL of 10 nM ampicillin, 1 μL of 20 μM H3 chain solution and 5 μL of 100 μM H4 chain solution, and add ddH 2 Add O to 10 μL, mix well, and react in a water bath at 37 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com