Preparation method of purple sweet potato and blueberry compound beverage

A beverage and blueberry technology, which is applied to the functions of food ingredients, food ingredients containing natural extracts, food ingredients as taste improvers, etc., can solve the problems of affecting storage stability, loss of beverage nutritional content, affecting flavor and taste, etc. Achieve the effects of strengthening human immunity, reducing flavor, inhibiting coagulation and/or coagulation and/or precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

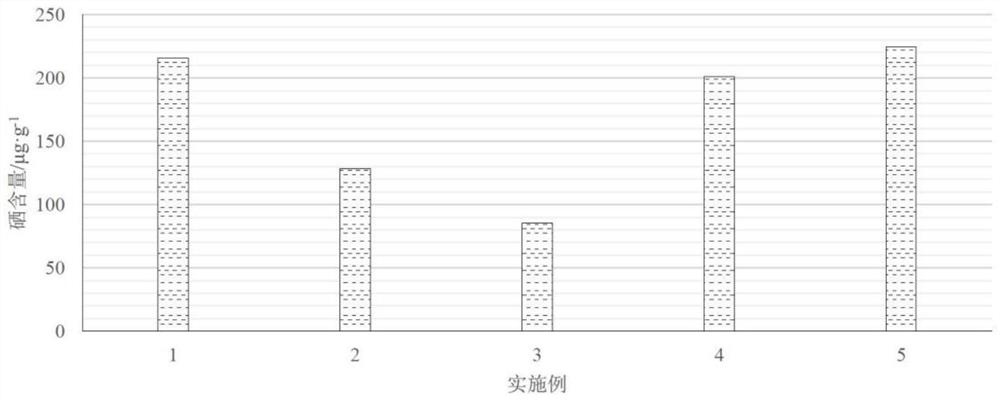

Embodiment 1

[0079] The present embodiment provides a kind of selenized corn silk polysaccharide:

[0080]Corn silk is crushed until it passes through a 100-mesh sieve, boiled with 30 times of water for 1 hour, centrifuged at 4500r / min for 30 minutes to obtain the supernatant, ultrafiltered with a 10kDa ultrafiltration membrane, and the ultrafiltration concentrate is collected and dried at 60°C until constant weight. Crude polysaccharides were ground to a 100-mesh sieve to make a 1% polysaccharide solution, added absolute ethanol until the alcohol concentration reached 50%, left to settle at 1°C for 24 hours, centrifuged at 9000r / min to obtain the supernatant, and continued to add absolute ethanol until Alcohol concentration 85%, settling at 1°C for 24h, centrifuging at 9000r / min to take the precipitate to obtain corn silk polysaccharide, dissolving in 0.2% dilute nitric acid solution until the content of corn silk polysaccharide is 6g / L, stirring at room temperature 300r / min for 1h, adding...

Embodiment 2

[0082] This embodiment provides another selenized corn silk polysaccharide:

[0083] Corn silk is crushed until it passes through a 100-mesh sieve, boiled with 30 times of water for 1 hour, centrifuged at 4500r / min for 30 minutes to obtain the supernatant, ultrafiltered with a 10kDa ultrafiltration membrane, and the ultrafiltration concentrate is collected and dried at 60°C until constant weight. Crude polysaccharide, dissolved in 0.2% dilute nitric acid solution until the corn silk polysaccharide content is 6g / L, stirred at room temperature 300r / min for 1h, added sodium selenite 1.1 times the weight of corn silk polysaccharide and calcium chloride 1.5 times, 5 ℃ / The temperature was raised to 60°C and stirred for 6 hours; after the mixture was cooled to room temperature, saturated sodium carbonate solution was added dropwise to adjust the solution to pH 7.5, and sodium sulfate 1.1 times the amount of calcium chloride was added, centrifuged at 3000r / min for 1 hour, and the sup...

Embodiment 3

[0085] This embodiment provides another selenized corn silk polysaccharide:

[0086] Corn silk is crushed until it passes through a 100-mesh sieve, boiled with 30 times of water for 1 hour, centrifuged at 4500r / min for 30 minutes to obtain the supernatant, ultrafiltered with a 10kDa ultrafiltration membrane, and the ultrafiltration concentrate is collected and dried at 60°C until constant weight. Crude polysaccharides were ground to 100 mesh sieves to form a 1% polysaccharide solution, added absolute ethanol until the alcohol concentration reached 50%, left to settle at 1°C for 24 hours, and centrifuged at 9000r / min to obtain the corn silk polysaccharides, dissolved to 0.2 % dilute nitric acid solution until the corn silk polysaccharide content is 6g / L, stir at room temperature at 300r / min for 1h, add sodium selenite 1.1 times the weight of corn silk polysaccharide and calcium chloride 1.5 times, heat up to 60°C at 5°C / min and stir React for 6 hours; after the mixture is coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com