Novel method for purifying and recycling arsenic-containing flue gas by using acidic liquid medium

A technology of liquid medium and new method, applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve the problems of reduced overall treatment effect, unsatisfactory gravity dust removal effect, and limited guiding significance of flue gas purification, etc. The effect of less heavy metal enrichment, reducing the production of polluted acid and avoiding the generation of polluted acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

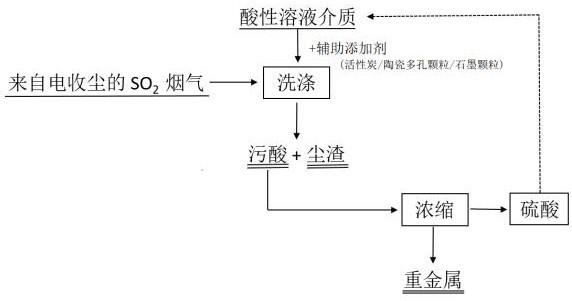

Method used

Image

Examples

Embodiment 1

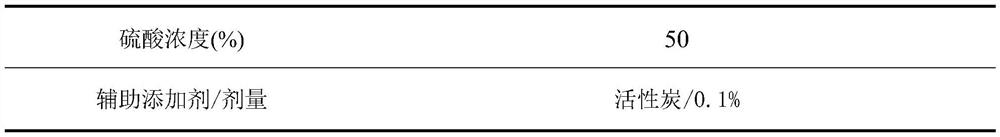

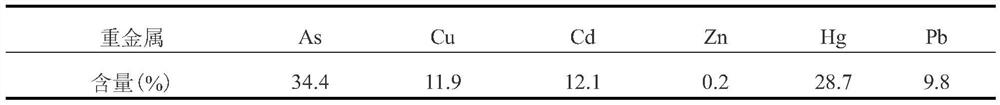

[0025]The washing solutions prepared in this embodiment are shown in Table 1.

[0026] Table 1 Washing Solution Components

[0027]

[0028] A new method for purifying arsenic-containing flue gas with an acidic liquid medium and recycling it, the specific steps are as follows:

[0029] (1) Add sulfuric acid to the flue gas washing water to prepare an acid medium solution, so that the concentration of sulfuric acid accounts for 50% of the total concentration of the washing solution.

[0030] (2) Adding an auxiliary additive with a mass ratio of 0.1% in the washing solution to enhance the washing effect; wherein the added auxiliary additive is activated carbon.

[0031] (3) Use the cold solution of the prepared washing solution to spray the flue gas (the flue gas to be deeply purified before entering the flue gas acid production), the reaction temperature is room temperature, and the flue gas is washed by countercurrent gas-liquid phase contact Purification; the flue gas pu...

Embodiment 2

[0043] The washing solutions prepared in this embodiment are shown in Table 5.

[0044] Table 5 Acidic liquid medium composition

[0045]

[0046] A new method for purifying arsenic-containing flue gas with an acidic liquid medium and recycling it, the specific steps are as follows:

[0047] (1) Add sulfuric acid to the flue gas washing water to prepare an acidic medium solution, so that the concentration of sulfuric acid accounts for 100% of the total concentration of the washing solution.

[0048] (2) Adding an auxiliary additive with a mass ratio of 1% in the washing solution to enhance the washing effect; wherein the added auxiliary additive is ceramic porous particles.

[0049] (3) Use the prepared acidic liquid medium cold solution to spray the flue gas (the flue gas to be deeply purified before entering the flue gas acid production), the reaction temperature is 350 ° C, and the flue gas is subjected to countercurrent gas-liquid contact. Washing and purification; th...

Embodiment 3

[0061] The concentration of sulfuric acid prepared in this embodiment is as shown in Table 9.

[0062] Table 9 Acidic liquid medium composition

[0063]

[0064] A new method for purifying arsenic-containing flue gas with an acidic liquid medium and recycling it, the specific steps are as follows:

[0065] (1) Add sulfuric acid to the flue gas washing water to prepare an acidic medium solution, so that the concentration of sulfuric acid accounts for 75% of the total concentration of the washing solution.

[0066] (2) Adding an auxiliary additive with a mass ratio of 0.5% in the washing solution to enhance the washing effect; wherein the added auxiliary additive is graphite particles.

[0067] (3) Use the prepared acidic liquid medium cold solution to spray the flue gas (the flue gas to be deeply purified before entering the flue gas acid production), the reaction temperature is 150 ° C, and the flue gas is subjected to countercurrent gas-liquid contact. Washing and purifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com