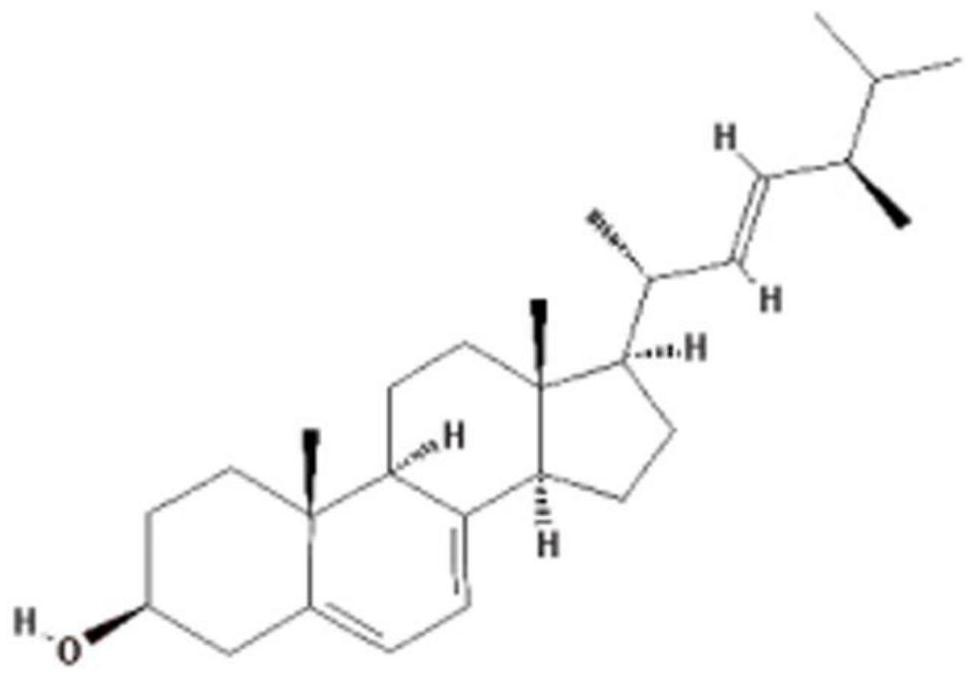

Preparation method of ergosterol

A technology of ergosterol and preparation steps, which is applied in the field of preparation of ergosterol, can solve problems such as affecting the yield and decreasing the extraction purity, and achieve the effect of increasing the extraction rate and mild production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

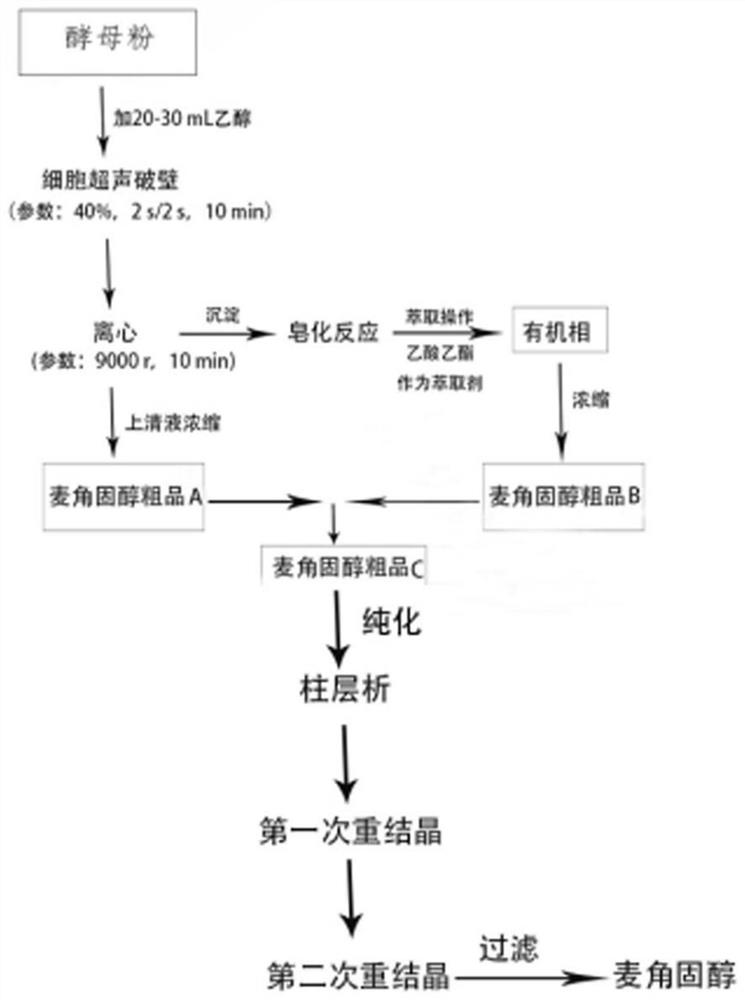

Method used

Image

Examples

Embodiment 1

[0073] 1. Ultrasonic wall breaking: Weigh 4.50 g of yeast powder and dissolve it in 20 mL of ethanol, place it in an ultrasonic cell grinder (parameters: 40%, 2s / 2s, 10 min), centrifuge (9000 r, 10 min), and take For the supernatant, the operation was repeated twice, and the supernatant was combined and concentrated to obtain ergosterol A, and the precipitate was saponified.

[0074] 2. Saponification extraction: put the above precipitate in a 250 mL eggplant-shaped bottle, add 22.5 mL 70% ethanol to it, then add 45 ml 30% NaOH, place it at 85 o In a C oil bath, react for 2.5 hrs.

[0075] 3. Extraction and concentration: after the reaction is completed, cool to 20-30 o C, add 100 mL ethyl acetate, mix well, let it stand still, take the upper layer; then add 100 ml ethyl acetate to the lower liquid, mix well, let stand, take the upper layer; then add 100 ml to the lower liquid Ethyl acetate, mix well, let stand, take the upper layer, combine the supernatant obtained by three...

Embodiment 2

[0111] The volume ratio of alcohol to alkali is 1:2, the ratio of material saponification agent (m:V) is 1:10, and the influencing factors of saponification conditions are the mass fraction of NaOH solution (A), the volume fraction of ethanol (B), and the saponification time (C), saponification temperature (D), the experimental results are shown in Table 5.

[0112] Table 5 Experimental arrangement and results of saponification conditions

[0113]

[0114] Note: A: mass fraction of NaOH solution; B: volume fraction of ethanol solution; C: saponification time; D: saponification temperature

[0115] From the experimental results of saponification conditions, RAo The saponification temperature of C can make the extraction rate of ergosterol the highest.

Embodiment 3

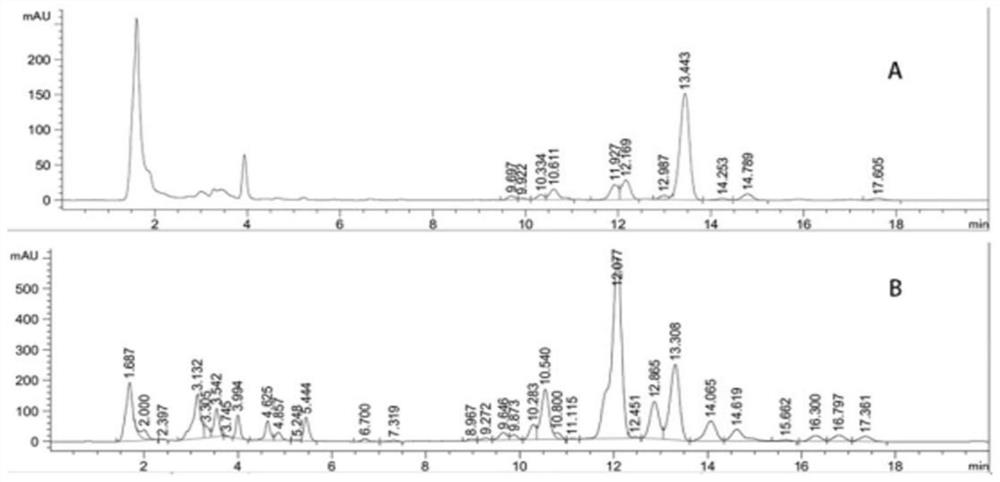

[0117] Determination of detection wavelength of ergosterol

[0118] Accurately weigh 10 mg of ergosterol standard substance in a 10 mL volumetric flask, add 3 mL of methanol to dissolve it completely, add methanol to the mark and shake well to make it a 1 mg / mL stock solution. Then precisely pipette 1 mL of the stock solution into a 10 mL volumetric flask, add methanol to the mark and shake well to obtain a 100 ug / mL sample solution. Take an appropriate amount of sample solution and blank methanol respectively in a quartz cuvette, and use a UV spectrophotometer to scan its full wavelength.

[0119] UV full-wavelength scan results (see Figure 5 ), the maximum absorption peaks appear at 270.97 nm, 281.38 nm, and 293.08 nm, and the absorption wavelength is selected as 281 nm in this paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com