(METH) acrylic resin composition and (METH) acrylic resin film

A technology based on methyl methacrylate and acrylic, applied in the field of acrylic resin film, can solve the problems of lower productivity, loss of beautiful color tone and transparency, contamination of cooling rolls, etc., and achieve an excellent effect of gel fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The method for producing the acrylic polymer is not particularly limited, and an appropriate known polymerization method such as a solution polymerization method or an emulsion polymerization method can be used. The acrylic polymer is preferably a copolymer with a weight average molecular weight greater than 100,000 and less than 1 million, more preferably a copolymer with a weight average molecular weight greater than 100,000 and less than 950,000, particularly preferably a weight average molecular weight greater than 100,000 And it is a copolymer of less than 900,000. If the weight-average molecular weight of the acrylic polymer is 100,000 or less, even if the (meth)acrylic resin composition is crosslinked, it is difficult to obtain a molded article such as a (meth)acrylic resin film having excellent physical properties. . When the weight average molecular weight of the said acrylic polymer exceeds 1 million, the solution of a (meth)acrylic resin composition will bec...

Embodiment 1

[0082] Nitrogen gas was introduced into a reaction device equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen gas introduction tube to replace the air in the reaction device with nitrogen gas. Then, 95 parts by weight of methyl methacrylate, 5 parts by weight of methyl acrylate, 3.0 parts by weight of 8-hydroxyoctyl acrylate, and a solvent (ethyl acetate) were simultaneously added to the reaction device. Thereafter, 0.1 parts by weight of azobisisobutyronitrile as a polymerization initiator was added dropwise, followed by heating to 65° C. and reacting for a predetermined time to obtain the (meth)acrylic polymer solution of Example 1. When the weight average molecular weight (Mw) of the (meth)acrylic polymer contained in this (meth)acrylic polymer solution was measured, it was 200,000. To the (meth)acrylic polymer solution of Example 1, 3.0 parts by weight of CORONATE HX (isocyanurate body of a hexamethylene diisocyanate compound) was added and mixed wit...

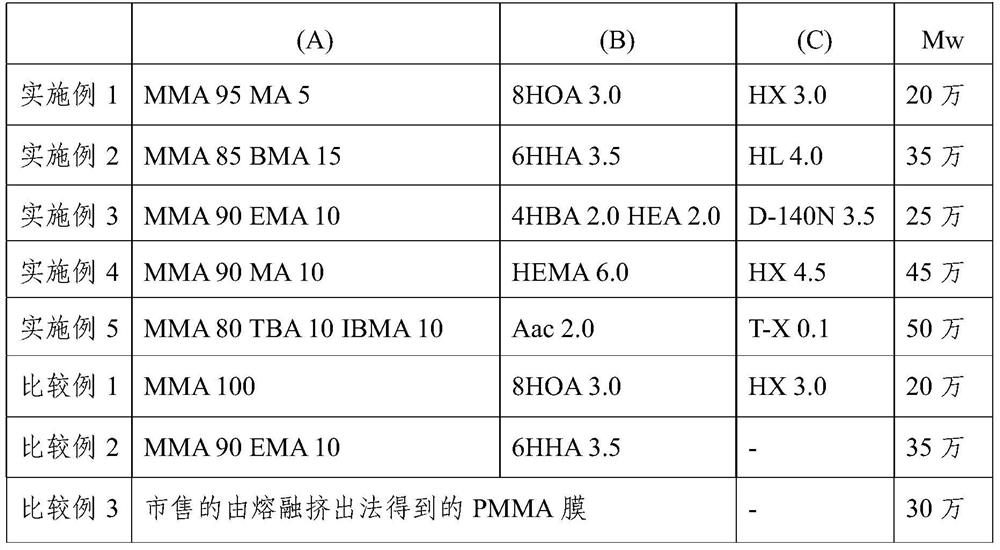

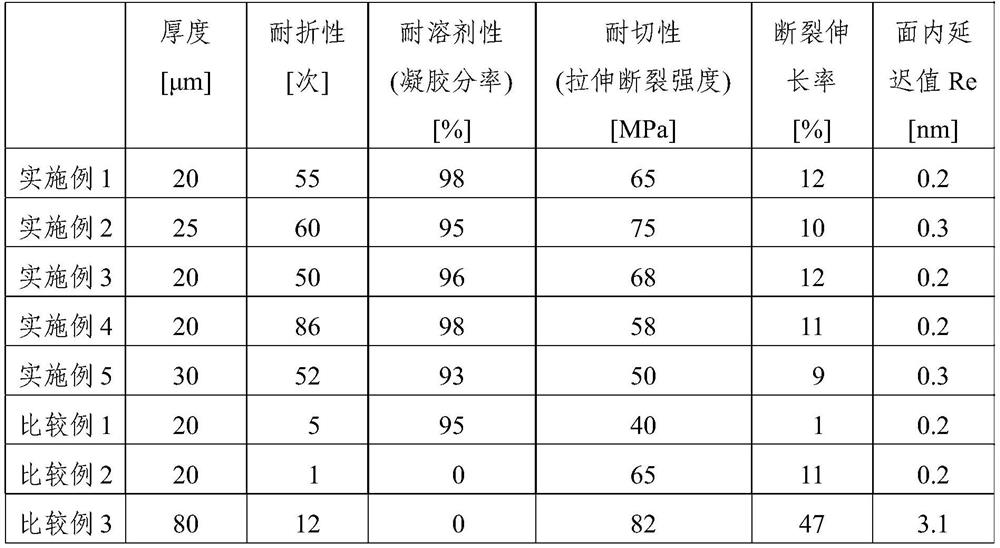

Embodiment 2~5 and comparative example 1~2

[0084] Example 1 was obtained in the same manner as in Example 1, except that the compositions of the (meth)acrylic polymer and the (meth)acrylic resin composition of Example 1 were adjusted to the compositions listed in Table 1 The (meth)acrylic polymer and (meth)acrylic resin composition of 2-5 and Comparative Examples 1-2. Table 1 shows the weight average molecular weight (Mw) of the (meth)acrylic polymer of Examples 2-5 and Comparative Examples 1-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com