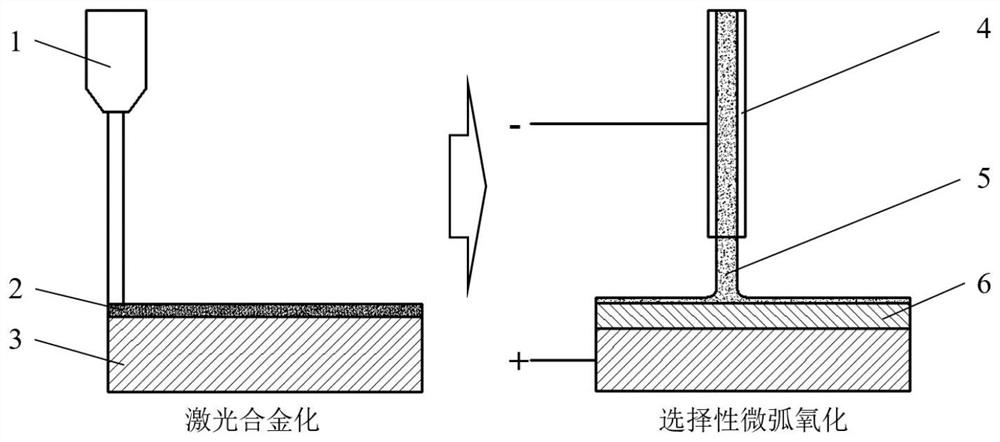

Method for preparing high-temperature-oxidation-preventing titanium alloy coating by compounding laser alloying with micro-arc oxidation

A technology of laser alloying and high temperature oxidation prevention, applied in the direction of metal material coating process, coating, anodization, etc., can solve problems such as inability to meet, and achieve the effect of improving quality, improving high temperature oxidation resistance, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Pre-treatment of titanium alloy, including grinding, cleaning and drying.

[0035] 2) Pre-place the alloy coating on the surface of the material, and control the layer thickness to 0.5mm. The alloy components in the alloy coating are: Al: 80wt.%, Si: 15wt.%, Nb: 5wt.%, and it can be carried out after it is completely air-dried Next step.

[0036] 3) Set the laser alloying process: laser power 1000W, scanning speed 1000mm / s, scanning distance 0.04mm, laser alloying treatment on the sample;

[0037] 4) Grinding the surface of the sample after laser alloying treatment to Ra 0.8 μm;

[0038] 5) Configure electrolyte: NaAlO 2 15g / L, Na 2 SiO 3 4g / L, ZrO 2 2g / L;

[0039] 6) Set the pulse power supply current density of the micro-arc oxidation process to 9A / dm 2 , The pulse frequency is 500Hz, the duty cycle is 30%, the electrode spacing is 10mm, the electrolyte flow rate is 0.5mm / s, the cathode moving speed is 3mm / min, and the film overlap rate is 40%, and the mi...

Embodiment 2

[0043] The alloy composition in the alloy paint is: Al: 50wt.%, Si: 25wt.%, Nb: 25wt.%, and the thickness of the control layer is 0.5mm.

[0044] Set the laser alloying process: laser power 1000W, scanning speed 1000mm / s, scanning distance 0.04mm.

[0045] Grind the surface of the sample after laser alloying treatment to Ra 0.8μm

[0046] Configuration electrolyte: NaAlO 2 4g / L, Na 2 SiO 3 8g / L, ZrO 2 5g / L.

[0047] Set the pulse power supply current density of micro-arc oxidation process to 9A / dm 2, The pulse frequency is 500Hz, the duty ratio is 30%, the electrode spacing is 10mm, the electrolyte flow rate is 0.5mm / s, the cathode moving speed is 3mm / min, and the film overlap rate is 40%.

[0048] Other processing steps are as embodiment 1.

[0049] The surface of the prepared coating was inspected, and the surface quality of the coating was good without defects.

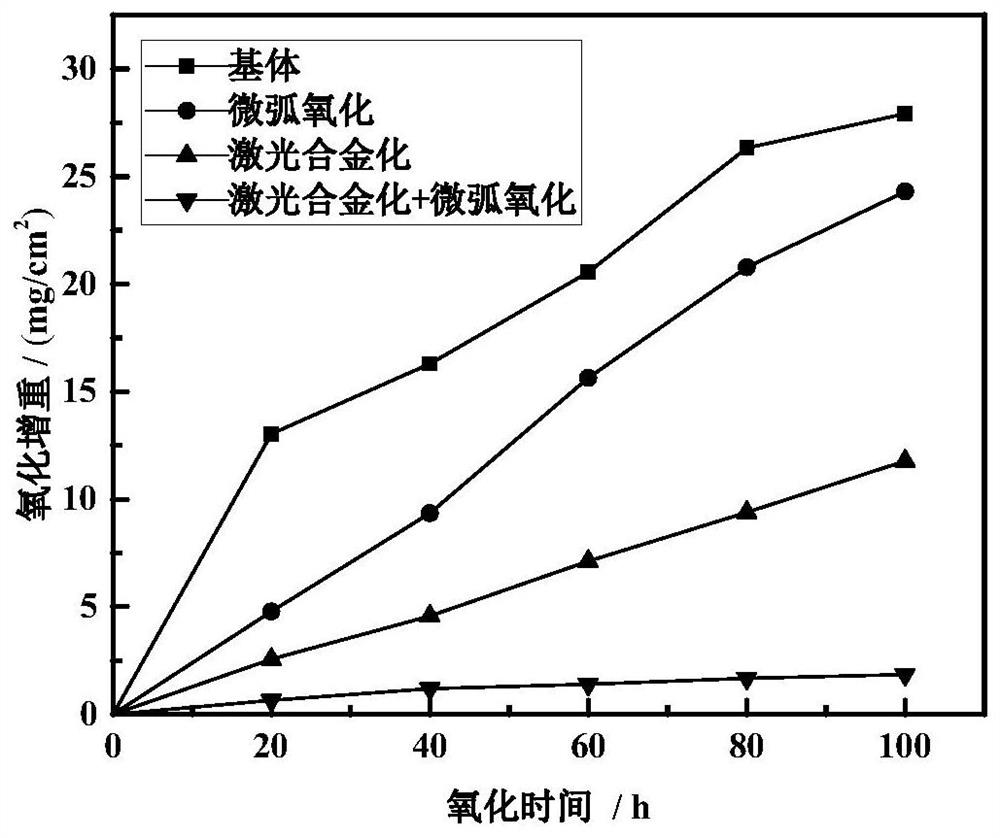

[0050] After high-temperature oxidation at 900°C for 100 hours, the substrate oxidation weight gain i...

Embodiment 3

[0052] The alloy components in the alloy paint are: Al: 80wt.%, Si: 15wt.%, Nb: 5wt.%, and the control layer thickness is 0.2.

[0053] Set the laser alloying process: laser power 500W, scanning speed 200mm / s, scanning distance 0.08mm.

[0054] Grinding the surface of the sample after laser alloying treatment to Ra 1.6μm

[0055] Configuration electrolyte: NaAlO 2 15g / L, Na 2 SiO 3 4g / L, ZrO 2 2g / L.

[0056] Set the pulse power supply current density of micro-arc oxidation process to 3A / dm 2 , The pulse frequency is 1000Hz, the duty cycle is 10%, the electrode spacing is 15mm, the electrolyte flow rate is 1.5mm / s, the cathode moving speed is 5mm / min, and the film overlap rate is 20%.

[0057] Other processing steps are as embodiment 1.

[0058] The surface of the prepared coating was inspected, and the surface quality of the coating was good without defects.

[0059] After high-temperature oxidation at 900°C for 100 hours, the substrate oxidation weight gain is 27.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxidative weight gain | aaaaa | aaaaa |

| Oxidative weight gain | aaaaa | aaaaa |

| Oxidative weight gain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com