Method and device for preparing laser-induced graphene-coated conductive glass fiber net

A laser-induced, graphene technology, applied in non-metallic conductors, textiles and papermaking, fiber raw material processing, etc., can solve the problem of inability to kill viruses and bacteria, and no killing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

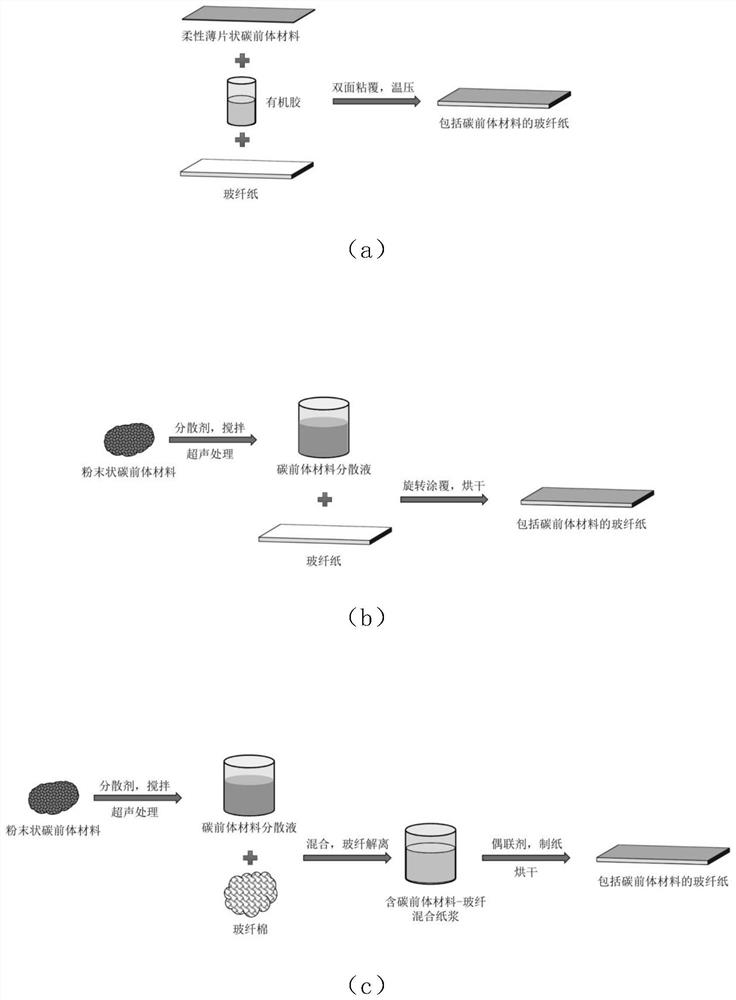

[0044] A flexible PI sheet (or film) and glass fiber paper are used as raw materials for preparing glass fiber paper including carbon precursor materials. Specifically, first cut the flexible PI sheet into the same size as the glass fiber paper, coat the flexible PI sheet with high-performance silicone pressure-sensitive adhesive, and respectively stick the flexible PI sheet on the upper and lower surfaces of the glass fiber paper, And under the condition of 180 ℃, the glass fiber paper coated with PI was prepared. For a schematic diagram of the preparation process, see figure 1 (a).

Embodiment 2

[0046] PI thermoplastic powder and glass fiber paper are used as raw materials for preparing glass fiber paper including carbon precursor materials. Specifically include:

[0047] (1) Preparation of carbon precursor material dispersion: use PI thermoplastic powder as a carbon-containing precursor material to prepare a PI thermoplastic solution, add a dispersant, and perform ultrasonic treatment to obtain a uniform PI carbon precursor material dispersion;

[0048] (2) Coating of glass fiber paper: the prepared PI carbon precursor material dispersion is uniformly coated on the surface of glass fiber paper by a spin coating method, and the coating thickness is 50-100 μm;

[0049] (3) Drying of glass fiber paper including carbon precursor material: place the glass fiber paper coated with PI carbon precursor material dispersion on a drying plate at 100°C for drying treatment to obtain single-sided coated PI Glass fiber paper of carbon precursor material;

[0050] Repeat the above...

Embodiment 3

[0052] Carbon-containing precursor materials such as PI, graphite, glucose, and glass fiber cotton are used as raw materials for preparing glass fiber paper including carbon precursor materials. Specifically include:

[0053] (1) Preparation of carbon precursor material dispersion: use various carbon-containing precursor materials including PI thermoplastic powder, graphite, glucose, etc. to prepare a solution, add a dispersant, and perform ultrasonic treatment to obtain a variety of uniform carbon-containing a dispersion of precursor material;

[0054] (2) Carbon-containing precursor material-glass fiber mixed pulp: fully soak the ultra-fine glass fiber cotton in the carbon precursor material dispersion, and break up the glass fiber cotton through a fiber dissociator to prepare a carbon-containing precursor material- Glass fiber pulp suspension;

[0055] (3) Preparation of glass fiber paper including carbon precursor material: the carbon precursor material-glass fiber mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com