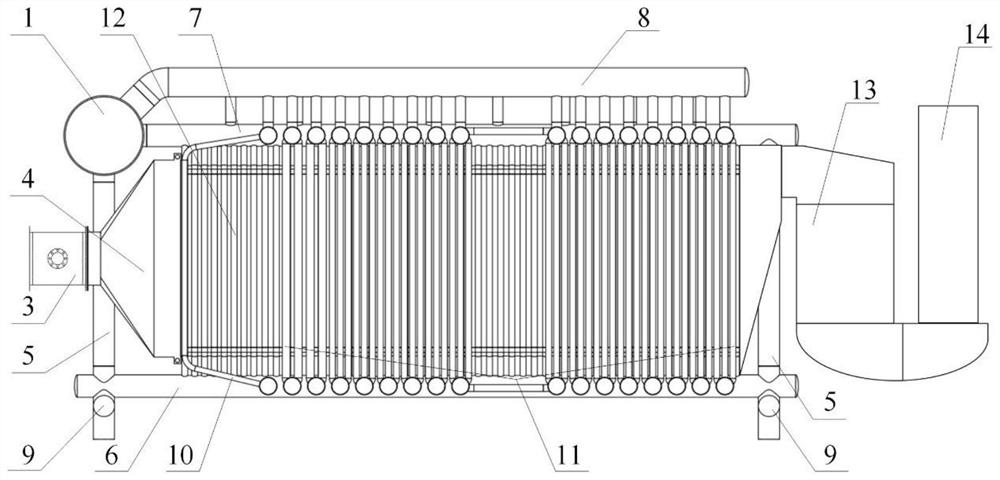

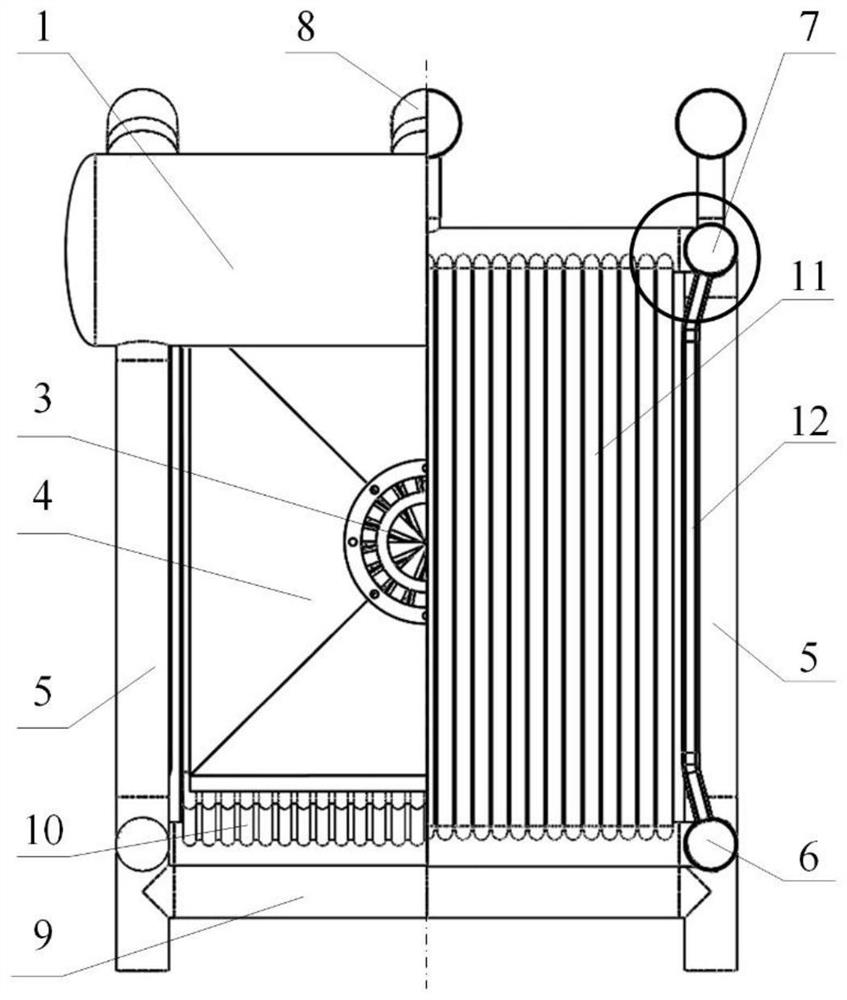

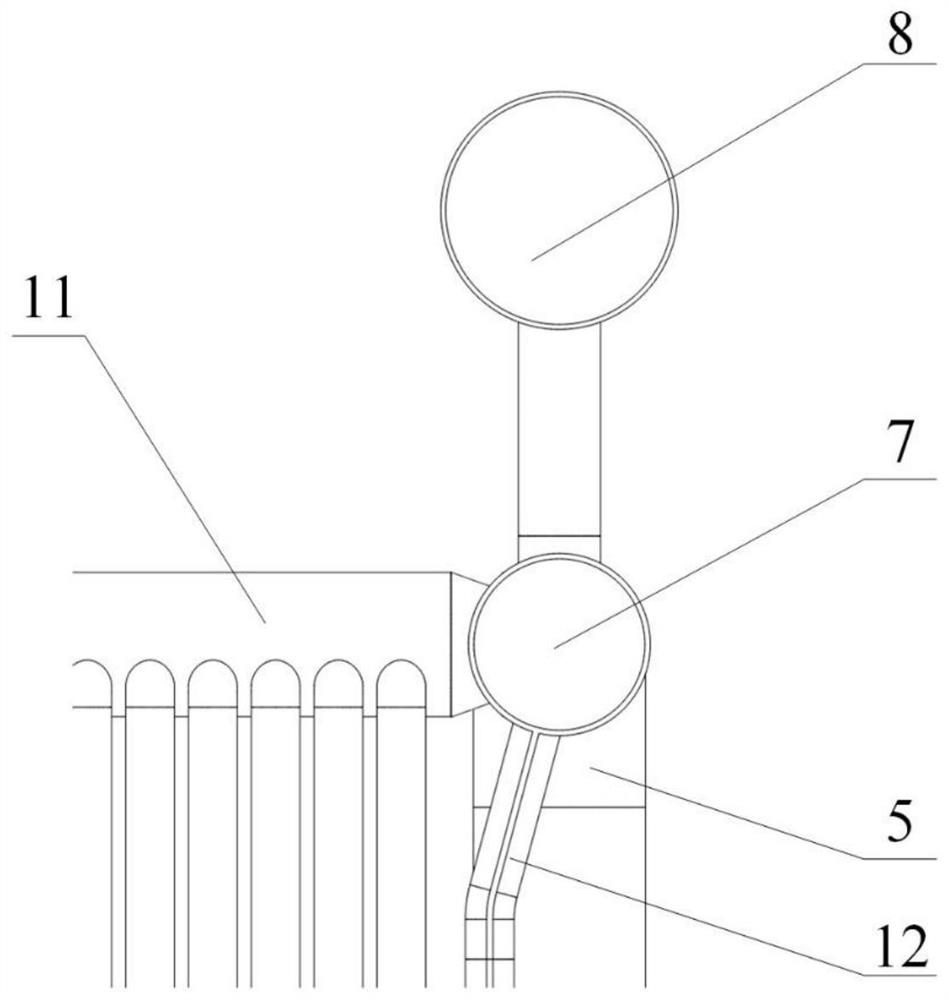

Premixed water-cooed combustion corner tube steam boiler

A steam boiler and water-cooling technology, which is applied to steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of limited boiler stability and seismic performance, inability to realize large-scale, limited pressure of tube sheet structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Corner tube boilers, as a fully developed form of water tube boilers, are used in various large-capacity pressure-bearing boilers. The frame structure composed of corner tubes is self-supporting and can be used as the overall support frame of the boiler, so that the boiler does not need to add a steel frame structure, which improves the overall structural stability and seismic performance of the boiler. The corner tube forms an independent downcomer at the front and back of the boiler. When the downcomer and the flue gas circulation area are separated by insulation materials, the downflow inside it will not be affected by heat, so the overall water circulation of the boiler has good characteristics, so that the boiler only needs to be set One drum, and more tube bundles can be set from front to back along the flue gas flow direction. It is well adaptable to the small furnace space. A combination of planar burners and corner tube boilers can be designed to achieve low-nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com