Organic zinc compounded oil-control anti-dandruff shampoo and preparation method thereof

A technology of shampoo and organic zinc, which is applied in the field of organic zinc compound oil control and antidandruff shampoo, can solve the problems of easy generation of drug resistance, poor effect sustainability, poor oil control effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] (1) 54.04 parts of water, 15 parts of sodium laureth sulfate and 2 parts of sodium lauryl sulfate are used as phase A for subsequent use;

[0067] Mix 1 part of Cocamide MEA, 1 part of Ethylene Glycol Distearate, 0.3 part of Cetearyl Alcohol, 4 parts of Cocamidopropyl Betaine, 1 part of Alkyl Glucoside and Cocoyl Glutamic Acid 4 parts of disodium are used as phase B for later use;

[0068] Use 4 parts of water and 0.3 part of guar gum hydroxypropyltrimethylammonium chloride as phase C for later use;

[0069] 4 parts of water, 0.1 parts of zinc sulfate, 0 parts of zinc lactate, 0 parts of zinc pyrithione, and 0 parts of yeast zinc are used as phase D for later use;

[0070] Use 2.5 parts of polydimethylsiloxane emulsion, 0.5 parts of essence, 0.1 part of menthol, 0.06 parts of kathone, and 0.6 parts of phenoxyethanol as phase E for later use;

[0071] 2 parts of water and 1.5 parts of acrylic acid (ester) copolymer are used as the F phase for subsequent use;

[0072] ...

Embodiment 2-9

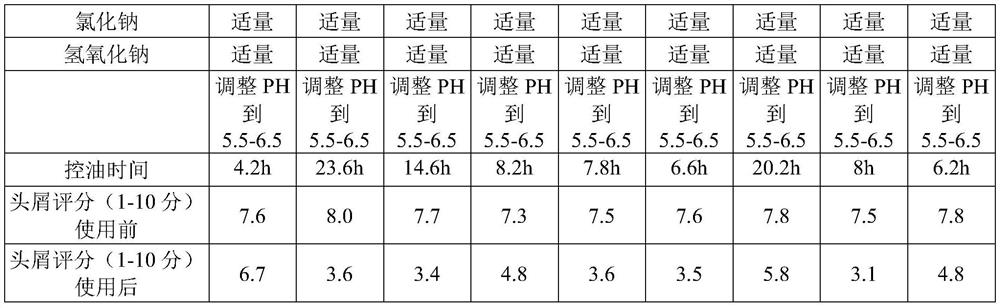

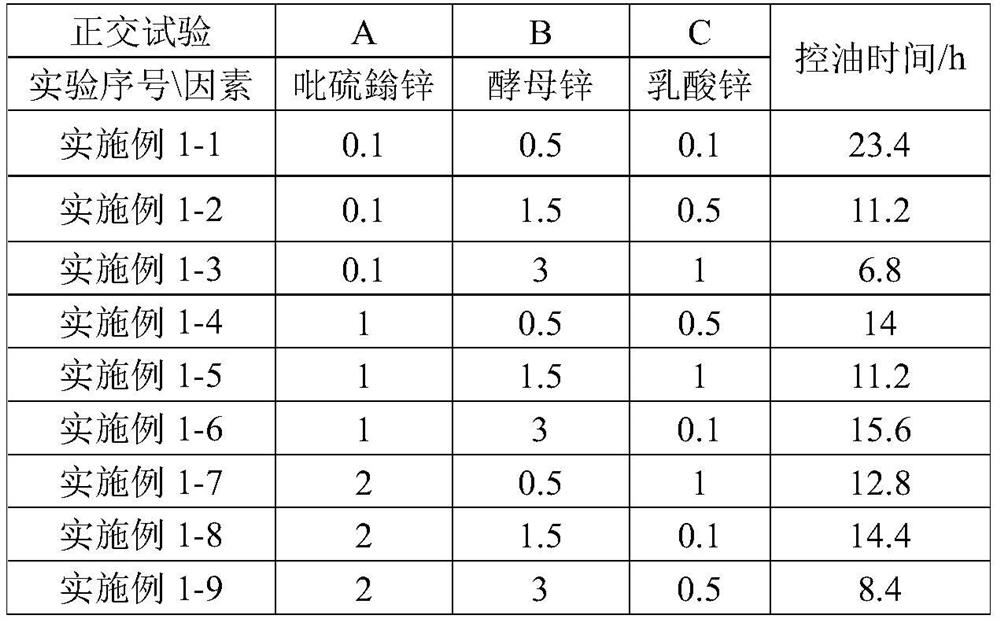

[0080] Embodiments 2-9 change a certain experimental parameter, other operation steps and testing process are the same as embodiment 1, and the specific setting method is shown in Table 1.

[0081] Table 1

[0082]

[0083]

[0084] Shampoo Oil Control Ability Test

[0085] 90 volunteers were recruited as subjects, aged between 20 and 40 years old. All the volunteers were divided into 9 groups, 10 people in each group, and each group used the shampoos prepared in Examples 1-9. The subjects did not wash their hair 24 hours before the test, and the baseline value was tested. After washing hair with the shampoo corresponding to each embodiment on the spot, measure the oil value of the scalp (top of the head) at T0 instant, T2h, T4h, T6h, T8h, T20h, T24h and T26h respectively, and then take the oil control time of each group of subjects as Average number, obtain the oil control time for each embodiment.

[0086] A randomized, parallel controlled study was used to measur...

Embodiment 1

[0107] (1) 5 parts of water and 0.32 parts of guar gum hydroxypropyltrimethylammonium chloride are used as phase A for subsequent use;

[0108] 34.48 parts of water, 20 parts of disodium cocoyl glutamate, 16 parts of cocamidopropyl betaine, 5 parts of alkyl glucoside and 5 parts of sodium methyl cocoyl taurate are used as phase B for later use;

[0109] 1 part of ethylene glycol distearate, 0.4 part of glycerin laurate, 0.5 part of butylene glycol laurate, 1.5 parts of cocamide methyl MEA, 0.5 part of PPG-3 octyl ether and isostearyl alcohol 0.4 part of pivalic acid ester is standby as C phase;

[0110] 5 parts of water, 0.1 part of zinc sulfate, 0 part of zinc lactate, 0 part of pyrithione zinc and 0 part of yeast zinc are used as phase D for standby;

[0111] Use 0.6 parts of essence, 0.8 parts of phenoxyethanol and 0.4 parts of sodium benzoate as phase E for later use;

[0112] Use 1 part of citric acid and 1 part of water as phase F for later use;

[0113] (2) Clean the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com