Method for enhancing shale carbon dioxide adsorption performance and cooperatively storing nitrogen dioxide

A nitrogen dioxide and carbon dioxide technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of small adsorption capacity of adsorbents, large adsorbents, and decreased thermal efficiency of boilers, and achieve enhanced storage performance and greenhouse gas. The effect of alleviating the effect and enhancing the adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

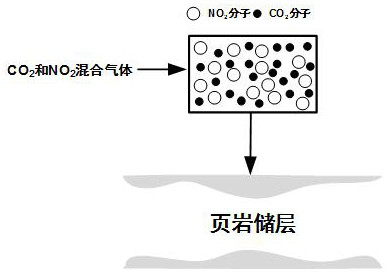

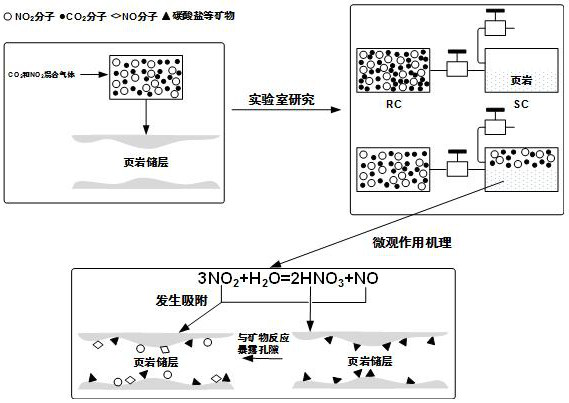

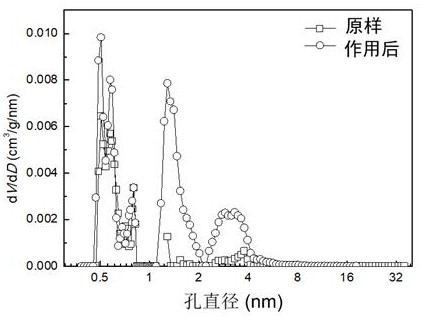

[0034] Embodiment 1: as figure 2 As shown, the present embodiment utilizes nitrogen dioxide to strengthen the carbon dioxide adsorption performance of shale and the method for synergistically sequestering nitrogen dioxide, which specifically includes the following steps:

[0035] (1) Select shale samples of different maturity to prepare water-balanced shale samples;

[0036] (2) Place the water-balanced shale sample in the pressure-resistant sample cylinder (denoted as SC) of the volumetric adsorption device;

[0037] (3) Under the conditions of adsorption temperature of 80 °C and adsorption equilibrium pressure of 30 MPa, the adsorption capacity of shale samples to pure carbon dioxide was determined by the principle of volumetric method;

[0038] (4) Inject nitrogen dioxide and carbon dioxide into the pressure-resistant reference cylinder (denoted as RC) of the volumetric adsorption device at the same time at a molar ratio of 1:100 to obtain a uniformly mixed mixture of nit...

Embodiment 2

[0042] Embodiment 2: In this embodiment, the method of using nitrogen dioxide to enhance the carbon dioxide adsorption performance of shale and synergistically store nitrogen dioxide includes the following steps:

[0043] (1) Select shale samples of different maturity to prepare water-balanced shale samples;

[0044] (2) Place the water-balanced shale sample in the pressure-resistant sample cylinder (denoted as SC) of the volumetric adsorption device;

[0045] (3) Under the conditions of adsorption temperature of 70 °C and adsorption equilibrium pressure of 25 MPa, the adsorption capacity of shale samples to pure carbon dioxide was determined by the principle of volumetric method;

[0046] (4) Simultaneously inject nitrogen dioxide and carbon dioxide into the pressure-resistant reference cylinder (denoted as RC) of the volumetric adsorption device at a molar ratio of 2:100 to obtain a uniformly mixed mixture of nitrogen dioxide and carbon dioxide. After the reference cylinder...

Embodiment 3

[0050] Embodiment 3: In this embodiment, the method of using nitrogen dioxide to enhance the carbon dioxide adsorption performance of shale and synergistically store nitrogen dioxide includes the following steps:

[0051] (1) Select shale samples of different maturity to prepare water-balanced shale samples;

[0052] (2) Place the water-balanced shale sample in the pressure-resistant sample cylinder (denoted as SC) of the volumetric adsorption device;

[0053] (3) Under the conditions of adsorption temperature of 60°C and adsorption equilibrium pressure of 20 MPa, the adsorption capacity of shale samples to pure carbon dioxide was determined by the principle of volumetric method;

[0054] (4) Simultaneously inject nitrogen dioxide and carbon dioxide into the pressure-resistant reference cylinder (denoted as RC) of the volumetric adsorption device at a molar ratio of 4:100 to obtain a uniformly mixed mixture of nitrogen dioxide and carbon dioxide; After the reference cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com