Synthesis of dicyandiamide modified palladium nano-catalyst and application of dicyandiamide modified palladium nano-catalyst in catalyzing semi-hydrogenation of phenylacetylene

A dicyandiamide and palladium nanotechnology, which is applied in the synthesis field of palladium nanocatalyst, can solve the problems of unclear active center site, complicated reaction, poor selectivity, etc., and achieve the effects of improving selectivity, simple synthesis and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

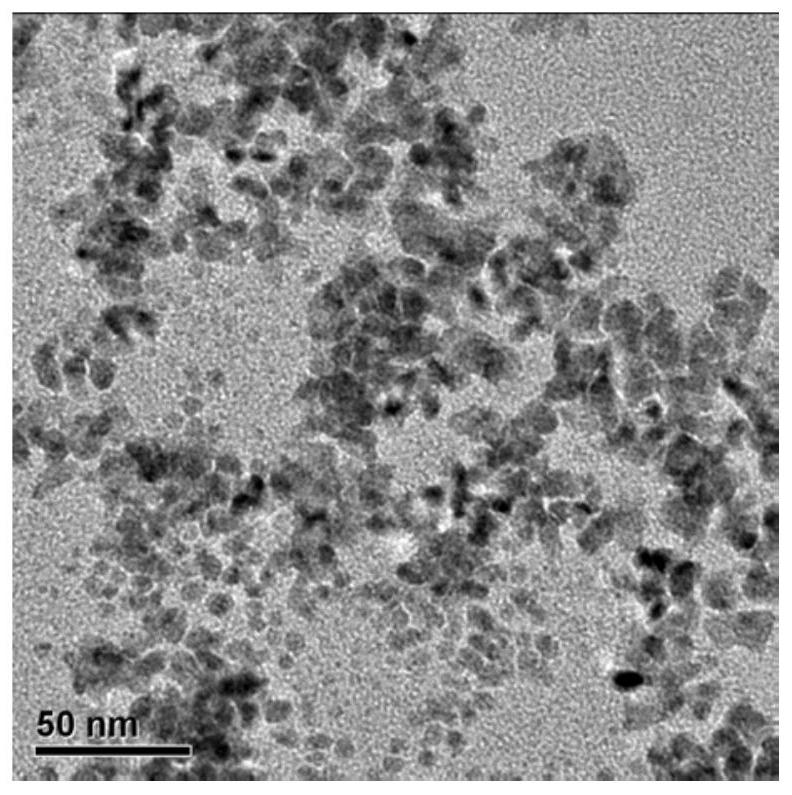

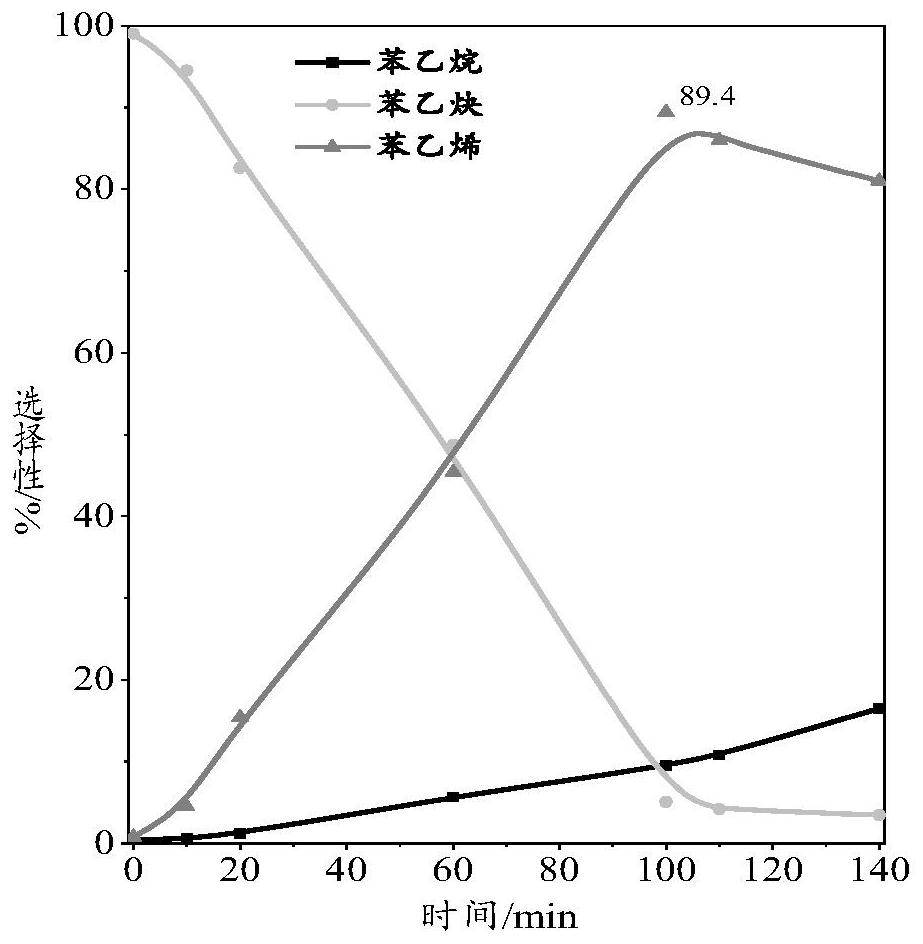

[0023] A kind of synthetic method and application of the palladium nano-catalyst modified by dicyandiamide

[0024] 1) Prepare 0.2 mol / L sodium tetrachloropalladate solution: Dissolve 1 g palladium chloride and 0.6592 g sodium chloride in 32 ml ultrapure water on an electronic balance with weighing paper to obtain 0.2 mol / L tetrachloropalladate solution Sodium chloropalladate solution, stored in the refrigerator for later use.

[0025] 2) Reduction of Pd particles: Use a manual pipette to take 30 mg sodium tetrachloropalladate solution, use a pipette to take 20 ml N,N dimethylformamide, use an electronic balance to weigh 100 mg polyvinylpyrrolidone and 200 mg sodium formate , Add the above raw materials into a thick-walled pressure-resistant bottle, ultrasonically mix for 10-20 minutes to aid in dispersion, then place it in an oil bath, set the temperature of the oil bath at room temperature to 160°C, keep it warm for 80 minutes, and then cool to room temperature. Then add et...

Embodiment 2

[0030] A kind of synthetic method of the palladium nano-catalyst modified by dicyandiamide

[0031] 1) Prepare 0.2 mol / L sodium tetrachloropalladate solution: same as Example 1.

[0032] 2) Reduction of Pd particles: Take 30 mg of sodium tetrachloropalladate solution, 20 ml of N,N dimethylformamide, 100 mg of polyvinylpyrrolidone, and 250 mg of sodium formate, add the above materials into a thick-walled pressure-resistant bottle, and ultrasonically mix for 10 minutes to help Disperse, then place in an oil bath, set the temperature of the oil bath at room temperature to 100°C, keep it warm for 240min, and then cool to room temperature. Then add ethanol and acetone and go through 3 times of centrifugation and purification to separate the Pd nanoparticles, and then dissolve them with 9mL N,N dimethylformamide to obtain a Pd nanoparticle solution;

[0033] 3) Preparation of dicyandiamide-modified Pd nanocatalyst: Take 3mL of Pd nanoparticle solution, add 720mg of dicyandiamide an...

Embodiment 3

[0035] A kind of synthetic method of the palladium nano-catalyst modified by dicyandiamide

[0036] 1) Prepare 0.2 mol / L sodium tetrachloropalladate solution: same as Example 1.

[0037]2) Reduction of Pd particles: Take 30 mg of sodium tetrachloropalladate solution, 20 ml of N,N dimethylformamide, 100 mg of polyvinylpyrrolidone, and 200 mg of sodium formate, add the above materials into a thick-walled pressure-resistant bottle, and ultrasonically mix for 20 minutes to help Disperse, then place in an oil bath, set the temperature of the oil bath at room temperature to 160°C, keep it warm for 80 minutes, and then cool to room temperature. Then add ethanol and acetone to undergo 4 times of centrifugation and purification to separate the Pd nanoparticles, and then dissolve them with 9mL N,N dimethylformamide to obtain a Pd nanoparticle solution;

[0038] 3) Preparation of dicyandiamide-modified Pd nanocatalyst: Take 3mL of Pd nanoparticle solution, add 700mg of dicyandiamide and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com