A method for synergistic treatment of wastewater with single atomic fluid heating and cooling

A co-processing, atomic technology, applied in chemical instruments and methods, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low catalyst stability, high cost of membrane separation, and inability to popularize and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

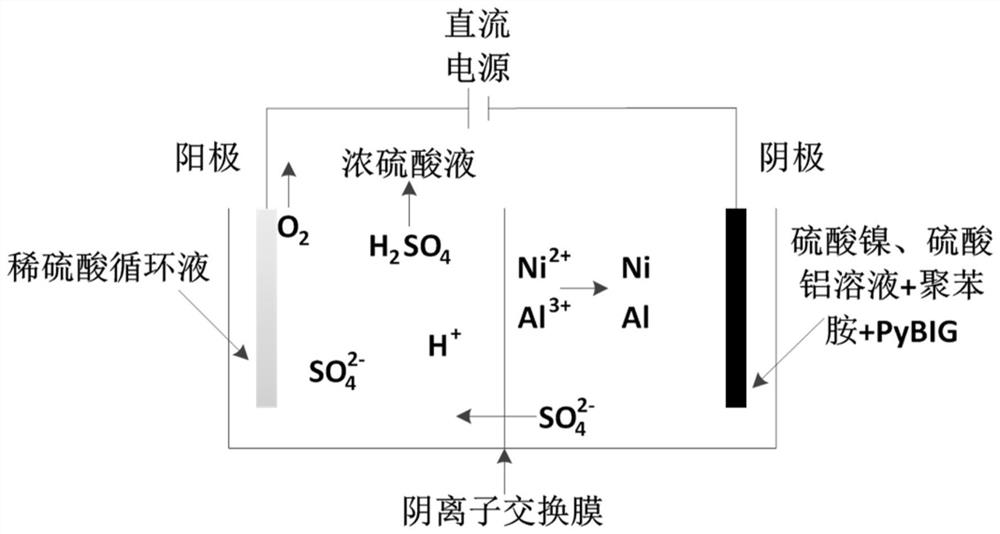

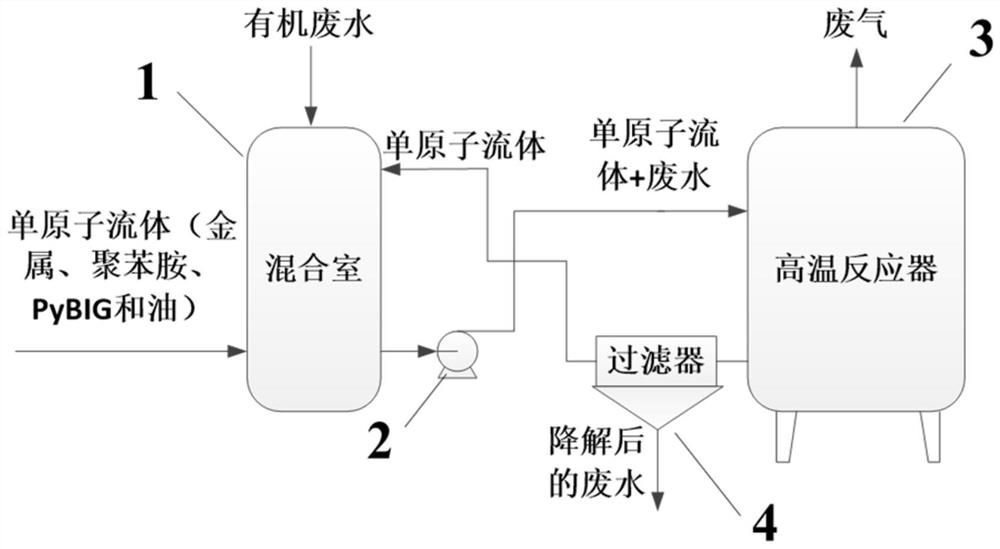

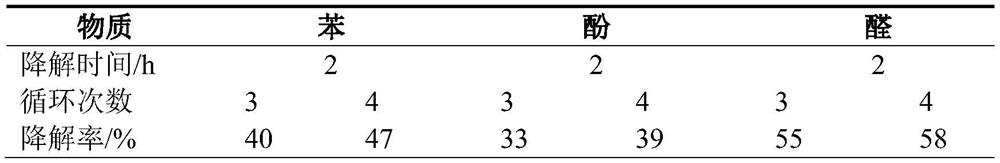

[0032] Mix metal salt solution, polyaniline and PyBIG, convert ions into atoms by electrochemical method, and then use oil extraction and filtration to obtain monoatomic fluid. The specific process is: prepare 4L each of catholyte and anolyte, and the area of anion exchange membrane is 400cm 2 , the current density is 450A / m 2 , the temperature of the electrolysis process is 50°C, and the catholyte is NiSO 4 , Al 2 (SO 4 ) 3 solution + polyaniline + PyBIG, the anolyte is dilute sulfuric acid solution. Determination of initial Ni 2+ and Al 3+ Concentrations are 0.25mol / L and 1mol / L respectively, the volume fraction of dilute sulfuric acid in the anode compartment is 0.5%, the mass of polyaniline is 130g, the mass of PyBIG is 180g, and the Ni in the solution after electrolysis for 4h 2+ and Al 3+ The concentrations are 0.17mol / L and 0.62mol / L, respectively. After the electrolysis, the solution in the cathode chamber was extracted with oil, and the quality of the oil w...

Embodiment 2

[0044] Mix metal salt solution, polyaniline and PyBIG, convert ions into atoms by electrochemical method, and then use oil extraction and filtration to obtain monoatomic fluid. The specific process is: prepare 4L each of catholyte and anolyte, and the area of anion exchange membrane is 400cm 2 , the current density is 450A / m 2 , the temperature of the electrolysis process is 50°C, and the catholyte is NiSO 4 , Al 2 (SO 4 ) 3 solution + polyaniline + PyBIG, the anolyte is dilute sulfuric acid solution. Determination of initial Ni 2+ and Al 3+ Concentrations are 0.25mol / L and 1mol / L respectively, the volume fraction of dilute sulfuric acid in the anode compartment is 0.5%, the mass of polyaniline is 130g, the mass of PyBIG is 180g, and the Ni in the solution after electrolysis for 4h 2+ and Al 3+ The concentrations are 0.17mol / L and 0.62mol / L, respectively. After the electrolysis, the solution in the cathode chamber was extracted with oil, and the quality of the oil w...

Embodiment 3

[0058] Mix metal salt solution, polyaniline and PyBIG, convert ions into atoms by electrochemical method, and then use oil extraction and filtration to obtain monoatomic fluid. The specific process is:

[0059] Prepare 4L each of catholyte and anolyte, and the area of anion exchange membrane is 400cm 2 , the current density is 450A / m 2 , the temperature of the electrolysis process is 50°C, and the catholyte contains NiSO 4 、Al 2 (SO 4 ) 3 solution, a mixture of polyaniline and PyBIG, and the anolyte is dilute sulfuric acid solution. Determination of Ni in the initial mixture 2+ and Al 3+ Concentrations are 0.25mol / L and 1mol / L respectively, the volume fraction of dilute sulfuric acid in the anode compartment is 0.5%, the mass of polyaniline is 130g, the mass of PyBIG is 180g, and the Ni in the solution after electrolysis for 4h 2+ and Al 3+ The concentrations are 0.17mol / L and 0.62mol / L, respectively. After the electrolysis, the solution in the cathode chamber was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com