A graphitized carbon material with a three-dimensional micro-nano composite structure, its preparation method and application

A micro-nano composite structure, graphitized carbon technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as unfavorable large-scale production, large changes in sulfur volume, loss of active materials, etc., to improve battery rate performance , more voids, the effect of improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

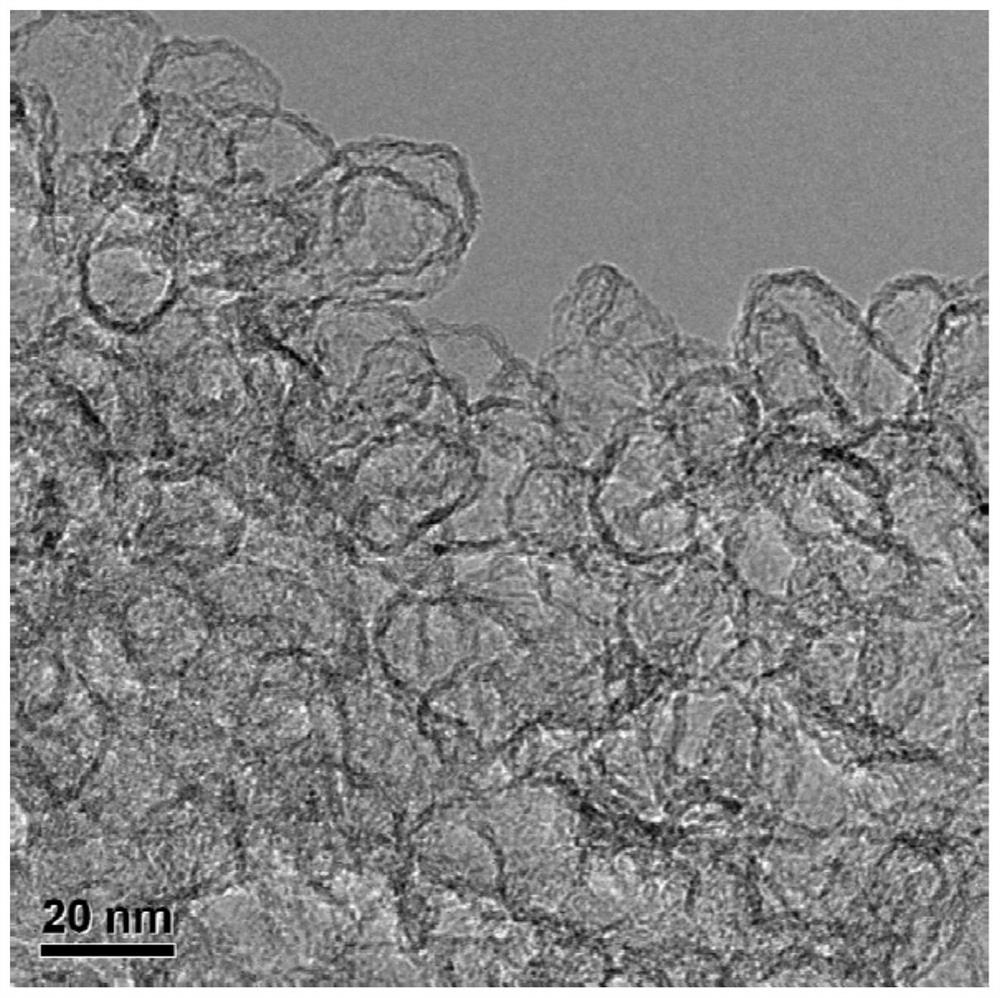

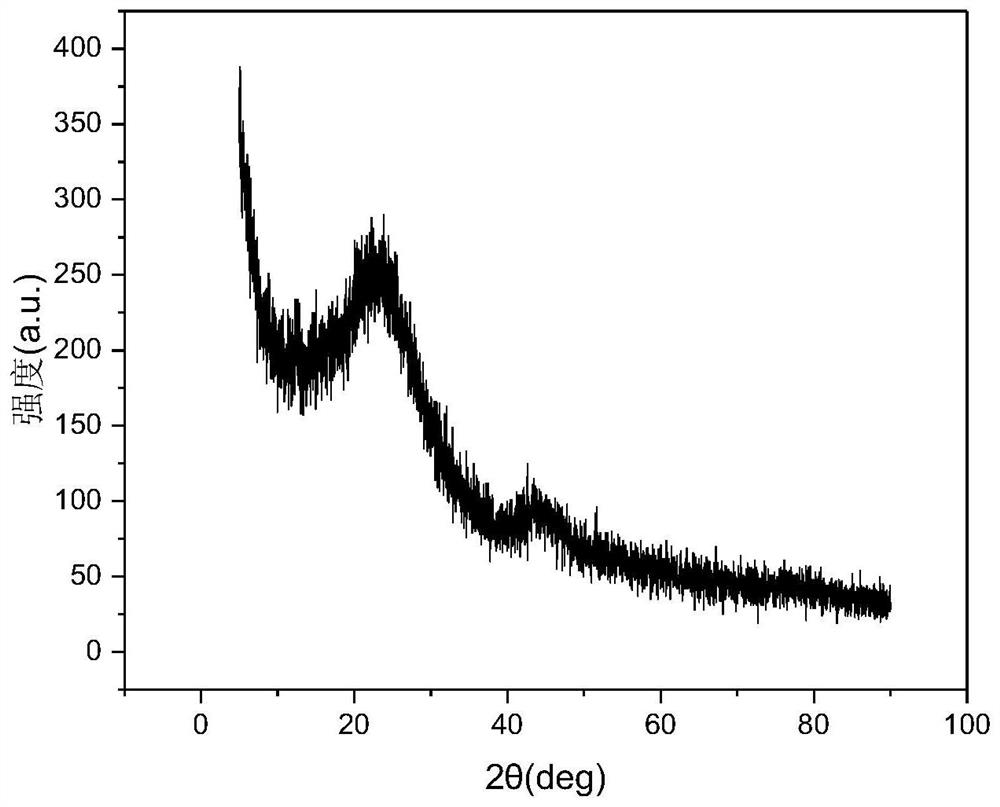

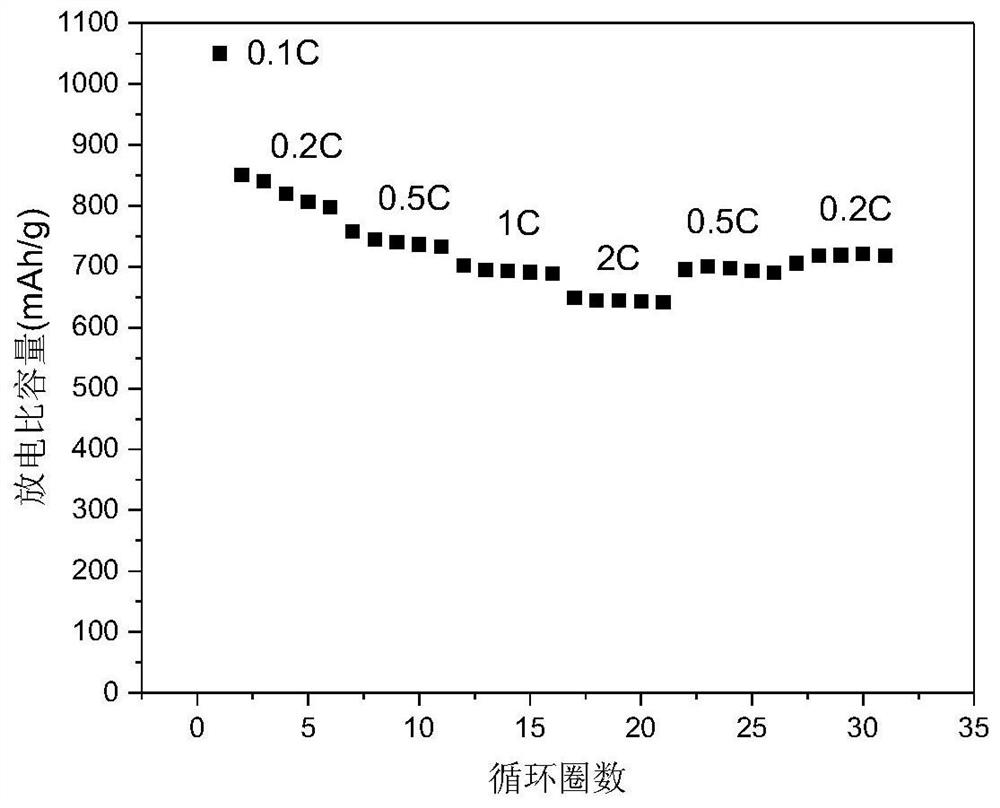

[0068] This embodiment provides a graphitized carbon material with a three-dimensional micro-nano composite structure and its preparation method

[0069] A method for preparing a graphitized carbon material with a three-dimensional micro-nano composite structure, comprising the steps of:

[0070] S1. Take 1mol of indium nitrate hydrate and 1mol of BTC, dissolve them in 80mL of DMF, stir mechanically at room temperature until the solid dissolves, transfer the mixed solution to a reaction kettle and seal it, and put the reaction kettle in an oven for reaction at 150°C The reaction was carried out for 12 hours. After the reaction was finished, it was naturally cooled to room temperature, and the reaction products were centrifugally washed three times with DMF, then three times with ethanol, and dried in an oven for 24 hours to obtain a precursor;

[0071] S2. Place the prepared precursor in a porcelain boat, and conduct carbonization treatment under the protection of an atmosphe...

Embodiment 2

[0076] This embodiment provides a graphitized carbon material with a three-dimensional micro-nano composite structure and its preparation method

[0077] A method for preparing a graphitized carbon material with a three-dimensional micro-nano composite structure, comprising the steps of:

[0078] S1. Take 1mol of indium nitrate hydrate and 1mol of BTC, dissolve them in 80mL of DMF, stir mechanically at room temperature until the solid dissolves, transfer the mixed solution to a reaction kettle and seal it, and put the reaction kettle in an oven for reaction at 150°C The reaction was carried out for 12 hours. After the reaction was finished, it was naturally cooled to room temperature, and the reaction products were centrifugally washed three times with DMF, then three times with ethanol, and dried in an oven for 24 hours to obtain a precursor;

[0079] S2. Place the prepared precursor in a porcelain boat, and conduct carbonization treatment under the protection of an atmosphe...

Embodiment 3

[0084] This embodiment provides a graphitized carbon material with a three-dimensional micro-nano composite structure and its preparation method

[0085] A method for preparing a graphitized carbon material with a three-dimensional micro-nano composite structure, comprising the steps of:

[0086] S1. Take 1.5mol indium nitrate hydrate, 1mol BTC, dissolve it in 80mL DMF, stir mechanically at room temperature until the solid dissolves, transfer the mixed solution to the reaction kettle and seal it, and put the reaction kettle in an oven for reaction, 150 °C for 12 hours. After the reaction was finished, it was naturally cooled to room temperature, and the reaction products were centrifugally washed three times with DMF, then three times with ethanol, and dried in an oven for 24 hours to obtain a precursor;

[0087] S2. Place the prepared precursor in a porcelain boat, and conduct carbonization treatment under the protection of an atmosphere of inert gas argon, at 2°C·min -1 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com