Composite remediation agent for groundwater remediation and preparation method and application thereof

A groundwater remediation and composite remediation technology, which is applied in the treatment of polluted groundwater/leachate, chemical instruments and methods, water/sewage treatment, etc. Long, high release efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

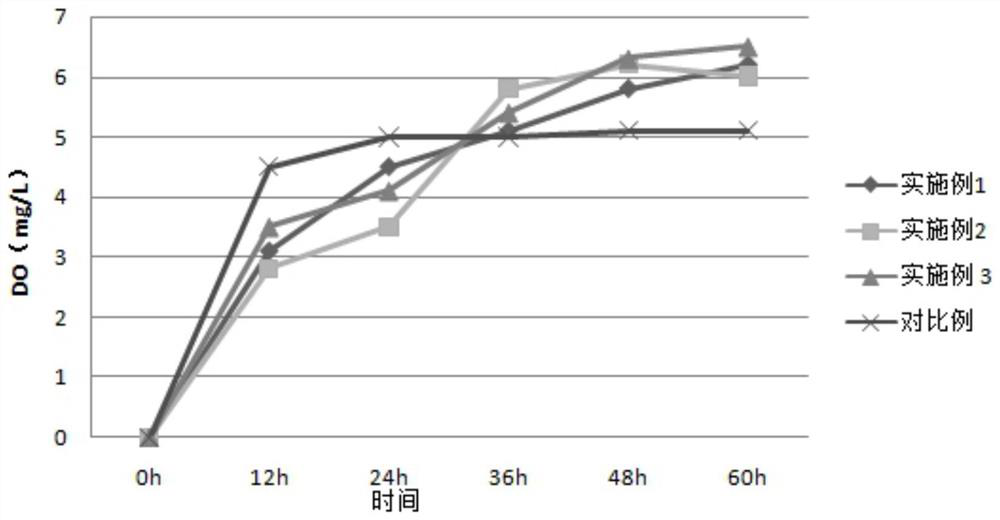

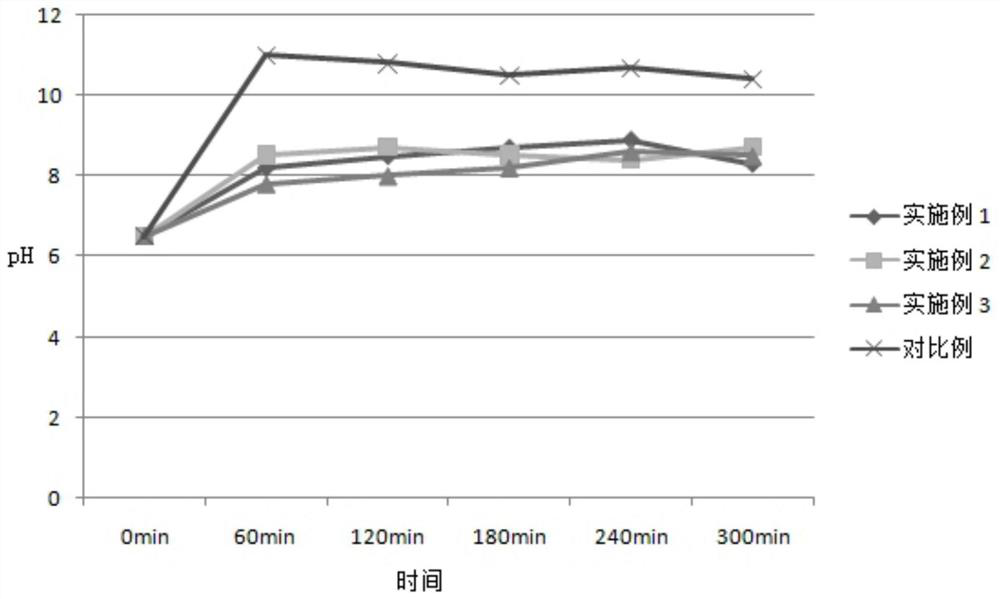

Embodiment 1

[0025] The composite restoration agent for groundwater restoration is made of the following substances in parts by mass: 22 parts of slag, 28 parts of oxygen release agent, 7 parts of Portland cement, 13 parts of filler, 18 parts of carbonized sludge, modified nano-zero price 5 parts of iron, 28 parts of pH buffer.

[0026] The oxygen release agent is calcium peroxide.

[0027] The filler is calcium-based bentonite.

[0028] The Portland cement is ordinary Portland cement.

[0029] The pH buffering agent is fly ash.

[0030] The preparation method of the composite restoration agent for groundwater restoration comprises the following steps:

[0031] (1) The gasification slag is burned at a high temperature of 900°C-1250°C, expands, is crushed after cooling, and is sieved to obtain slag particles with a particle size of 100 mesh;

[0032] (2) The air-dried sludge of domestic sewage treatment plant has a moisture content of less than 10%, then crushed and passed through an 80...

Embodiment 2

[0037] The composite restoration agent for groundwater restoration is made of the following materials in parts by mass: 24 parts of slag, 25 parts of oxygen release agent, 15 parts of Portland cement, 11 parts of filler, 17 parts of carbonized sludge, modified nano-zero price 14 parts of iron, 21 parts of pH buffer.

[0038] Described oxygen releasing agent is magnesium peroxide.

[0039] The filler is a mixture of zeolite and attapulgite in a mass ratio of 1:1.

[0040] The Portland cement is a mixture of ordinary Portland cement and composite Portland cement in a mass ratio of 1:1.

[0041] The pH buffering agent is kaolin.

[0042] The preparation method of the composite restoration agent for groundwater restoration comprises the following steps:

[0043] (1) The gasification slag is burned at a high temperature of 900°C-1250°C, expands, is cooled, crushed, and sieved to obtain slag particles with a particle size of 120 mesh;

[0044] (2) The air-dried sludge of domesti...

Embodiment 3

[0049] The composite restoration agent for groundwater restoration is made of the following materials in parts by mass: 14 parts of slag, 26 parts of oxygen release agent, 10 parts of Portland cement, 15 parts of filler, 15 parts of carbonized sludge, modified nano-zero price 15 parts of iron, 20 parts of pH buffer.

[0050] The oxygen release agent is magnesium peroxide.

[0051] The filler is zeolite.

[0052] The Portland cement is composite Portland cement.

[0053] Described pH buffering agent is tourmaline.

[0054] The preparation method of the composite restoration agent for groundwater restoration comprises the following steps:

[0055] (1) The gasification slag is burned at a high temperature of 900°C-1250°C, expands, is cooled, crushed, and sieved to obtain slag particles with a particle size of 120 mesh;

[0056] (2) The air-dried sludge of domestic sewage treatment plant has a moisture content of less than 10%, then crushed and passed through an 80-mesh sieve,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com