Bio-based slow/controlled-release coated nano cemented granulated fertilizer and preparation method thereof

A nano-cementation and bio-based technology, applied in the direction of layered/coated fertilizers, inorganic fertilizers, fertilizer mixtures, etc., can solve the problems of restricting wide application, high price, and difficult to achieve green food products, so as to solve the problem of raw material sources and reduce The effect of raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of nano fertilizer

[0040] Put 100g of halloysite nanotubes and 7g of urea into a ball milling reactor with a capacity of 1L, put 10 ceramic balls with a particle size of 1.8cm in the reactor, close the ball mill for 5 hours, and wash with isopropanol after the ball milling , until the unintercalated urea is washed away, and then dried to obtain the urea-intercalated nano-fertilizer;

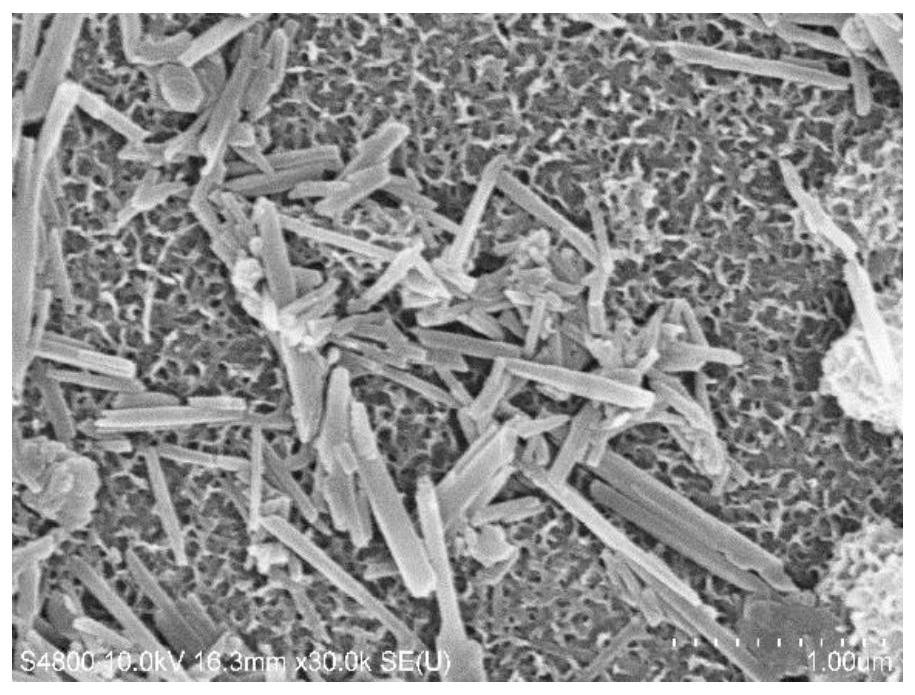

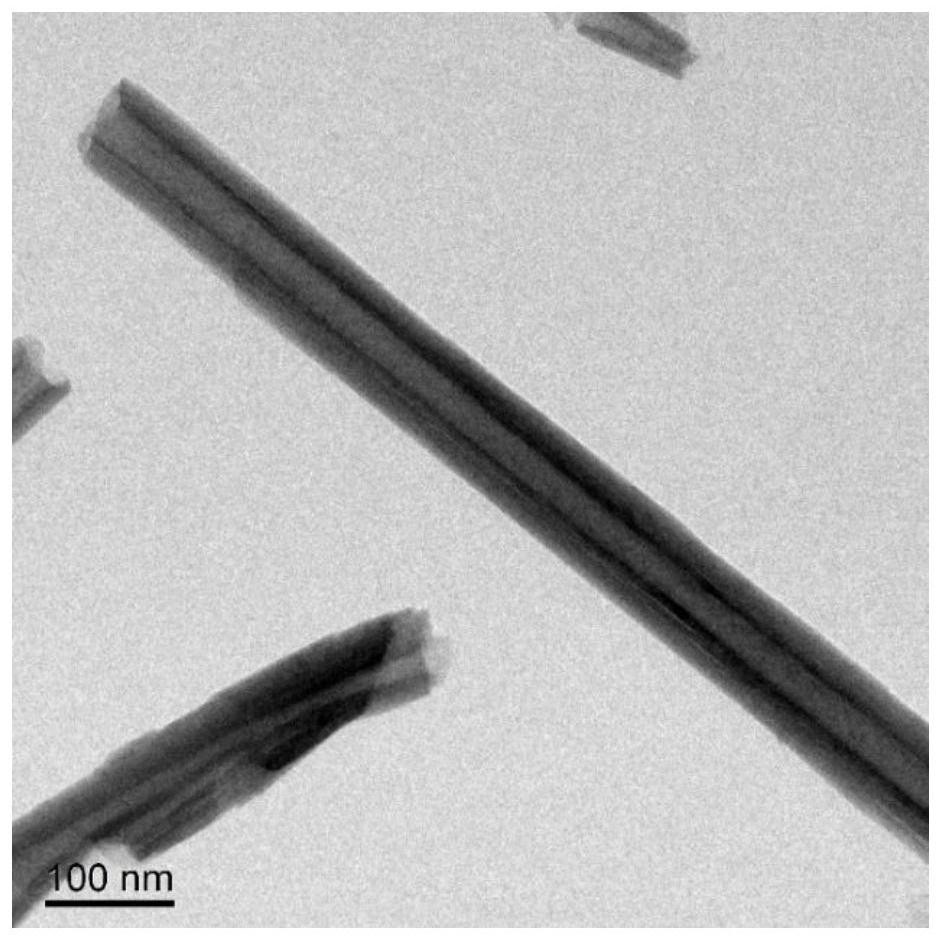

[0041] figure 1 It is the SEM figure of the halloysite nanotube before the present embodiment intercalation; figure 2 It is the SEM figure of the halloysite nanotube after the intercalation of the present embodiment.

[0042] (2) Preparation of granular fertilizer

[0043] Get 200g of nano-fertilizer, put it into a disc granulator, rotate continuously, and spray a polyvinyl alcohol solution (bonding agent) with a mass concentration of 0.1% on the surface of the nano-fertilizer, thereby rotating to form fertilizer particles, and put it drying in a blast drying at 70°C...

Embodiment 2

[0052] (1) Preparation of nano fertilizer

[0053] Put 100g of montmorillonite and 10g of potassium dihydrogen phosphate into a ball milling reactor with a capacity of 1L, put 10 ceramic balls with a particle size of 1.8cm in the reactor, and seal the ball mill for 5 hours. Wash until the unintercalated potassium dihydrogen phosphate is washed away, and then dry to obtain the intercalated nano-fertilizer of potassium dihydrogen phosphate;

[0054] (2) Preparation of granular fertilizer

[0055] Get 200g nano-fertilizer, put into disc granulator, rotate continuously, spray mass concentration is 2% chitosan (bonding agent) on the surface of nano-fertilizer, thereby rotate and form fertilizer granule, it is placed on drying in blast drying at 70°C to obtain fertilizer granules, wherein the amount of binder added is 10% of the weight of the natural nano-clay material;

[0056] (3) Preparation of coating agent

[0057] Grind 80g of wheat straw, pass through a 30-mesh sieve, mix ...

Embodiment 3

[0063] (1) Preparation of nano fertilizer

[0064] Put 100g of mesoporous silica and 20g of potassium chloride into a ball milling reactor with a capacity of 1L, put 10 ceramic balls with a particle size of 1.8cm in the reactor, and seal the ball mill for 5 hours. After the ball milling, use isopropanol Wash until the unintercalated potassium chloride is washed away, and then dry to obtain the nano-fertilizer of potassium chloride intercalation;

[0065] (2) Preparation of granular fertilizer

[0066] Get 200g nano-fertilizer, put into disc granulator, rotate continuously, spray mass concentration is 1% xanthan gum (binder) on the surface of nano-fertilizer, thereby rotate to form fertilizer granule, put it on drying in blast drying at 70°C to obtain fertilizer granules, wherein the amount of binder added is 35% of the weight of the natural nano-clay material;

[0067] (3) Preparation of coating agent

[0068] Grind 100g of corn stalks, pass through a 30-mesh sieve, mix it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com