Silanized boron nitride modified super-hydrophobic sponge for oil/water separation and preparation method of silanized boron nitride modified super-hydrophobic sponge

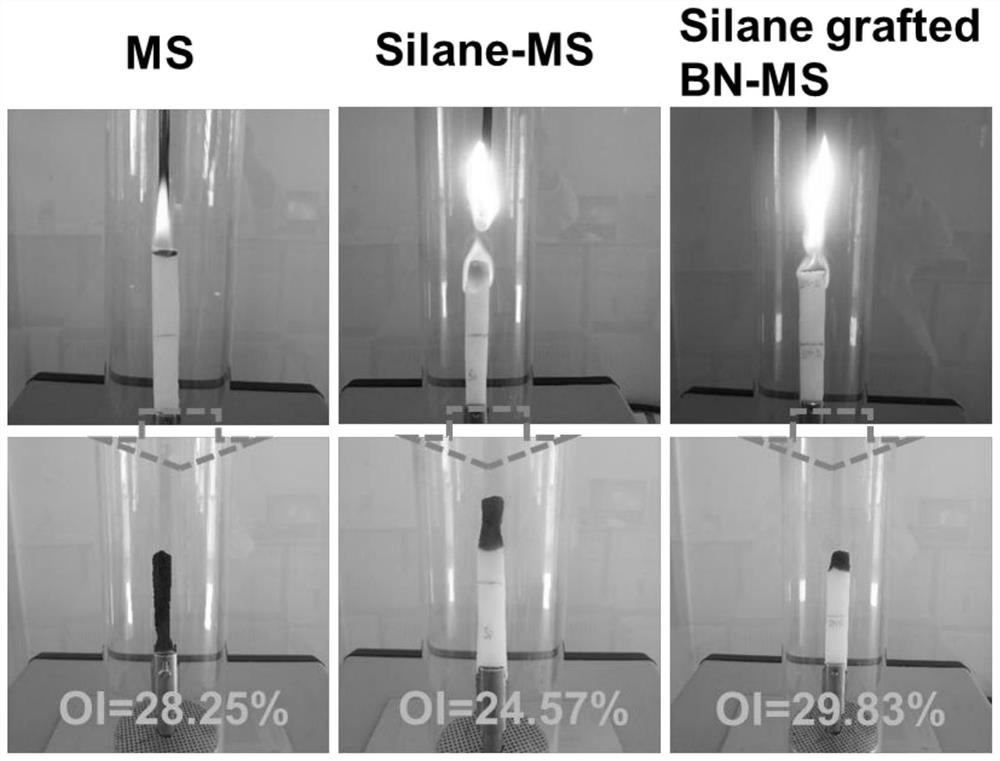

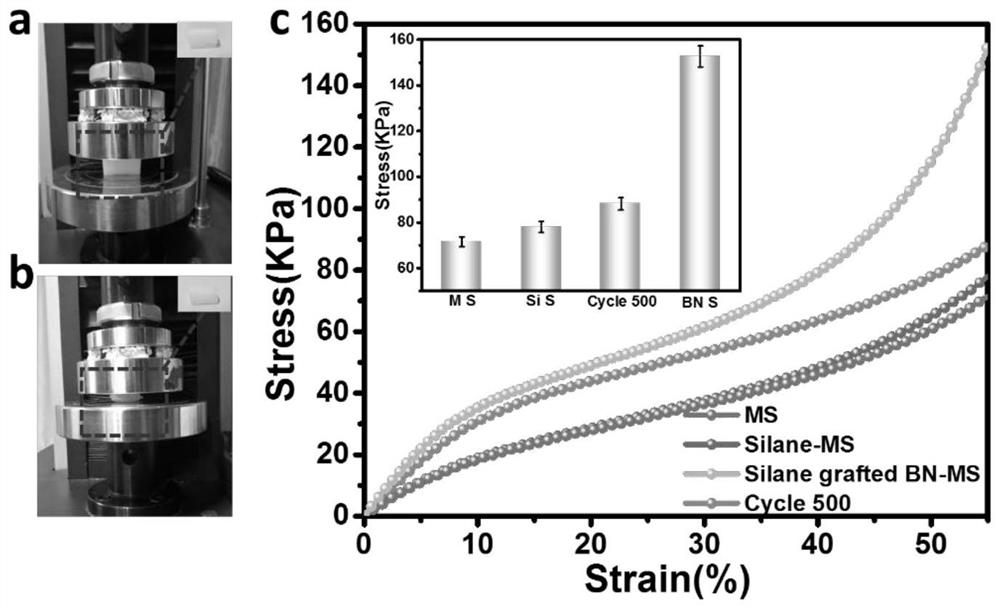

A super-hydrophobic sponge, boron nitride technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of unstable sponge and limit large-scale application, and achieve excellent flame retardant properties and compressive properties, The effect of overcoming the interface compatibility problem and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

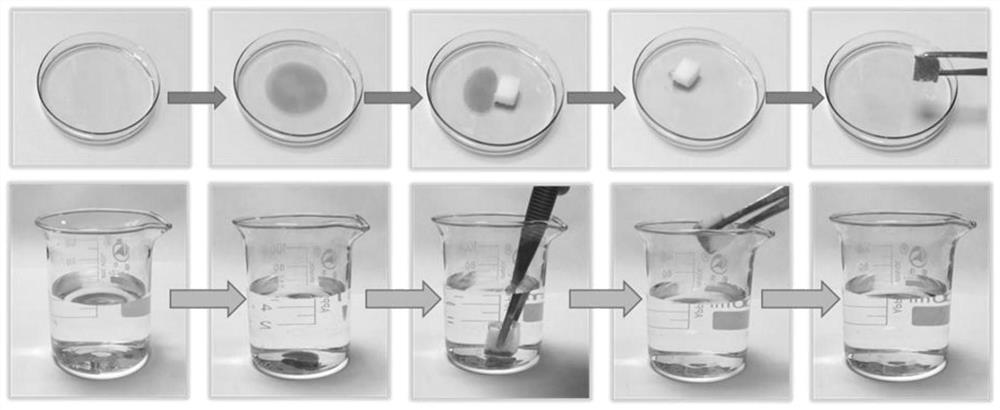

[0026] A silanized boron nitride modified superhydrophobic sponge for efficient oil / water separation, the preparation method comprising the following specific steps:

[0027] 1) Preparation of hydroxylated boron nitride: uniformly grind the mixture of KOH (2.0600g), NaOH (2.7160g) and h-BN powder (1g). After milling, the above mixture was further transferred to a polytetrafluoroethylene (PTFE) stainless steel autoclave. Subsequently, the system was heated at 180° C. for 2 hours. The mixture was taken out and cooled to room temperature. The solid product was collected and washed repeatedly with ethanol and deionized water until the pH of the filtrate was close to neutral. Finally, the solution is centrifuged to obtain hydroxylated boron nitride powder, which is dried and used;

[0028] 2) Preparation of silylated boron nitride: at 90°C, carry out silane coupling reaction in a mixture of octadecyltrimethoxysiloxane (0.5mL) and hydroxylated boron nitride (0.05g) in ethanol and...

Embodiment 2

[0031] A method for preparing a silanized boron nitride-modified superhydrophobic sponge for efficient oil / water separation, step 1) and step 2) are the same as in Example 1.

[0032] Step 3) Prepare the silylated boron nitride modified sponge, immerse the commercial melamine sponge in the suspension solution containing 10wt% silylated boron nitride modified, and the reaction time is half an hour. After the reaction, the unreacted boron nitride and silane on the surface of the sponge were cleaned with acetone solution, and dried in an oven at 80°C for 5 hours. The prepared sponge was marked as Silane-BN@10%.

Embodiment 3

[0034] A method for preparing a silanized boron nitride-modified superhydrophobic sponge for efficient oil / water separation, step 1) and step 2) are the same as in Example 1.

[0035] Step 3) Prepare the silylated boron nitride modified sponge, immerse the commercial melamine sponge in the suspension solution containing 15wt% silylated boron nitride modified, and the reaction time is half an hour. After the reaction, the unreacted boron nitride and silane on the surface of the sponge were cleaned with acetone solution, and dried in an oven at 80°C for 5 hours. The prepared sponge was marked as Silane-BN@15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com