PLA-PBAT blending modified degradable material

A technology of degradable materials and blending modification, applied in the field of polymer materials, can solve the problems of low thermal stability, high cost, slow crystallization, etc., and achieve the effects of improved mechanical properties, good degradation performance, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

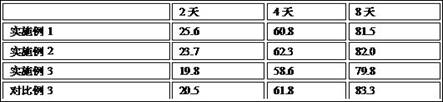

Examples

Embodiment 1

[0028]A PLA-PBAT blending modified degradable material, the preparation method of the material includes:

[0029]S1: Use a desiccant dryer to dry PLA, PBAT, and polyglycidyl methacrylate grafted starch to avoid hydrolysis during the preparation process; according to the weight ratio, the ratio of PLA:PBAT is 60:40, The amount of glycidyl acrylate grafted starch is 1.0% of the total weight of PLA and PBAT.

[0030]S2: Put the PLA, PBAT and polyglycidyl methacrylate grafted starch powder obtained by drying in S1 into a mixer and mix well;

[0031]S3: The uniform raw materials obtained in S2 are added to the twin-screw extruder for melting and mixing, the temperature is 185°C, and the speed is 50 r / min;

[0032]S4: The molten material obtained in S3 is added to the granulation machine to obtain the PLA-PBAT blend modified degradable material.

Embodiment 2

[0034]A PLA-PBAT blending modified degradable material, the preparation method of the material includes:

[0035]S1: Use a desiccant dryer to dry PLA, PBAT, and polyglycidyl methacrylate grafted starch to avoid hydrolysis during the preparation process; according to the weight ratio, the ratio of PLA:PBAT is 70:30, The amount of glycidyl acrylate grafted starch is 0.5% of the total weight of PLA and PBAT.

[0036]S2: Put the PLA, PBAT and polyglycidyl methacrylate grafted starch powder obtained by drying in S1 into a mixer and mix well;

[0037]S3: The uniform raw materials obtained in S2 are added to the twin-screw extruder for melting and mixing, the temperature is 190°C, and the speed is 50 r / min;

[0038]S4: The molten material obtained in S3 is added to the granulation machine to obtain the PLA-PBAT blend modified degradable material.

Embodiment 3

[0040]A PLA-PBAT blending modified degradable material, the preparation method of the material includes:

[0041]S1: Use a desiccant dryer to dry PLA, PBAT, and polyglycidyl methacrylate grafted starch to avoid hydrolysis during the preparation process; according to the weight ratio, the ratio of PLA:PBAT is 60:40, The amount of glycidyl acrylate grafted starch is 2.0% of the total weight of PLA and PBAT.

[0042]S2: Put the PLA, PBAT and polyglycidyl methacrylate grafted starch powder obtained by drying in S1 into a mixer and mix well;

[0043]S3: The uniform raw materials obtained in S2 are added to the twin-screw extruder for melting and mixing, the temperature is 190°C, and the speed is 50 r / min;

[0044]S4: The molten material obtained in S3 is added to the granulation machine to obtain the PLA-PBAT blend modified degradable material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com