Metallized wood wave-absorbing plate and preparation method thereof

A metallized and wood-based technology, applied in the direction of chemical instruments and methods, metal layered products, layered products, etc., can solve the problems of increased cost and difficulty in manufacturing, and achieve the effect of strong microwave absorption, good toughness, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

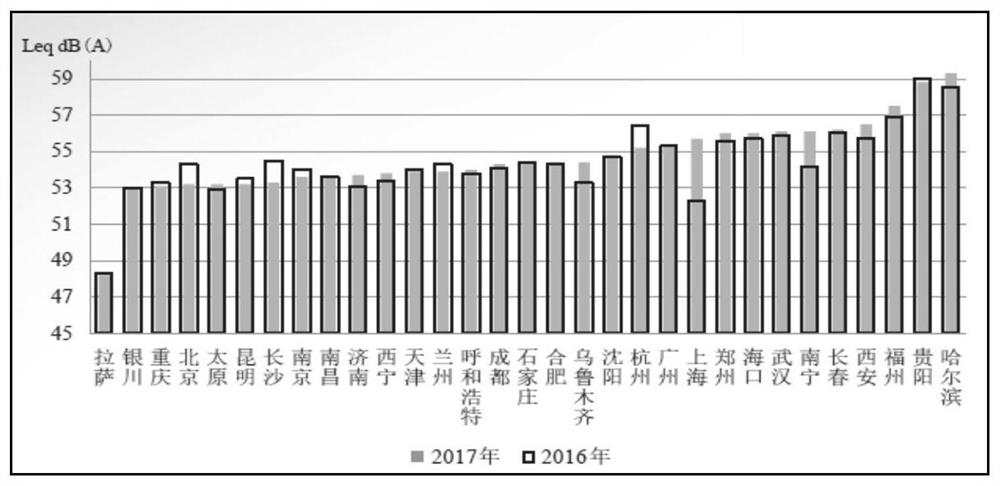

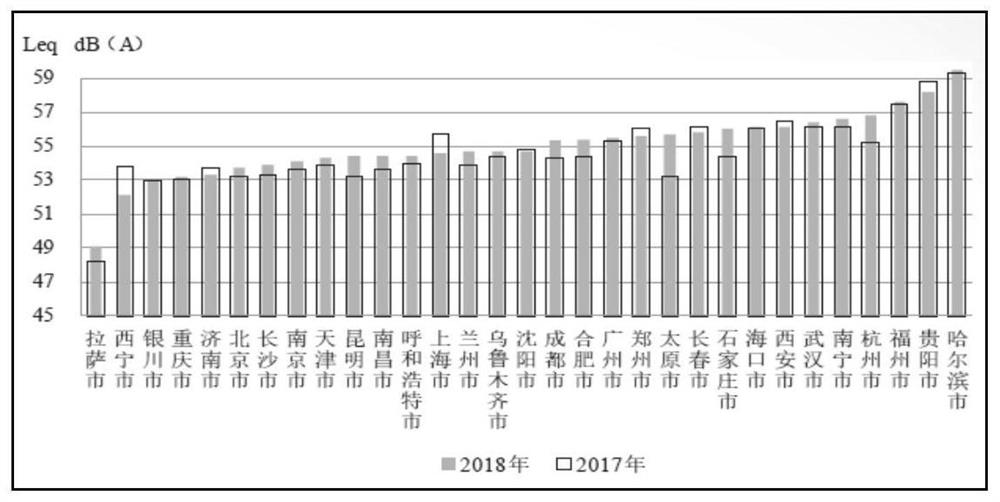

Image

Examples

Embodiment 1

[0039] A metallized wooden wave-absorbing plate, which is made of three materials: cotton stalk-based composite powder and brass screen in a weight ratio of 1:1:1; the cotton stalk-based composite The powder is composed of 30% cotton stalk powder, 25% sendustam absorbing powder, 30% metal nickel powder, and 15% thermoplastic toughened polyimide resin powder by weight percentage; the preparation of the cotton stalk-based composite powder The method includes the following steps:

[0040](1) Cotton stalk extraction pretreatment: vacuum-dry the cotton stalk to control its moisture content to 15%, then soak it in 5% NaOH solution at room temperature for 15 hours, rinse and dry to reduce the hemicellulose content. Reduced by 30%, then soaked in a 1:1 "acetic acid + hydrogen peroxide" solution at room temperature for 3 hours, rinsed and dried to reduce the lignin content by 30%, and the pretreated cotton stalks were obtained for the preparation of cotton stalk powder for subsequent u...

Embodiment 2

[0048] A metallized wooden wave-absorbing board, the board is made of cotton stem lotus root scraps, cotton stem-based composite powder, and brass screen in a weight ratio of 2:2:1; the cotton stem-based composite The powder is composed of 40% cotton stem powder, 30% sendust wave absorbing powder, 20% metallic nickel powder, and 10% thermoplastic toughened polyimide resin powder in terms of weight percentage; the preparation of the cotton stem-based composite powder The method includes the following steps:

[0049] (1) Cotton stalk extraction pretreatment: vacuum dry the cotton stalk to control its moisture content to 20%, then soak it in 10% NaOH solution at room temperature for 5 hours, rinse and dry to reduce the hemicellulose content. Reduced by 40%, then soaked in a 1:1 "acetic acid + hydrogen peroxide" solution at room temperature for 5 hours, rinsed and dried to reduce the lignin content by 40%, to obtain pretreated cotton stems for the preparation of cotton stem powder...

Embodiment 3

[0057] A metallized wooden wave-absorbing plate, which is made of three materials: cotton stalk-based composite powder and brass screen in a weight ratio of 1:1:1; the cotton stalk-based composite The powder is composed of 32% of cotton stem powder, 35% of sendust wave absorbing powder, 23% of metal nickel powder, and 10% of thermoplastic toughened polyimide resin powder in terms of weight percentage; the preparation of the cotton stem-based composite powder The method includes the following steps:

[0058] (1) Cotton stalk extraction pretreatment: vacuum dry the cotton stalk to control its moisture content at 16%, then soak it in 8% NaOH solution for 10 hours at room temperature, rinse and dry to reduce the hemicellulose content. Reduced by 35%, then soaked in a 1:1 "acetic acid + hydrogen peroxide" solution at room temperature for 4 hours, rinsed and dried to reduce the lignin content by 35%, to obtain pretreated cotton stems for the preparation of cotton stem powder for sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com