Cunisi alloy cable sheathing

A technology of alloy and inner sheath, which is applied in the direction of submarine cables, insulated cables, power cables with shielding layer/conductive layer, etc., and can solve the problems of fatigue characteristics decline and limitation in longitudinal welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

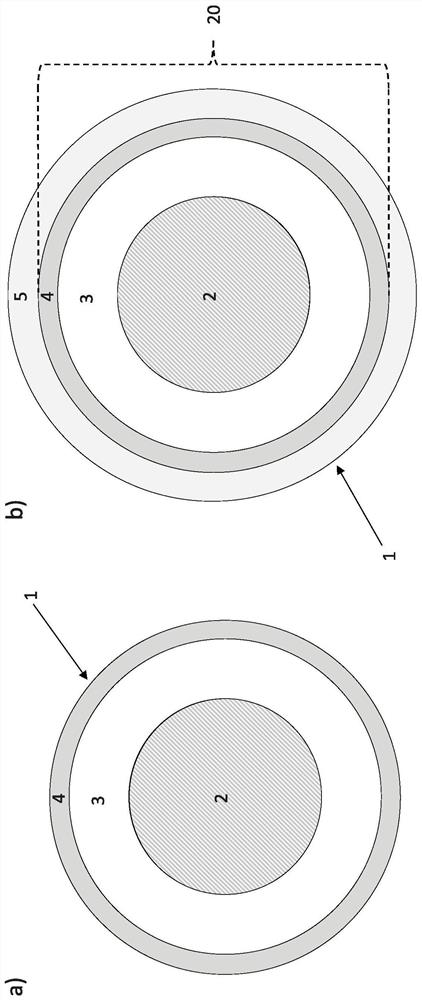

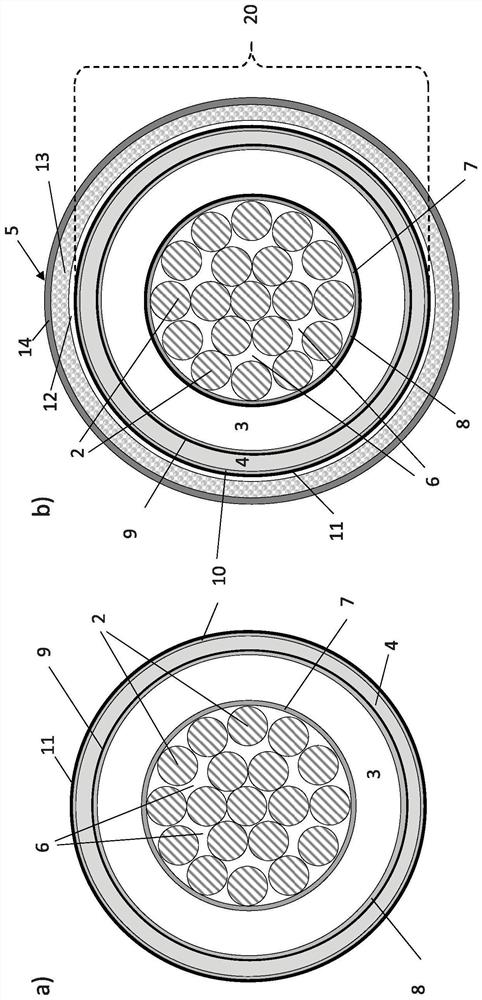

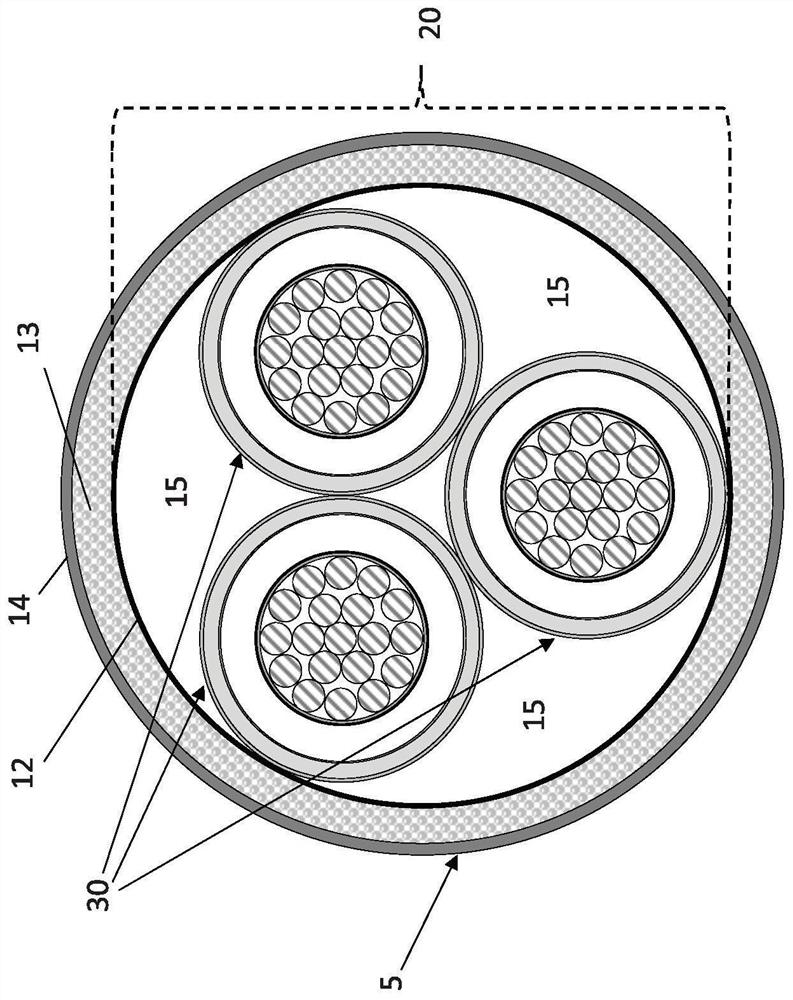

[0047] The invention will be further described by way of example embodiments.

[0048] Example Embodiment 1

[0049] Example Embodiment 1 is in figure 2 A single conductor power cable schematically shown in a) and 2b). These figures show cross-sectional views. figure 2 a) illustrates the single conductors forming the core of the cable. The cable core comprises at its center an electrical conductor (2) made of 400mm of conductive pitch (ETP) Cu 2 Made of drawn and twisted wire. Alternatively, the strands of conductors may be made of AA1370 aluminum alloy or AA6101 aluminum alloy. The conductor is impregnated by filling the spaces between the individual strands of the conductor with a commercially available water sealant (6), such as eg a silicone sealant, to provide a longitudinal water barrier.

[0050] The conductor (2) is given a first layer of semiconducting polyethylene (PE) (7) with a thickness of 1.5 mm to relieve electrical stress concentrations around the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com