Composition, electrolyte containing composition and lithium ion battery

A composition and electrolyte technology, applied in the field of batteries, can solve problems such as low-temperature cycle improvement effect, failure to meet new needs, instability, etc., to improve high-temperature and low-temperature performance of batteries, overcome high-temperature and low-temperature performance of batteries, reduce The effect of battery internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

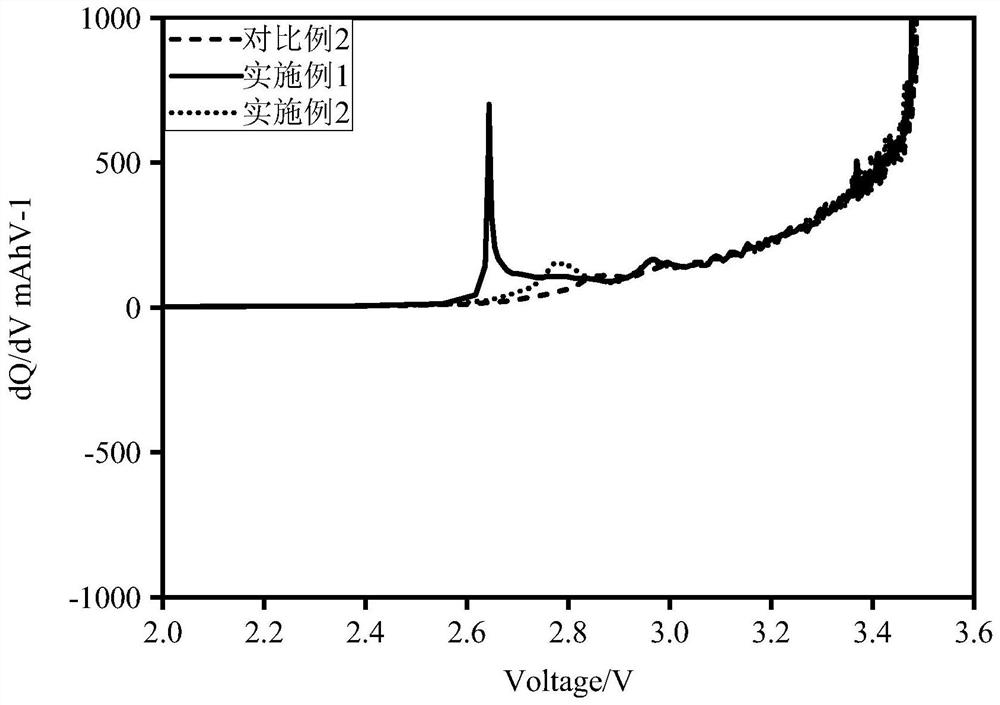

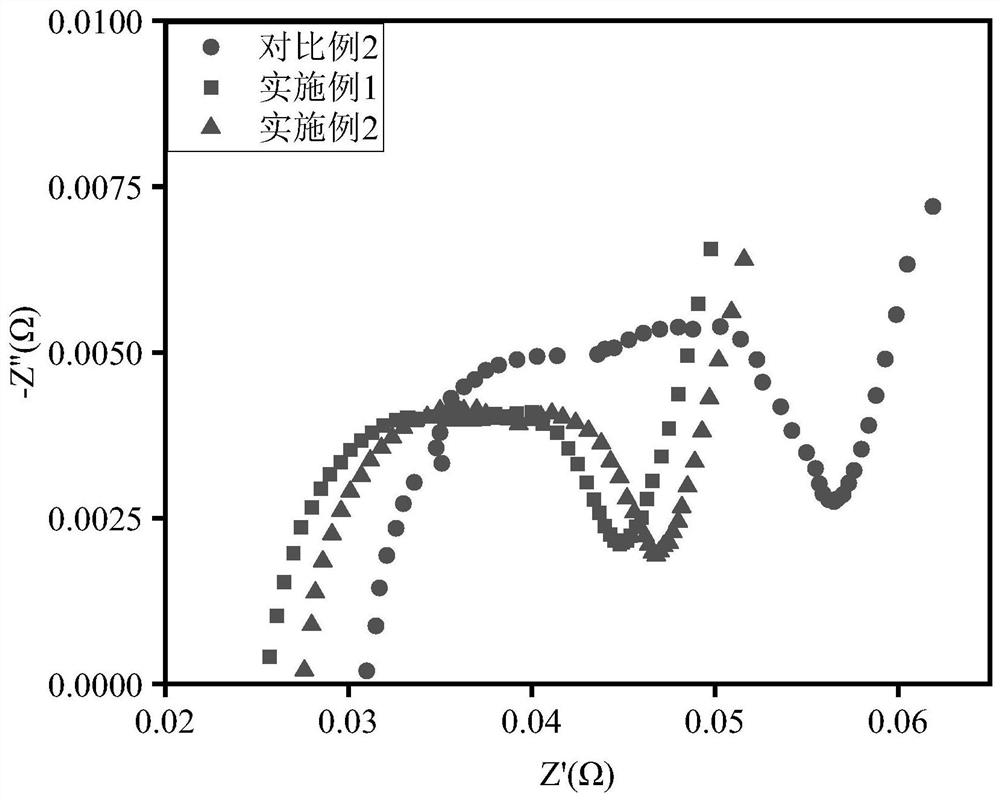

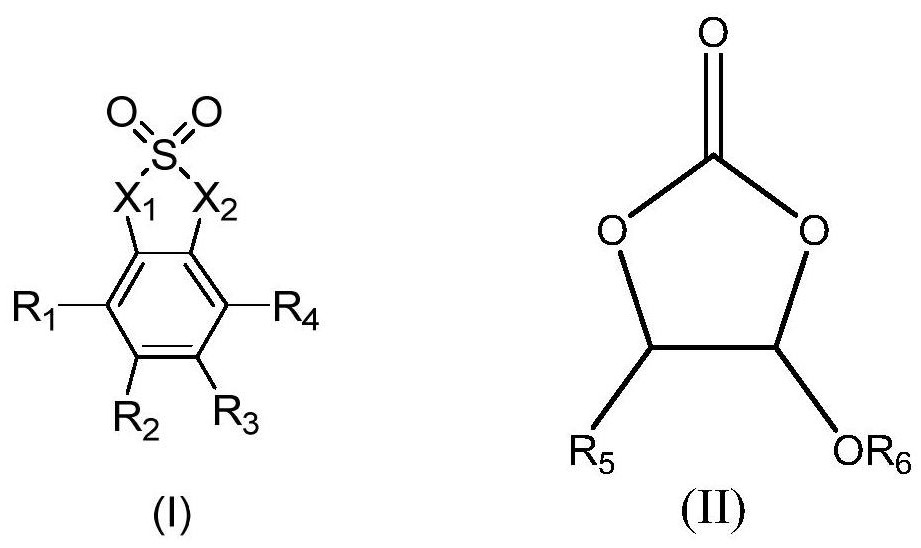

Embodiment 1

[0086] In this embodiment, the additives are selected from the above chemical formula I2 and chemical formula II1, and the additives I2 and II1 account for 0.03% and 1% of the weight of the electrolyte respectively; the lithium salt is lithium hexafluorophosphate, and the lithium salt accounts for 13% of the weight of the electrolyte; the solvent is A solvent mixed with ethylene carbonate and dimethyl carbonate at a weight ratio of 1:2; the positive electrode material is LiNi 0.8 co 0.1 mn 0.1 o 2 ; Negative electrode material is artificial graphite; Diaphragm is polyethylene film. Assemble into a pouch battery according to the conventional method.

Embodiment 2

[0088] In this embodiment, the additives are selected from the above chemical formula I2 and chemical formula II1, and the additives I2 and II1 account for 1% and 0.1% of the weight of the electrolyte respectively; the lithium salt is lithium hexafluorophosphate, and the lithium salt accounts for 13% of the weight of the electrolyte; the solvent is A solvent mixed with ethylene carbonate and dimethyl carbonate at a weight ratio of 1:2; the positive electrode material is LiNi 0.8 co 0.1 mn 0.1 o 2 ; Negative electrode material is artificial graphite; Diaphragm is polyethylene film. Assemble into a pouch battery according to the conventional method.

Embodiment 3

[0090] In this embodiment, the additives are selected from the above chemical formula I2 and chemical formula II1, and the additives I2 and II1 account for 1% and 1% of the weight of the electrolyte respectively; the lithium salt is lithium hexafluorophosphate, and the lithium salt accounts for 13% of the weight of the electrolyte; the solvent is A solvent mixed with ethylene carbonate and dimethyl carbonate at a weight ratio of 1:2; the positive electrode material is LiNi 0.8 co 0.1 mn 0.1 o 2 ; Negative electrode material is artificial graphite; Diaphragm is polyethylene film. Assemble into a pouch battery according to the conventional method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com