Gel polymer lithium ion battery and preparation method thereof

A technology of lithium-ion batteries and gel polymers, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc., can solve the problem of complex extraction process of plasticizers, which is difficult to popularize and apply on a large scale, battery Yield decline and other problems, to achieve the effect of excellent performance such as high temperature, small increase in internal resistance of the battery cell, and easy control of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 100.00 g of P(VDF-HFP) powder with a mass ratio of HFP:VDF of 15:100 was dissolved in 4.35 kg of tetrahydrofuran and 0.5 Kg of dimethyl sulfoxide to prepare a P(VDF-HFP) solution. 20.00gSiO 2 The ultrafine powder is dispersed in the above P(VDF-HFP) solution and mixed evenly. Then slowly inject 50.00 g of dimethyl carbonate, stir evenly, and age to prepare a separator coating slurry.

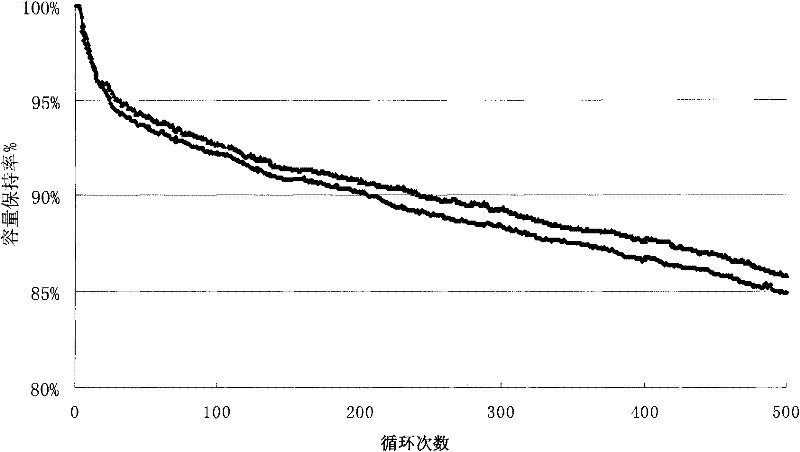

[0027] The membrane coating slurry obtained above was coated on the surface of the base membrane by a spraying method, and then baked and dried at 55° C. to prepare a porous composite membrane. Assemble the above-mentioned porous composite diaphragm and positive and negative electrode sheets into a 303443P (380mAh) battery, inject liquid lithium salt electrolyte, and bake the battery for 8.0 hours at a pressure of 0.7MPa and a temperature of 75°C after aging, and then perform a After pre-charging, aging, and capacity separation, a gel polymer battery is made, and the cell number is cell...

Embodiment 2

[0029] 250.00 g of P(VDF-HFP) powder with a HFP:VDF mass ratio of 12:100 was dissolved in 4.43 kg of acetone to prepare a P(VDF-HFP) solution. Add 25.00g Al 2 o 3 The ultrafine powder is dispersed in the above P(VDF-HFP) solution and mixed evenly. Then slowly inject 300.00 g of deionized water, stir evenly, and age to prepare a membrane coating slurry.

[0030] The membrane coating slurry obtained above is coated on the surface of the base membrane by a dip coating method, and after being dried at room temperature, a porous composite membrane is prepared. Assemble the above-mentioned porous composite diaphragm and positive and negative electrode sheets into a 303443P (380mAh) battery, inject liquid electrolyte, precharge the battery cell after aging, and then bake the battery at 85°C for 5.0 hours with a pressure of 0.4MPa. h, after aging and capacity-dividing the battery cell, a gel polymer battery is made, and the battery cell number is cell 2. The measured internal resi...

Embodiment 3

[0032] 500.00 g of P(VDF-HFP) powder with a mass ratio of HFP:VDF of 20:100 was dissolved in 3.75 kg of butanone to prepare a P(VDF-HFP) solution. Then 450.00gZrO 2 The ultrafine powder is dispersed in the above P(VDF-HFP) solution and mixed evenly. Then slowly inject a mixture of 100.00 g of n-butanol, 100 g of diethyl carbonate and 100 g of methyl propyl carbonate, stir evenly and then age to prepare a separator coating slurry.

[0033] The membrane coating slurry obtained above was coated on the surface of the base membrane by a roller coating method, and after being baked and dried at 50° C., a porous composite membrane was prepared. Assemble the above-mentioned porous composite diaphragm and positive and negative electrode sheets into a 303443P (380mAh) battery, then inject liquid lithium salt electrolyte, precharge the battery cell after aging, and then dry the battery at a pressure of 1.0MPa and a temperature of 65°C Baking for 10.0 hours, after aging and capacity sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com