Preparation method of photocatalytic floating beads

A technology of photocatalysis and floating beads, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of reducing loss and self-damage and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of photocatalytic floating beads, comprising the following steps:

[0034] a. Pretreatment of floating beads: soak the floating beads with 10% dilute acid for 6 hours at room temperature, and then rinse with distilled water until the outflowing water is neutral. Select floating beads and dry them for later use;

[0035] b. TiO 2 Preparation of sol: using butyl titanate, absolute ethanol, acetylacetone, distilled water and hydrochloric acid as raw materials, the molar ratio of butyl titanate, absolute ethanol, acetylacetone, distilled water and hydrochloric acid is 1:16:1:6: 0.6, first dissolve butyl titanate in ethanol, add acetylacetone, slowly add water and hydrochloric acid under stirring, continue stirring for 5-6 hours, and then age to obtain yellow transparent TiO 2 Sol;

[0036] c. Load TiO 2 Preparation of floating beads: TiO 2Add the floating bead carrier pretreated in step a to the sol, so that the mass ratio of butyl titanate to float...

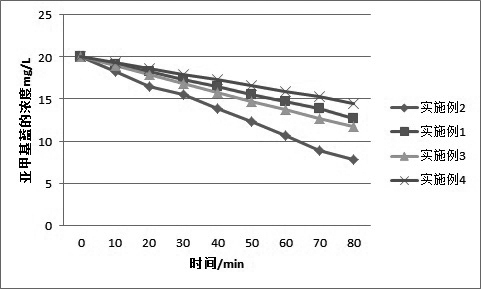

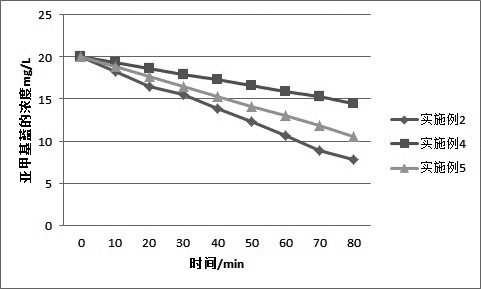

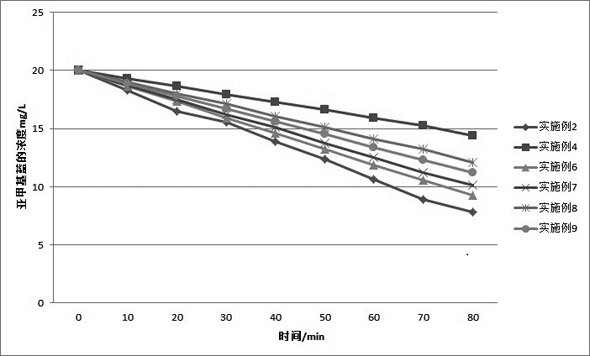

Embodiment 2

[0042] A preparation method of photocatalytic floating beads, comprising the following steps:

[0043] a. Pretreatment of floating beads: soak the floating beads with 10% dilute acid for 6 hours at room temperature, and then rinse with distilled water until the outflowing water is neutral. Select floating beads and dry them for later use;

[0044] b. TiO 2 Preparation of sol: using butyl titanate, absolute ethanol, acetylacetone, distilled water and hydrochloric acid as raw materials, the molar ratio of butyl titanate, absolute ethanol, acetylacetone, distilled water and hydrochloric acid is 1:16:1:6: 0.6, first dissolve butyl titanate in ethanol, add acetylacetone, slowly add water and hydrochloric acid under stirring, continue stirring for 5-6 hours, and then age to obtain yellow transparent TiO 2 Sol;

[0045] c. Load TiO 2 Preparation of floating beads: TiO 2 Add the floating bead carrier pretreated in step a to the sol, so that the mass ratio of butyl titanate to floa...

Embodiment 4

[0061] A preparation method of photocatalytic floating beads, comprising the following steps:

[0062] a. Floating beads pretreatment: Soak the floating beads in 10% dilute nitric acid for 6 hours at room temperature, then rinse with distilled water until the outflowing water is neutral, choose floating beads, and dry them for later use;

[0063] b. TiO 2 Preparation of sol: using butyl titanate, absolute ethanol, acetylacetone, distilled water and hydrochloric acid as raw materials, the molar ratio of butyl titanate, absolute ethanol, acetylacetone, distilled water and hydrochloric acid is 1:16:1:6: 0.6, first dissolve butyl titanate in ethanol, add acetylacetone, slowly add water and hydrochloric acid under stirring, continue stirring for 5-6 hours, and then age to obtain yellow transparent TiO 2 Sol;

[0064] c. Load TiO 2 Preparation of floating beads: TiO 2 Add the floating bead carrier pretreated in step a to the sol, so that the mass ratio of butyl titanate to float...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com