Metal organic framework Mn-MOF single-crystal material, nanosheet, preparation and application

A metal-organic framework and single-crystal material technology, which is applied in the field of photocatalytic materials to achieve the effects of simple and easy preparation method, good photocatalytic water splitting hydrogen production performance, and adjustable thickness range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: Synthesis of metal organic framework Mn-MOF single crystal material

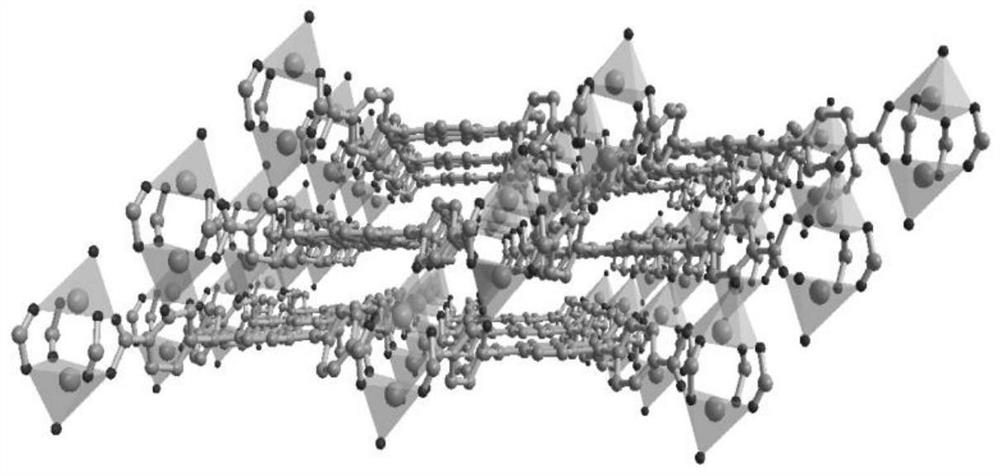

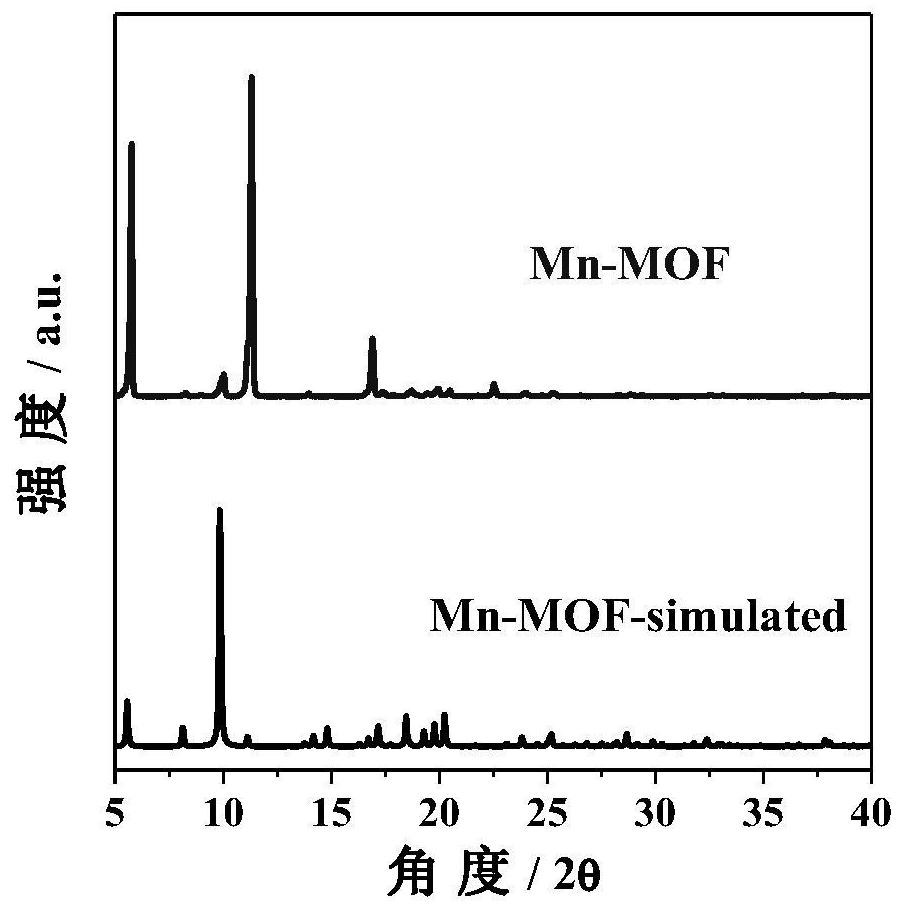

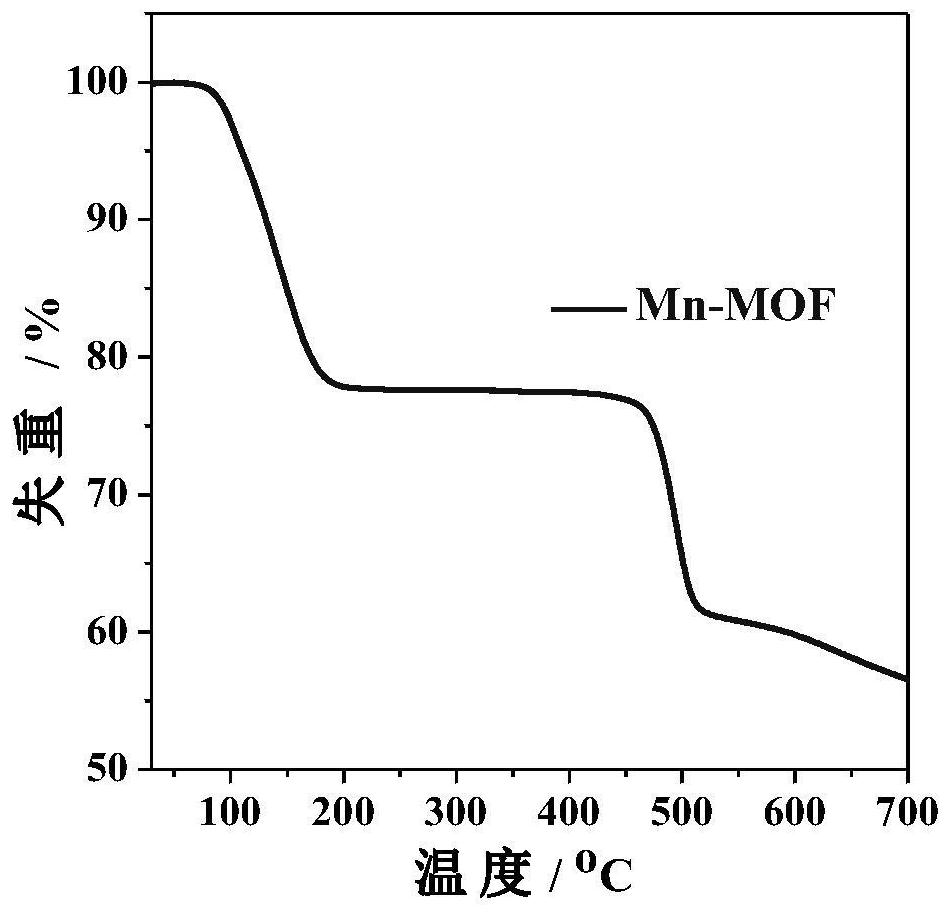

[0048] Weigh manganese chloride tetrahydrate (29.7mg, 0.15mmol), H 4tbapy (66.6mg, 0.1mmol) was added to a 25ml polytetrafluoroethylene-lined hydrothermal reactor, followed by adding 2ml N,N-dimethylformamide, 1ml 1,4-dioxane and 1ml water, Transfer the polytetrafluoroethylene-lined hydrothermal reactor to the oven, and use the programmed temperature control method to raise the temperature from room temperature to 130°C at a heating rate of 40°C / h, then keep it warm for 72h, and the cooling rate is 2°C / h, down to At room temperature, yellow crystals were obtained. After washing with N,N-dimethylformamide, suction filtration, and natural drying at room temperature, the target material Mn-MOF was obtained with a yield of about 85% (based on H 4 calculated by tbapy). The prepared metal-organic framework Mn-MOF single crystal material structure is as follows figure 1 As shown, the Mn-MOF ...

Embodiment 2

[0052] Embodiment 2: Preparation of Mn-MOF nanosheets

[0053] Weigh 50 mg of the Mn-MOF single crystal material prepared in Example 1, and add it to 3 ml of acetonitrile and water in a mixed solvent whose ratios are 1:0, 6:1, 5:1, and 4:1, that is, the ratio of acetonitrile and water The volumes are 3ml and 0ml, 2.57ml and 0.43ml, 2.5ml and 0.5ml, 2.4ml and 0.6ml respectively, and the Mn-MOF nanosheet sample Mn -M-2h, Mn-M-H-6-1-2h, Mn-M-H-5-1-2h, Mn-M-H-4-1-2h.

[0054] This example mainly investigates the effect of the ratio of acetonitrile and water on the morphology of the prepared Mn-MOF nanosheets. The TEM photos of Mn-MOF nanosheets prepared under different solvent ratios are shown in Figure 5 , the figure shows that the addition of water has a significant effect on the morphology of Mn-MOF nanosheets, and the sample Mn-M-H-5-1-2h prepared when the ratio of acetonitrile and water is 5:1 has the most regular rectangular shape. The XRD patterns of Mn-MOF nanosheets p...

Embodiment 3

[0055] Embodiment 3: Preparation of Mn-MOF nanosheets

[0056] Measure 2.5ml of acetonitrile and 0.5ml of water to prepare a total of 3ml of acetonitrile and water mixed solution, weigh 50mg of the Mn-MOF single crystal material prepared in Example 1, and add it to the above mixed solution. When the ultrasonic frequency is 40kHz and the output power is Under the condition of 500W, ultrasonic 2h, 3h, 4h, 5h, respectively, to obtain Mn-MOF nanosheet samples Mn-M-H-5-1-2h, Mn-M-H-5-1-3h, Mn-M-H-5-1- 4h, Mn-M-H-5-1-5h.

[0057] This example mainly investigates the effect of ultrasonic time on the preparation of Mn-MOF nanosheets when the ratio of acetonitrile and water is 5:1. The TEM photos of Mn-MOF nanosheets prepared under different ultrasonic times are shown in Figure 7 , the figure shows that the prepared Mn-MOF nanosheets are all regular rectangular thin flakes, and the ultrasonic time has no significant effect on the shape size of the nanosheets. The thickness of the M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com