Down producing goat insemination injector

A technology of syringes and cashmere goats, which is applied in the field of animal artificial insemination auxiliary equipment, can solve the problems of poor control of outdoor sunlight, large temperature changes in spring and autumn, and decreased sperm freshness rate, so as to improve the amount of fertilization and work efficiency, and prolong freshness. The effect of high efficiency, mobile operation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

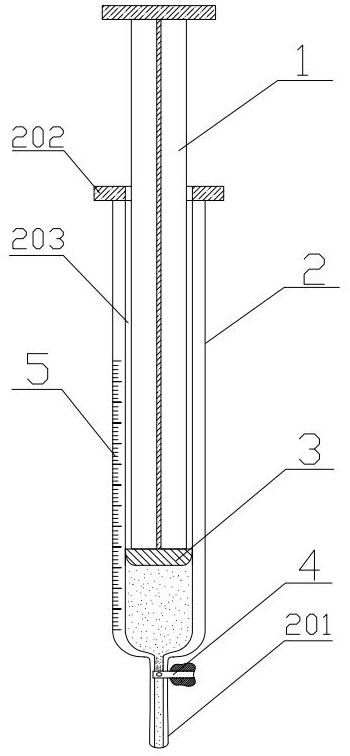

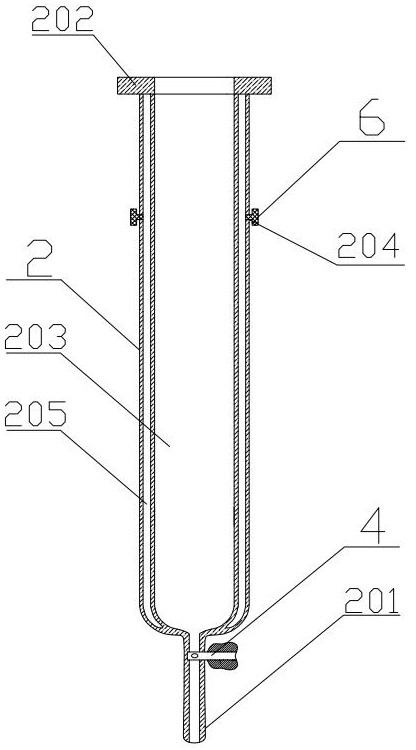

[0018] as attached Figure 1-2 A cashmere goat insemination syringe shown includes a push rod 1, an injection tube 2, an injection nozzle 201, a booster part 202, a liquid chamber 203, a liquid injection hole 204, a heat preservation chamber 205, a piston 3, a valve 4, and a scale line 5 and blockage 6, the upper end of the injection tube 2 is provided with a booster part 202, the middle part of the injection tube 2 is provided with a liquid holding chamber 203, the liquid holding chamber 203 is in the shape of a circular tube, and the inside of the liquid holding chamber 203 is provided with a push rod 1, and the push rod 1 The lower part is provided with a piston 3, the circumferential wall of the piston 3 is in interference fit with the inner wall of the liquid chamber 203, and is driven by the push rod 1 to move telescopically in the liquid chamber 203; the outer wall surface of the injection tube 2 is provided with a scale mark 5. The lower part of the injection tube 2 is...

Embodiment 2

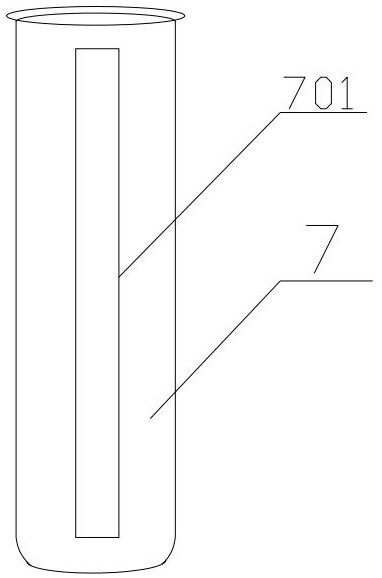

[0021] In another embodiment, as attached Figure 3-4 , the outer layer of the injection tube 2 can also be provided with a deep cool color sleeve 7 to avoid the damage of ultraviolet rays to sperm during the semen injection operation; one side of the deep cool color sleeve 7 is provided with a scale display window 701, so that the exposed scale line 5 for easy reading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com