Degassing process for producing sodium hexadecyl sulfonate

A technology for a mixture of sodium cetyl sulfonate and alkylsulfonyl chloride, which is applied in the preparation of sulfonate, products, and organic compounds, and can solve the problem of high impurity content of sodium cetyl sulfonate, cetane Low purity of sulfonyl chloride, complex degassing process and other problems, to achieve the effect of great application value, high yield and convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A degassing process for producing sodium cetyl sulfonate, comprising the following steps:

[0031] The first step is to add heavy oil into the reaction kettle, and under the light of ultraviolet light, pass the mixed gas of chlorine gas and sulfur dioxide into the reaction kettle according to the volume ratio of 1:2, control the temperature in the reaction kettle to 31 ℃, and the rotation speed to 100r / min Under the conditions, react for 3h to obtain a mixture of alkylsulfonyl chlorides;

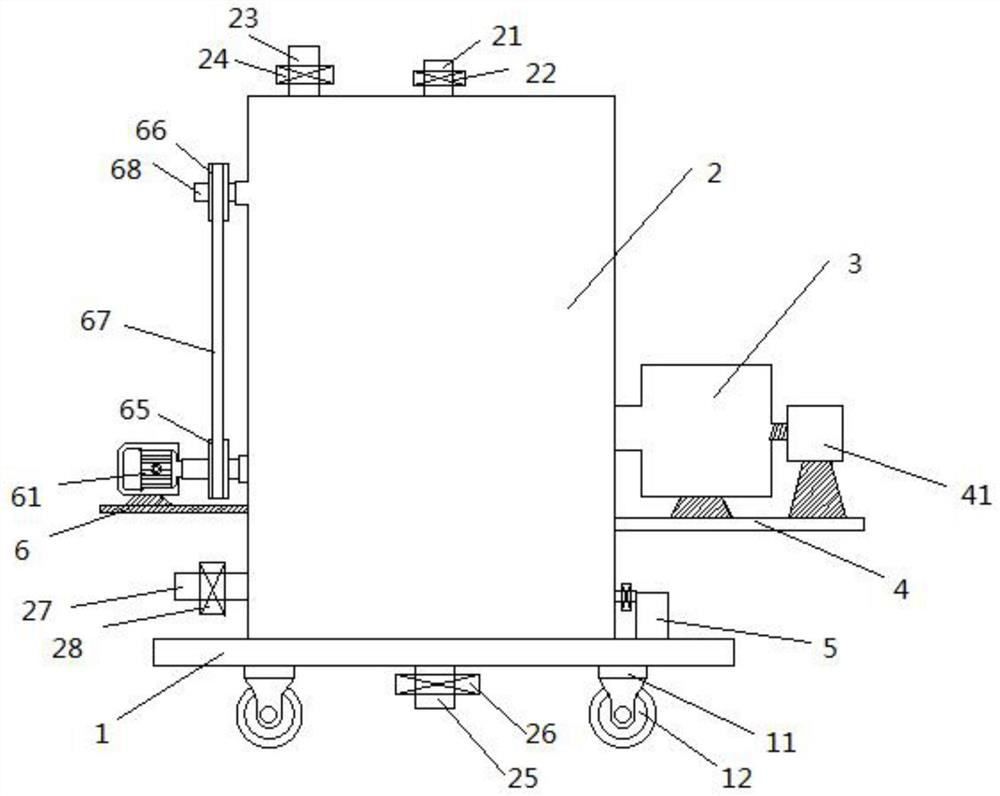

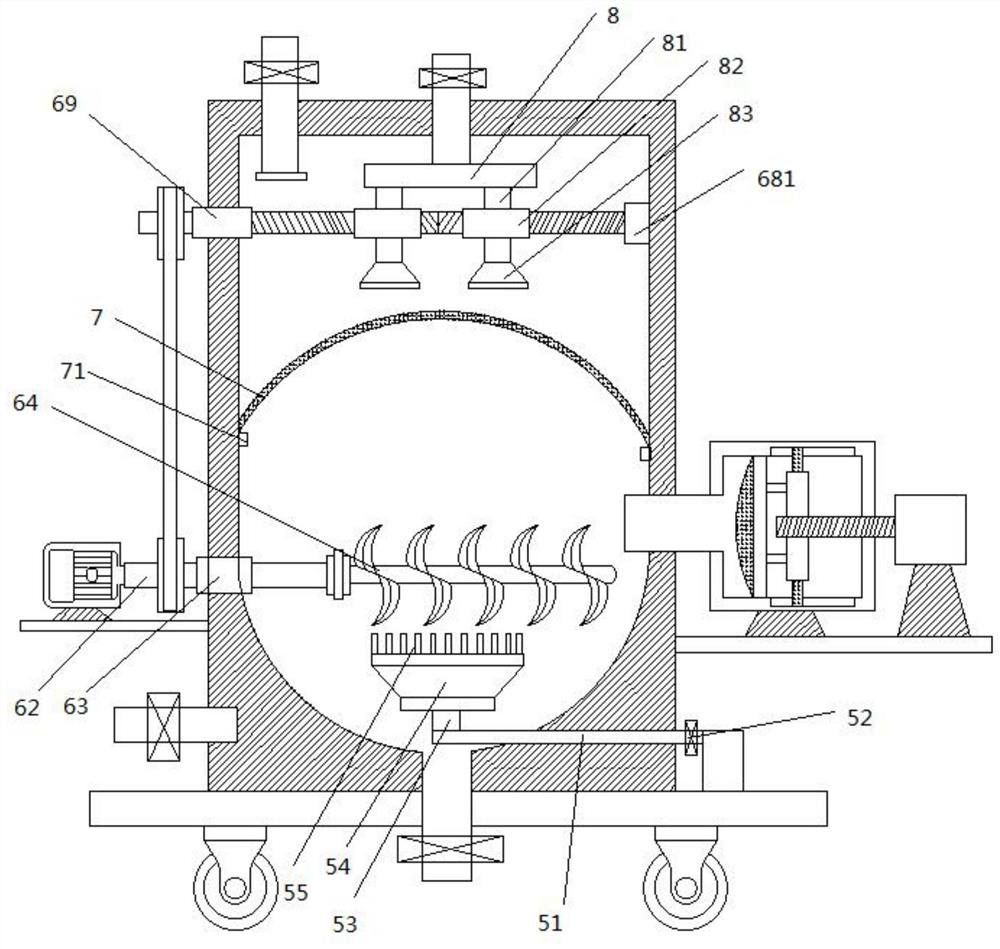

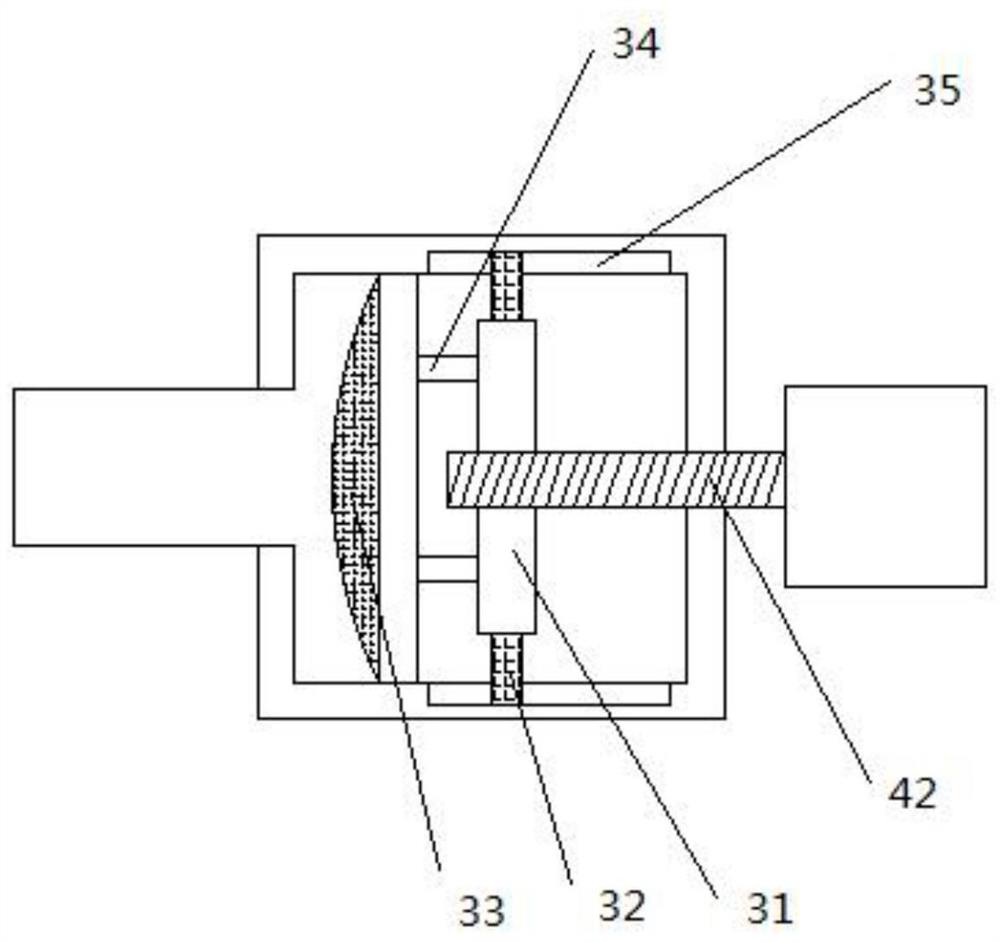

[0032] In the second step, the alkylsulfonyl chloride mixture is dropped into the degasser from the feed pipe 21, and the chlorine, sulfur dioxide and by-product hydrogen chloride gas in the alkylsulfonyl chloride mixture are removed through the degasser to obtain the impurity-removed alkylsulfonyl chloride liquid, and discharge the degasser through discharge pipe 25 to obtain purified alkylsulfonyl chloride;

[0033] The third step is to add the purified alkylsulfonyl chloride into th...

Embodiment 2

[0036] A degassing process for producing sodium cetyl sulfonate, comprising the following steps:

[0037] The first step is to add heavy oil into the reaction kettle, and under the light of ultraviolet light, pass the mixed gas of chlorine gas and sulfur dioxide into the reaction kettle according to the volume ratio of 1:2, control the temperature in the reaction kettle to 33 ℃, and the rotation speed to 150r / min Under the condition, react 4h, obtain alkylsulfonyl chloride mixture;

[0038] In the second step, the alkylsulfonyl chloride mixture is dropped into the degasser from the feed pipe 21, and the chlorine, sulfur dioxide and by-product hydrogen chloride gas in the alkylsulfonyl chloride mixture are removed through the degasser to obtain the impurity-removed alkylsulfonyl chloride liquid, and discharge the degasser through discharge pipe 25 to obtain purified alkylsulfonyl chloride;

[0039] The third step is to add the purified alkylsulfonyl chloride into the reaction ...

Embodiment 3

[0042] A degassing process for producing sodium cetyl sulfonate, comprising the following steps:

[0043] The first step is to add heavy oil into the reaction kettle, and under the light of ultraviolet light, pass the mixed gas of chlorine gas and sulfur dioxide into the reaction kettle according to the volume ratio of 1:2, control the temperature in the reaction kettle to 35 ℃, and the rotation speed to 200r / min Under the following conditions, react for 5h to obtain a mixture of alkylsulfonyl chlorides;

[0044] In the second step, the alkylsulfonyl chloride mixture is dropped into the degasser from the feed pipe 21, and the chlorine, sulfur dioxide and by-product hydrogen chloride gas in the alkylsulfonyl chloride mixture are removed through the degasser to obtain the impurity-removed alkylsulfonyl chloride liquid, and discharge the degasser through discharge pipe 25 to obtain purified alkylsulfonyl chloride;

[0045] The third step is to add the purified alkylsulfonyl chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com