A kind of graphene composite flame retardant material and preparation method thereof

A technology of graphene composite and flame-retardant materials, which is applied in the direction of graphene and nano-carbon, which can solve the problems of large environmental pollution, open flames on the surface of materials that cannot be extinguished quickly, and large amounts of smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

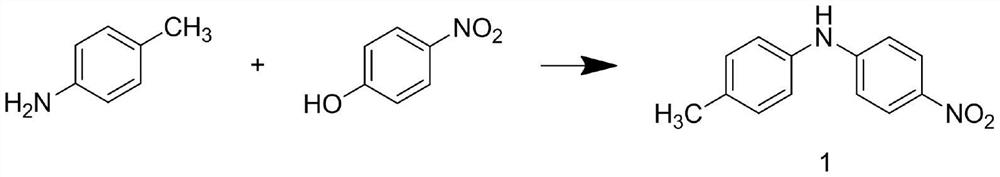

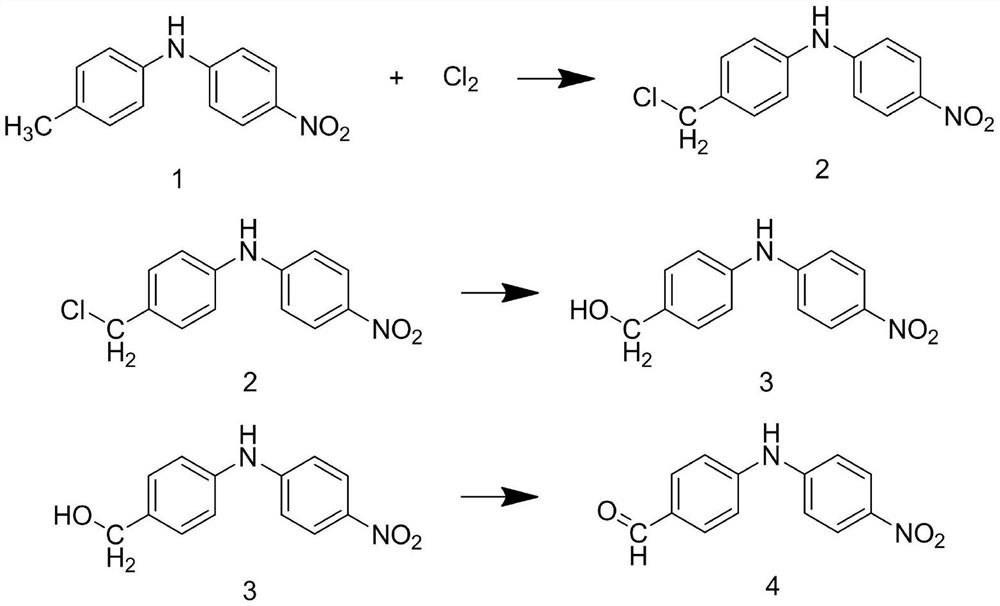

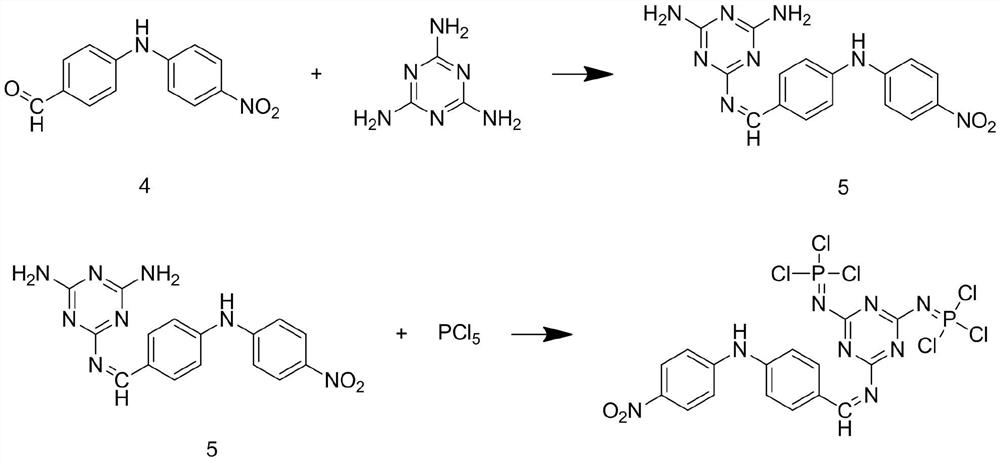

Method used

Image

Examples

Embodiment 1

[0045] A graphene composite flame-retardant material, comprising the following raw materials in parts by weight: 30 parts of modified graphene and 10 parts of flame-retardant additives;

[0046] The graphene composite flame retardant material is made by the following steps:

[0047] Step S1: Add modified graphene and deionized water into the reactor, stir at a speed of 300r / min and a temperature of 35°C, add flame retardant additives and 1-hydroxybenzotriazole, and carry out Stir for 2h to obtain a mixed solution;

[0048] Step S2: Ultrasonicate the mixture obtained in Step S1 at a frequency of 3 MHz for 10 minutes, filter and remove the filtrate, and dry the filter cake at a temperature of 80°C for 2 hours to obtain a graphene composite Flame retardant material.

[0049] Described modified graphene is made by following steps:

[0050] Step A1: Add concentrated sulfuric acid into the reaction kettle, stir at a speed of 150r / min, add graphite and sodium nitrate at a temperat...

Embodiment 2

[0060] A graphene composite flame-retardant material, comprising the following raw materials in parts by weight: 40 parts of modified graphene and 13 parts of flame-retardant additives;

[0061] The graphene composite flame retardant material is made by the following steps:

[0062] Step S1: Add modified graphene and deionized water into the reactor, stir at a speed of 300r / min and a temperature of 40°C, add flame retardant additives and 1-hydroxybenzotriazole, and carry out Stir for 2h to obtain a mixed solution;

[0063] Step S2: Ultrasonicate the mixed liquid obtained in Step S1 at a frequency of 5 MHz for 10 minutes, filter and remove the filtrate, and dry the filter cake at a temperature of 80° C. for 3 hours to obtain a graphene composite Flame retardant material.

[0064] Described modified graphene is made by following steps:

[0065] Step A1: Add concentrated sulfuric acid into the reaction kettle, stir at a speed of 150r / min, add graphite and sodium nitrate at a t...

Embodiment 3

[0075] A graphene composite flame retardant material, comprising the following raw materials in parts by weight: 50 parts of modified graphene and 15 parts of flame retardant additives;

[0076] The graphene composite flame retardant material is made by the following steps:

[0077] Step S1: Add modified graphene and deionized water into the reaction kettle, stir at a speed of 500r / min and a temperature of 40°C, add flame retardant additives and 1-hydroxybenzotriazole, and carry out Stir for 3h to obtain a mixed solution;

[0078] Step S2: Ultrasonicate the mixed liquid obtained in Step S1 at a frequency of 5 MHz for 15 minutes, filter and remove the filtrate, and dry the filter cake at a temperature of 80° C. for 3 hours to obtain a graphene composite Flame retardant material.

[0079] Described modified graphene is made by following steps:

[0080] Step A1: Add concentrated sulfuric acid into the reaction kettle, stir at a speed of 200r / min, add graphite and sodium nitrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com