Polyurethane composition, preparation method and application thereof

A polyurethane and composition technology, applied in the field of polyurethane composition and its preparation, can solve problems such as loss, no reaction sites of flame retardants, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

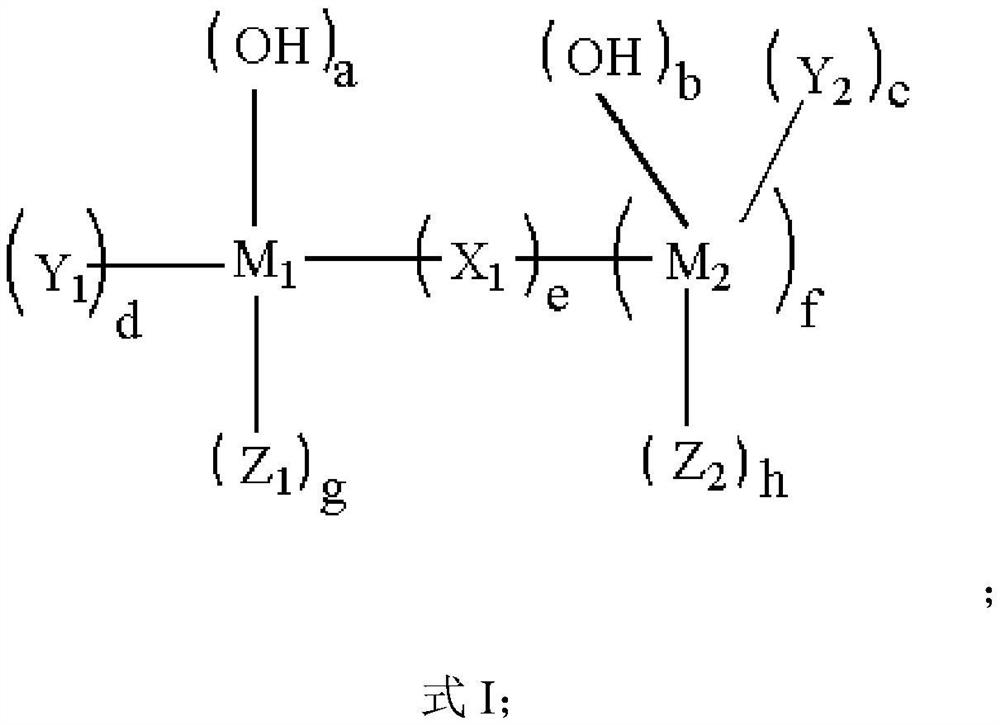

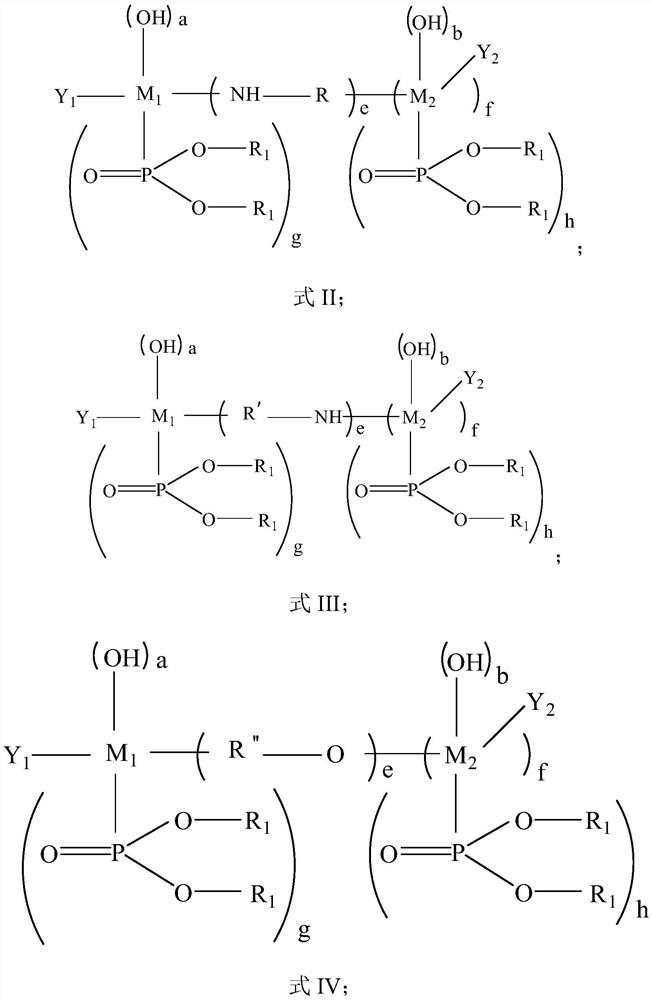

[0085] A phosphorus-containing small molecular alcohol has the following structure:

[0086]

[0087] The preparation method is as follows:

[0088]Add 2 mol of dimethyl phosphite, 1 mol of o-phthalaldehyde, and 20 mL of ethanol into a three-necked flask equipped with magnetic stirring and a thermometer. Under stirring, keep the temperature below 5°C in an ice-water bath, add 2 mol of triethylamine dropwise, gradually Raise the temperature to reflux, continue the reaction for 1 h, and distill under reduced pressure to obtain the reactive flame retardant with the above structure.

[0089] 1 H NMR (400MHz, DMSO-d6): δ=7.10-7.14(s, 4H, ph-H), 4.58-4.62(s, 2H, -CH-P), 3.40-3.45(d, 12H, -P-O- CH 3 ).

preparation example 2

[0091] A phosphorus-containing small molecular alcohol has the following structure:

[0092]

[0093] The preparation method is as follows:

[0094] Add 1 mol of trimethyl phosphate, 2.1 mol of 1,4-benzenediethanol, 0.05 mol of cadmium acetate and 0.05 mol of antimony trioxide into a 200mL three-port glass reactor, heat up to reflux temperature, reflux for 7 hours, filter after cooling, spin Methanol was evaporated to give the product.

[0095] 1 H NMR (400MHz, DMSO-d6): δ=7.02-7.16(m,8H,-Ph),4.29-4.41(m,4H,-P-O-C H 2 -),4.00-4.04(t,2H,-OH),3.73-3.85(m,4H,-C H 2 -OH),3.44-3.48(d,3H,-P-O-CH 3 ),2.92-2.96(m,4H,-P-O-CH 2 -C H 2 -),2.73-2.83(m,4H,-C H 2 -CH 2 -OH).

preparation example 3

[0097] A phosphorus-containing small molecular alcohol has the following structure:

[0098]

[0099] The preparation method is as follows:

[0100] Add 1 mol of triphenyl phosphate, 2.1 mol of 1,4-benzenediethanol, 0.05 mol of cadmium acetate and 0.05 mol of antimony trioxide into a 200mL three-port glass reactor, heat up to reflux temperature, reflux for 10 hours, filter after cooling, reduce The benzyl alcohol was removed by distillation to obtain the product.

[0101] 1 H NMR (400MHz, DMSO-d6): δ=7.03-7.28(m,13H,-Ph),4.30-4.40(m,4H,-P-O-C H 2 -),4.23-4.26(t,2H,-OH),3.76-3.87(m,4H,-C H 2 -OH),2.93-2.97(m,4H,-P-O-CH 2 -C H 2 -),2.76-2.84(m,4H,-C H 2 -CH 2 -OH).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com