Pouring sealant and preparation method thereof

A technology of potting glue and spherical alumina, which is applied in adhesives, photovoltaic power generation, adhesive additives, etc., can solve the problems of inability to conduct heat out of the junction box, low thermal conductivity of potting glue, damage to photovoltaic modules, etc., and achieve low cost , high thermal conductivity, and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

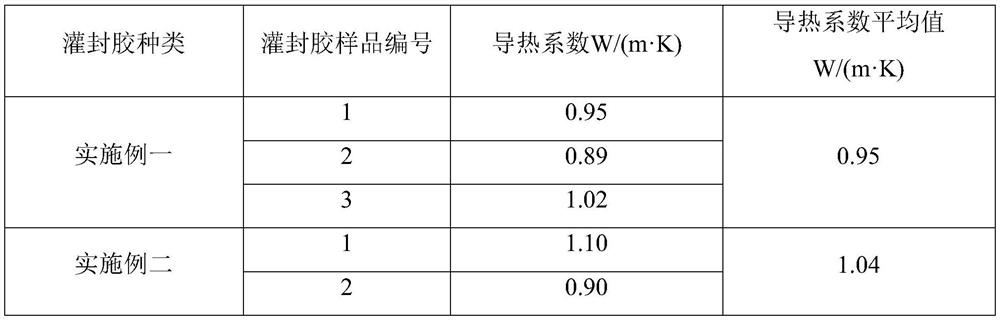

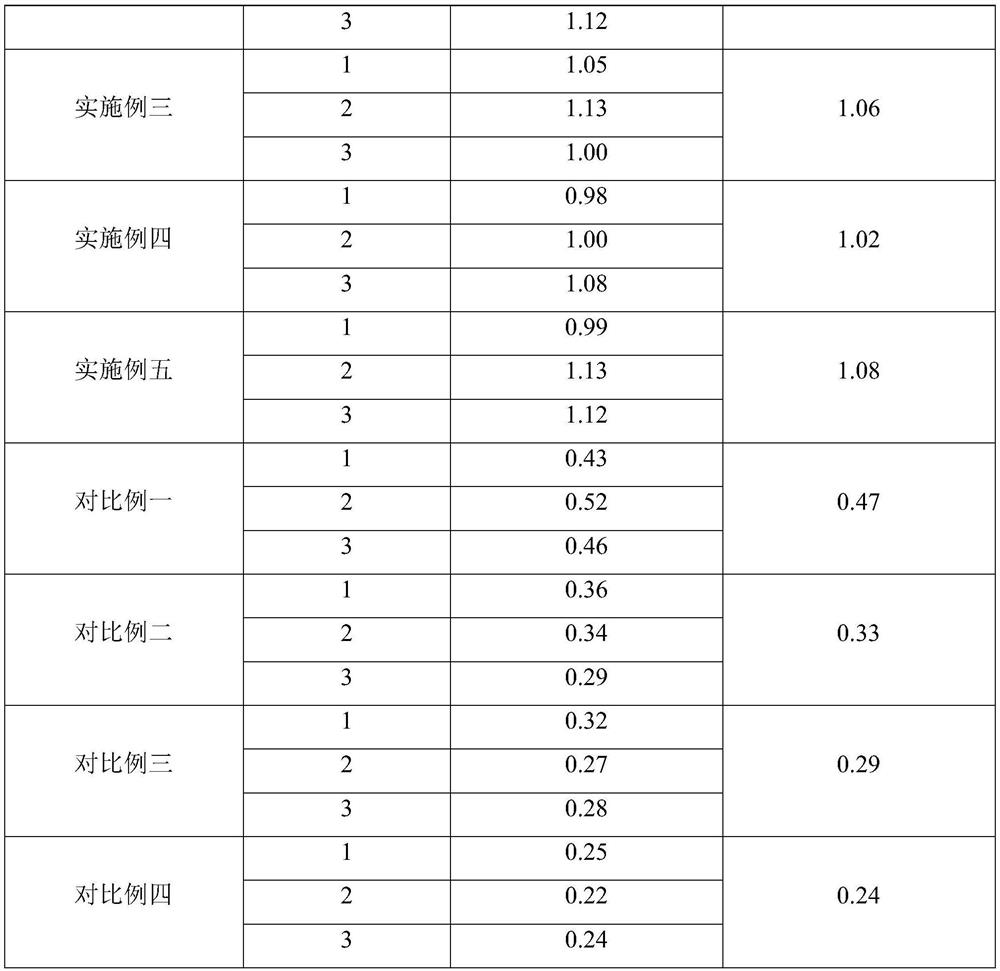

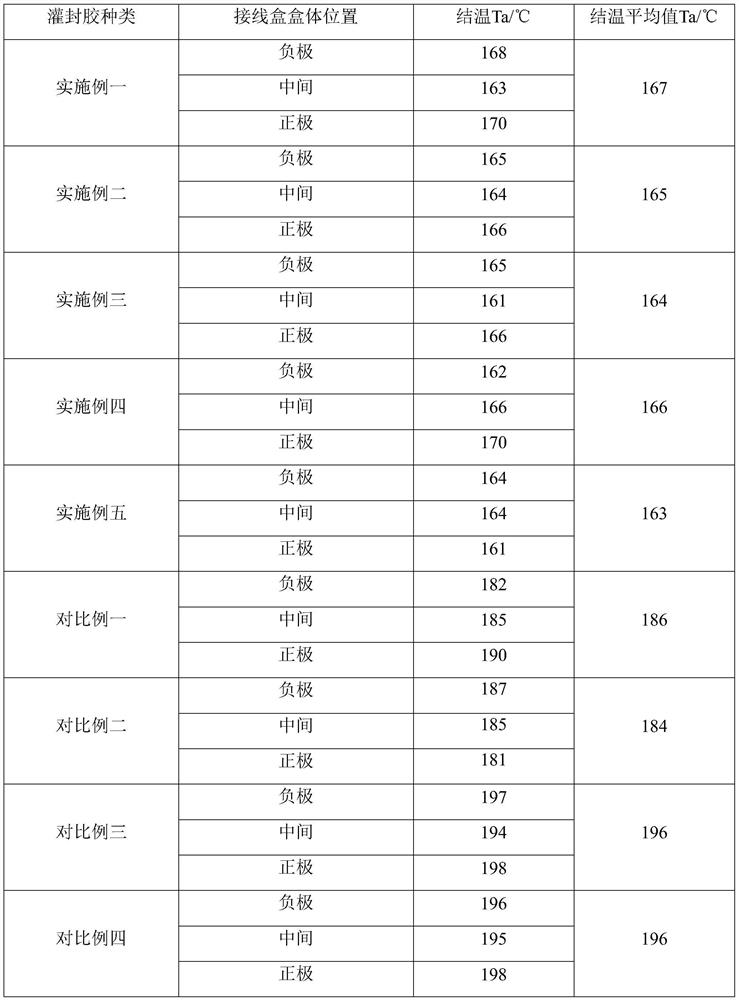

Examples

preparation example Construction

[0046] The embodiment of the present invention also provides a method for preparing the potting compound, which is used to prepare the potting compound provided in the above embodiment. The preparation method of this encapsulant comprises:

[0047]Step 1, mixing white carbon black, first spherical alumina and second spherical alumina to obtain powder filler. The equipment used for mixing can be a high-speed mixer, and the mixing speed can be 500r / min-700r / min. At this time, powders of three different particle sizes can be fully mixed to avoid agglomeration. The mixing speed can be 500r / min, 600r / min, 650r / min or 700r / min, etc.

[0048] Step 2, mixing the powder filler and the organopolysiloxane polymer to obtain the base material.

[0049] Step 3, mixing base material, organometallic catalyst and plasticizer to obtain potting compound. It should be understood that in practical applications, the metal organotin catalyst and the plasticizer can be added to the base material ...

Embodiment 1

[0053] In parts by mass, the encapsulant provided in this embodiment includes: 100 parts of organopolysiloxane polymer, 30 parts of white carbon black of 10nm-15nm, 15 parts of the first spherical alumina with a particle size of 50um-60um , 10 parts of second spherical alumina with a particle size of 5um to 10um, 2 parts of organotin catalyst and 1 part of plasticizer. The organopolysiloxane polymer is a mixture of hydroxyl-terminated polydimethylsiloxane, alkoxy-terminated polydimethylsiloxane, and alkyl-terminated polydimethylsiloxane. The organotin catalyst is a mixture of dibutyltin dilaurate, dioctyltin dilaurate and dibutyltin diacetate. The plasticizer is a mixture of diisononyl phthalate, diethyl phthalate and diisobutyl phthalate. The preparation method of the potting glue of the present embodiment specifically comprises the following steps:

[0054] In the first step, the white carbon black, the first spherical alumina and the second spherical alumina are mixed in ...

Embodiment 2

[0059] In terms of parts by mass, the encapsulant provided in this embodiment includes: 100 parts of organopolysiloxane polymer, 50 parts of white carbon black of 15nm-20nm, 10 parts of the first spherical alumina with a particle size of 60um-80um , 20 parts of the second spherical alumina with a particle size of 10um to 15um, 2 parts of organic tin catalyst and 1 part of plasticizer. The organopolysiloxane polymer is hydroxyl terminated polydimethylsiloxane. The organotin catalyst is dibutyltin dilaurate. The plasticizer is diisononyl phthalate. The preparation method of the potting glue of the present embodiment specifically includes the following steps

[0060] In the first step, the white carbon black, the first spherical alumina and the second spherical alumina are mixed in a high-speed mixer at a mixing speed of 500 r / min to obtain a powder filler.

[0061] The second step is to mix the powder filler and organopolysiloxane polymer to obtain the base material.

[0062...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com