Mineral processing method for efficiently recycling iron blast furnace ash

A technology of recycling and beneficiation methods, which is applied in the direction of furnaces, rotary drum furnaces, furnace types, etc., can solve the problems of insufficient environmental protection, inability to efficiently and comprehensively recover iron, zinc, and slag, and reduce the pressure on environmental protection , High resource recycling rate, good beneficiation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

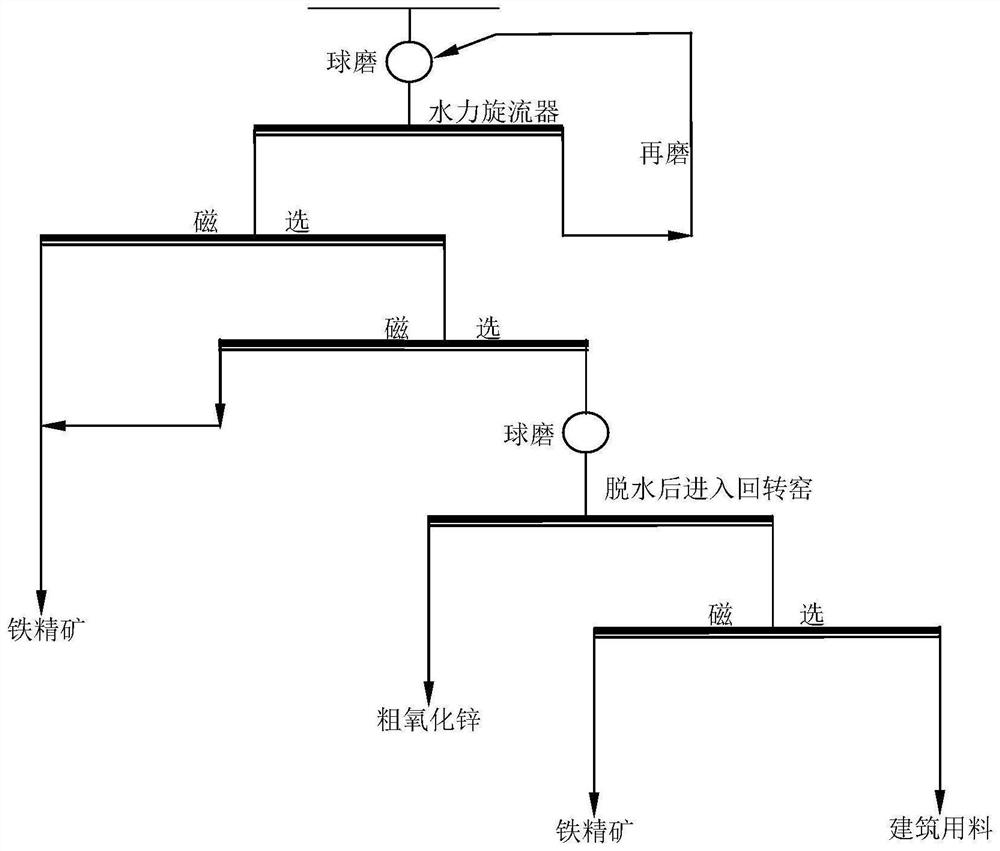

[0028] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0029] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

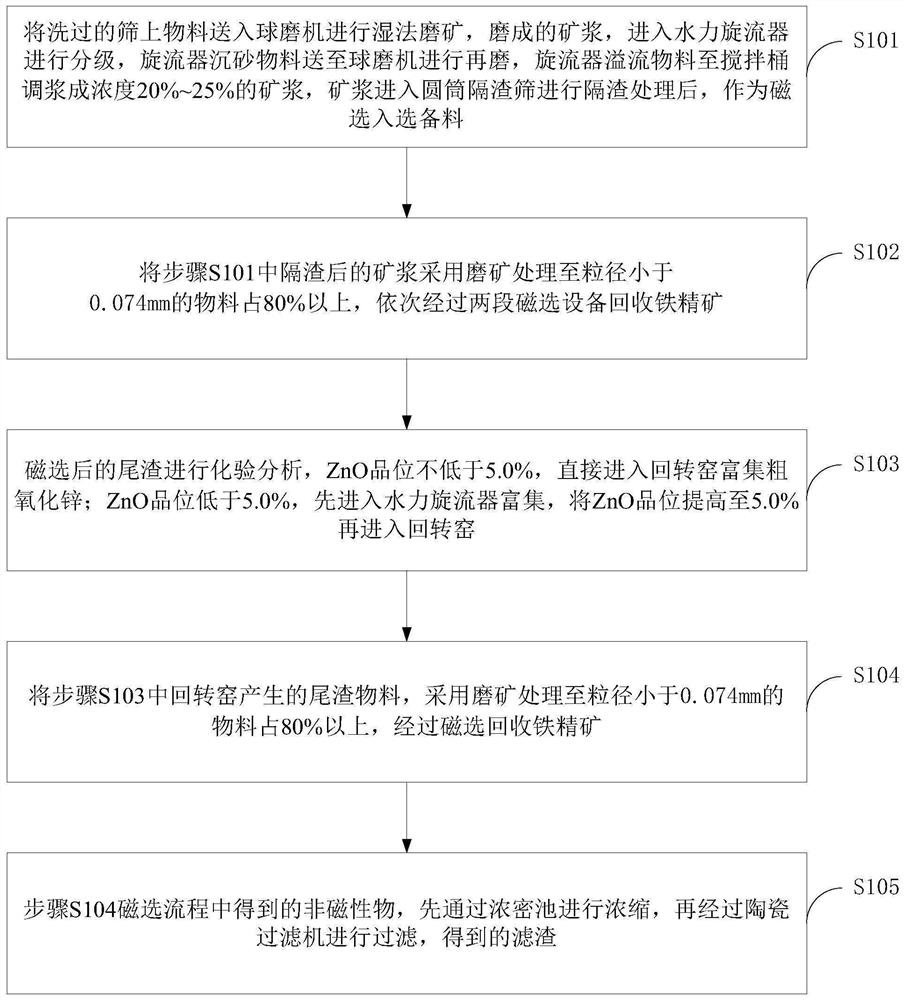

[0030] A beneficiation method for efficient iron blast furnace ash recycling and utilization, the specific steps are as follows:

[0031] S101. Send the washed sieve material into the ball mill for wet grinding, and the ground slurry enters the hydrocyclone for classification, and the sand settling material of the cyclone is sent to the ball mill for regrinding, and the overflow material of the cyclone After the mixing tank is adjusted to a pulp with a concentration of 20% to 25%, the pulp enters the cylindrical slag separation screen for slag separation treatment, and is used as magnetic separation for selection and preparation;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com