Preparation method of modified molecular sieve catalyst and method for continuously synthesizing 3-methoxy-3-methyl butanol

A technology of molecular sieve and catalyst, which is applied in the synthesis field of 3-methoxy-3-methylbutanol, an important fine chemical raw material, can solve the problems of long reaction time, coking of catalyst, slow reaction rate, etc., and achieve the reduction of light components and high polymer formation, improved service life and stability, reliable and stable operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

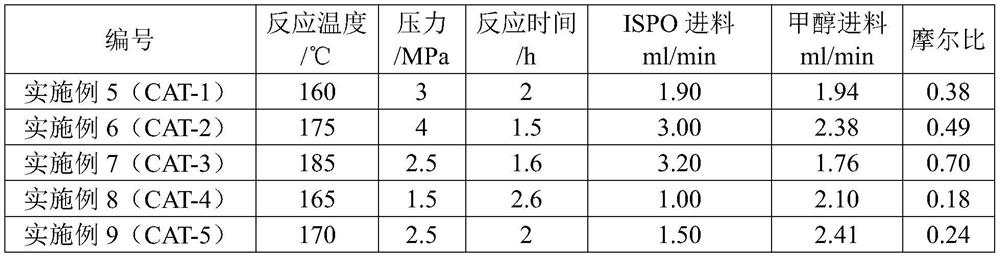

[0037] Add 50g of bentonite to 116g of pure water and stir evenly to form slurry A; dissolve 30g of sodium tripolyphosphate in 90g of water and stir evenly to form solution B; add 400g of nano aluminum sol and 41.6g of solution B to slurry A, Stir for 1.5h to obtain uniformly mixed slurry C; add 750g of USY molecular sieve to slurry C, stir for 2h, put it in an oven at 80°C after stirring evenly, evaporate and remove excess water, and obtain a semi-finished catalyst ; The semi-finished catalyst was extruded into a spherical shape, washed with ethanol, sent to an oven for drying, and then transferred to a muffle furnace for calcination at 700°C for 3 hours to obtain the finished spherical catalyst CAT-1.

Embodiment 2

[0039] Add 60g of bentonite to 73.3g of pure water and stir evenly to form slurry A; dissolve 40g of sodium hexametaphosphate in 74.3g of water and stir evenly to form solution B; add 373.3g of nano aluminum sol and 26.7g of Solution B, stirred for 2 hours to obtain uniformly mixed slurry C; add 799.5g of NaY molecular sieve to slurry C, stirred for 2.5 hours, put it into an oven at 85°C after stirring, and evaporated the excess water , to obtain a semi-finished catalyst; the semi-finished catalyst was extruded into a spherical shape, washed with ethanol, sent to an oven for drying, and then transferred to a muffle furnace for calcination at 650°C for 2.5 hours to obtain a finished spherical catalyst CAT-2.

Embodiment 3

[0041]Add 45g of bentonite to 36.82g of pure water and stir evenly to form slurry A; dissolve 52g of disodium dihydrogen pyrophosphate in 63.6g of water and stir evenly to form solution B; add 210g of nano aluminum sol and 11.68 g solution B, stirred for 1.2h to obtain uniformly mixed slurry C; added 575.7g of 5A molecular sieve to slurry C, stirred for 2.2h, put it in an oven at 85°C after stirring evenly, and evaporated the excess water Removed to obtain a semi-finished catalyst; the semi-finished catalyst was extruded into a spherical shape, washed with ethanol, dried in an oven, and then transferred to a muffle furnace for 3.5 hours at 680°C to obtain a finished spherical catalyst CAT-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com