Copper-based CHA type aluminosilicate molecular sieve catalyst and preparation method thereof

A silicon-alumina molecular sieve and catalyst technology, which is applied in molecular sieve catalysts, catalyst activation/preparation, molecular sieves and alkali exchange compounds, etc., can solve the problems of large amount of template agent and increased preparation cost, and can reduce the amount and meet the temperature window of reaction activity. Wider requirements and the effect of saving raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

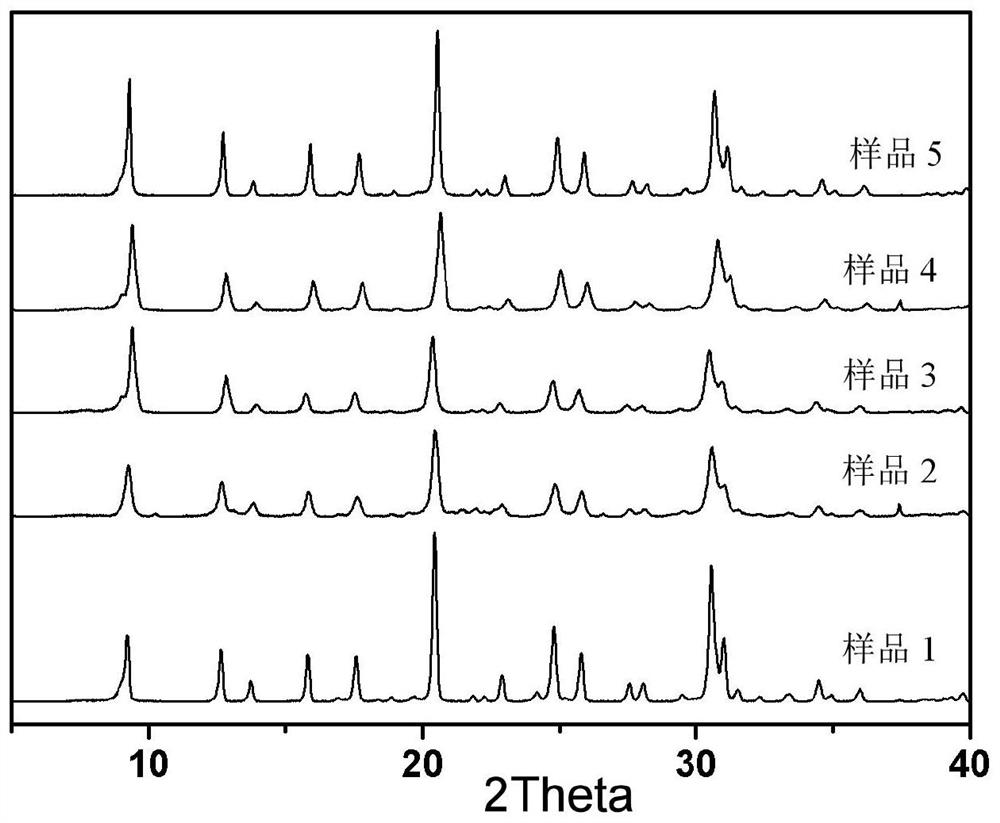

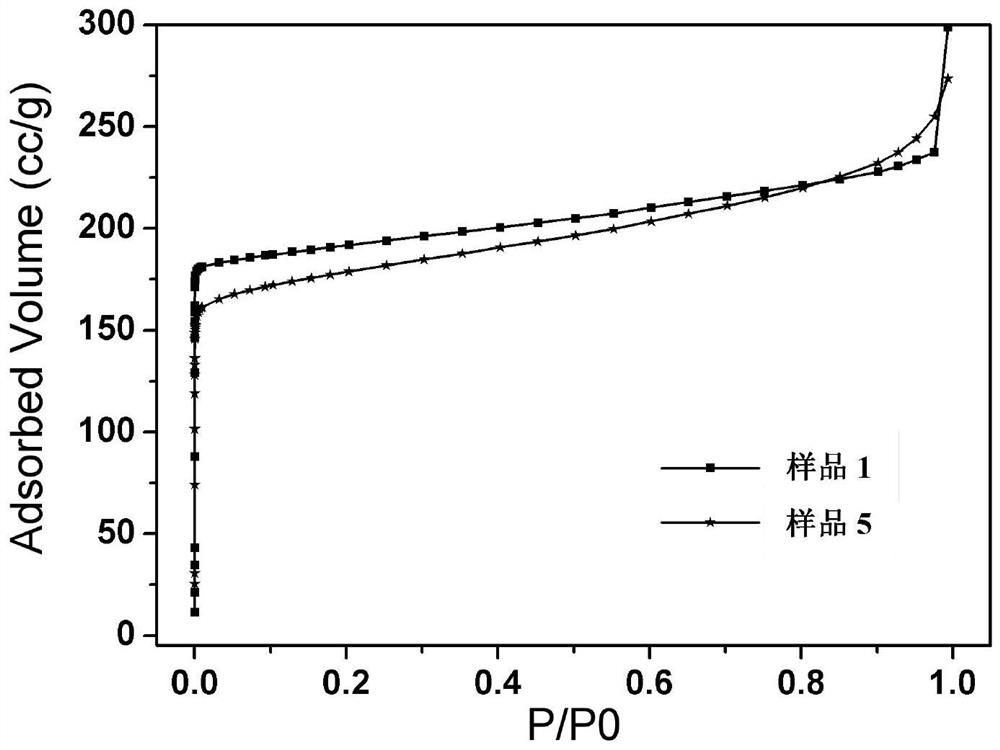

[0041] 0.5 g of SSZ-13 silicone aluminum aluminum aluminum aluminum aluminum ratio 20 was added to 30 g of water, and the stirred was uniform, then 0.2 g of 0.2 g of the mixture. 4 F, mixed with a magnetic stirrer at 50 ° C for 12 hours, and the mother liquor was separated from the product by filtration, and the product was washed with deionized water. As a seed crystal.

[0042] Under the conditions of stirring, 23 g of 40% silica sol, 46 g of water, 1.47 gal (OH) were sequentially 3 , 5.98 g 20% of the diamondae, 3.54 g of tetramethylammonium hydroxide was added to a 150 ml reactor with 1.3 g NaOH, and the seed crystals were added for 6 hours, continued to be agitation conditions for 16 h, then heated to 160 ° C. The crystallization was 60 h, and the mixture was removed, and the product was placed in an oven at 110 ° C for 6 h, then calcined at 600 ° C for 2 h to obtain a Na type CHA molecular sieve.

[0043] 0.5mol / lnh 4 The CL solution was mixed with the above-described Na...

Embodiment 2

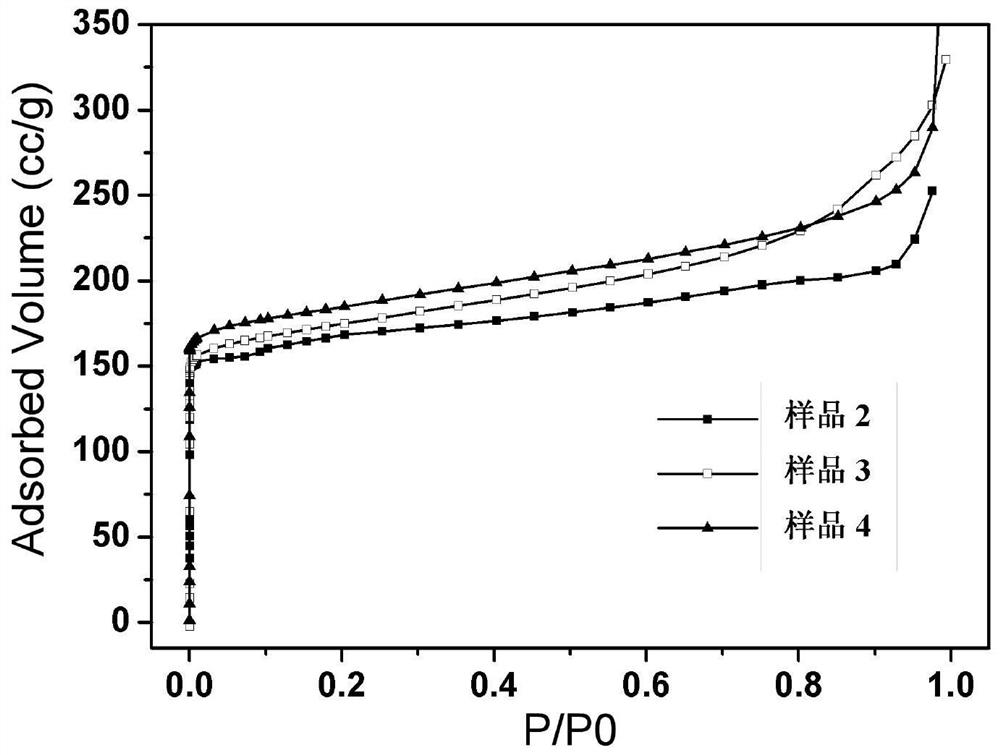

[0047] The Y molecular sieve 1 g of the silicon aluminum aluminum aluminum aluminum ratio 10 was added to 30 g of water, and the stirred was uniform, then 0.3 g of NH was added to the mixture. 4 F, mixed with a magnetic stirrer for 5 hours at 40 ° C, and the mother liquor was separated from the product by filtration, and the product was washed with deionized water to be used as a seed crystal.

[0048] Under the conditions of stirring, 23 g of 40% silica sol, 46 g of water, 1.47 gal (OH) were sequentially 3 6.83 g 20% of the diamondane, 3.54 g of 4% tetramethylammonium hydroxide was added to a 150 mL reactor with 1.3 g NaOH, and the seed crystals were added for 6 hours, continued to be agitation conditions for 16 h, then heated to 160 ° C. The crystallization 72h was removed from the mixture, and the product was placed in an oven at 110 ° C for 6 h at an oven at 110 ° C for 2 h, followed by a deionized water, and then calcined at 600 ° C to obtain a Na type CHA molecular sieve. ...

Embodiment 3

[0052] The Y molecular sieve 1 g of the silicon aluminum aluminum ratio 15 was added to 30 g of water, and the stirred was uniform, then 0.8 g of NH was added to the mixture. 4 F, mixed with a magnetic stirrer for 4 hours at 50 ° C, separated from the product by filtration, and the product was washed with deionized water. As seeded.

[0053] The rest is the same as in Example 2.

[0054] Marked as sample 3, SiO 2 / Al 2 O 3 = 15.3, specific surface area 550m 2 / g, the average aperture is 0.5 nm, and the Cu content is 3.38 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com