Preparation method of strontium titanate with adjustable strontium vacancy and application of strontium titanate in field of photocatalytic hydrogen production

A strontium titanate and photocatalytic technology, which is applied in the direction of titanate, titanium compounds, chemical instruments and methods, etc., can solve the problems of hindered application of photocatalytic technology, insufficient utilization of solar energy and recombination rate, and achieve less impurities, low cost, Good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

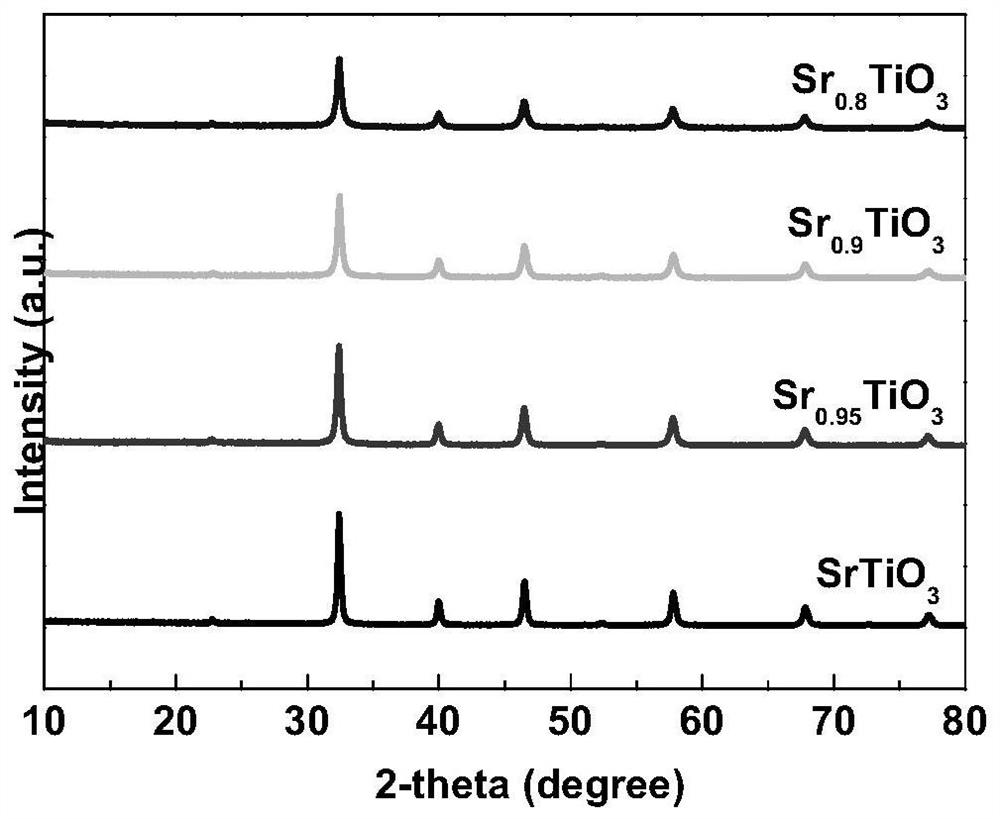

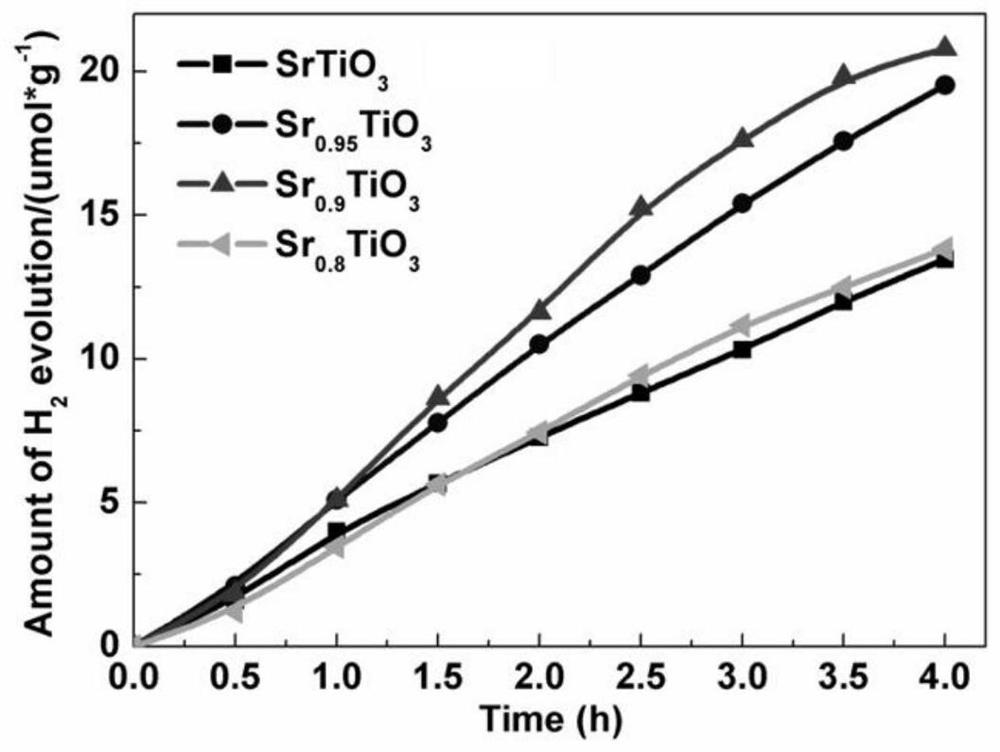

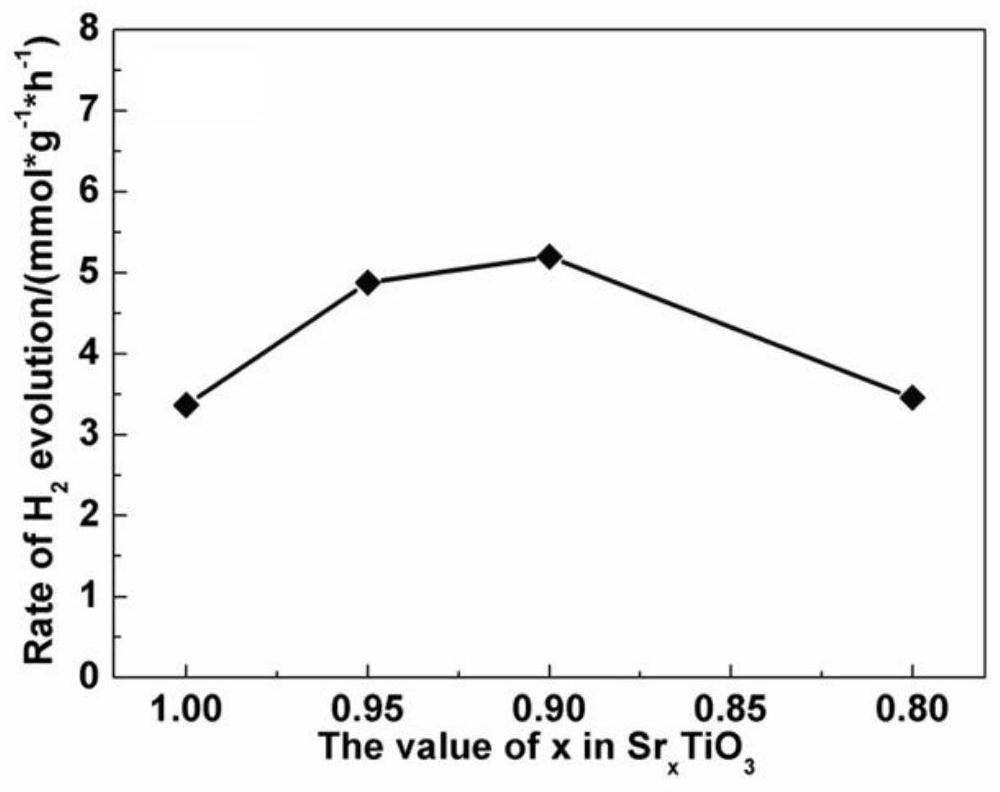

[0017] Example 1: Stir and dissolve 0.15 mol of citric acid and 35 ml of deionized water at room temperature, quickly add 0.05 mol of tetrabutyl titanate to the aqueous solution of citric acid, stir and dissolve on a thermal magnetic stirrer at 90°C until clear ; Add 0.045mol strontium acetate to the dissolved solution, add 34ml ethylene glycol after the strontium acetate is dissolved, and stir for 2 hours at 120°C on a thermal magnetic stirrer; place the solution in a porcelain crucible, cover the crucible, and send it into In the muffle furnace, set the heating conditions: the heating rate is 10°C / min, the constant temperature is 350°C for 1h, and after natural cooling, it is fully ground to obtain the strontium titanate photocatalyst precursor powder; take 4g of the strontium titanate precursor and place it in a porcelain crucible. Send it into a muffle furnace for high-temperature sintering, set the heating conditions: heating rate 10 ° C / min, 700 ° C constant temperature...

Embodiment 2

[0018] Embodiment 2: difference with embodiment 1 is: the strontium acetate content that adds is 0.040mol, makes strontium titanate sample (Sr 0.8 TiO 3 ).

Embodiment 3

[0019] Embodiment 3: difference with embodiment 2 is: the strontium acetate content that adds is 0.0475mol, makes pure strontium titanate sample (Sr 0.95 TiO 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com