A kind of phenolic resin-acrylamide composite microsphere and its preparation method and application

A technology of acrylamide and composite microspheres, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor stability and unusable oil reservoirs, achieve good thermal stability and swelling, and expand crude oil resources Utilization range, effect of improving water flooding efficiency and crude oil recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a preparation method of phenolic resin-acrylamide composite microspheres, which comprises the following steps:

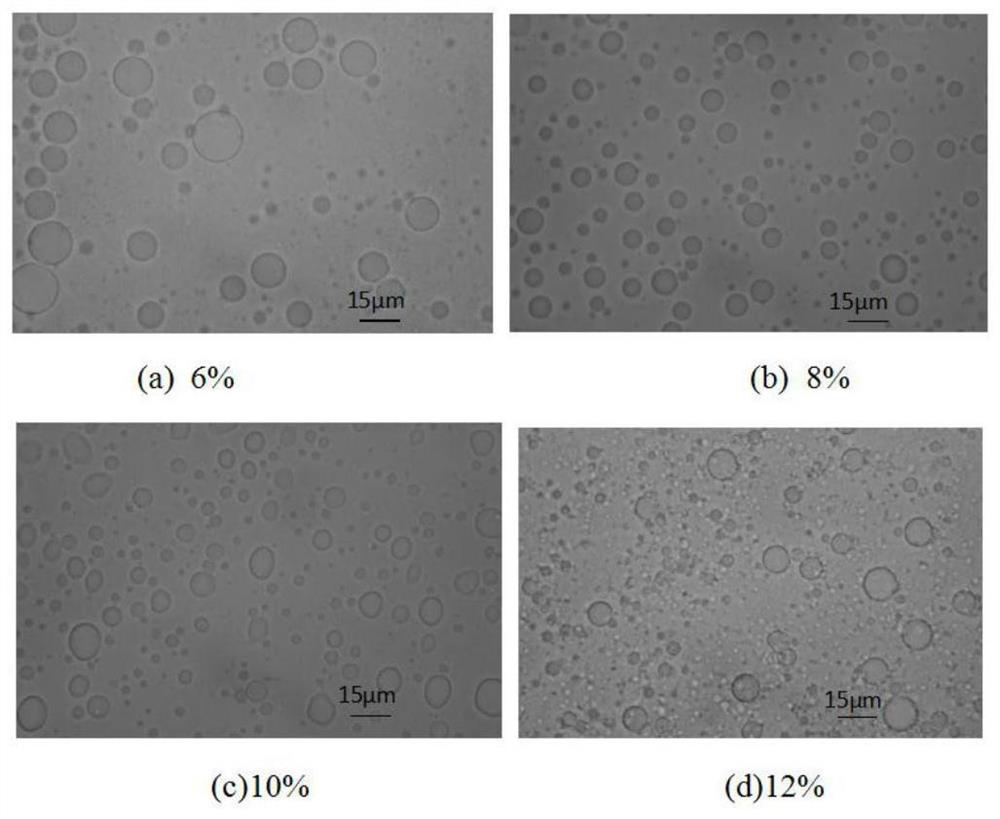

[0041] S1, the Span 80 (Span80) and the Tween 80 (Tween80) composite emulsifier with an HLB value of 5 are placed in white oil and stirred with a magnetic stirrer until clear and transparent to obtain an oil phase to obtain an oil phase, wherein, Span 80 and The mass of the Tween 80 complex emulsifier is 8% of the total mass of the oil phase.

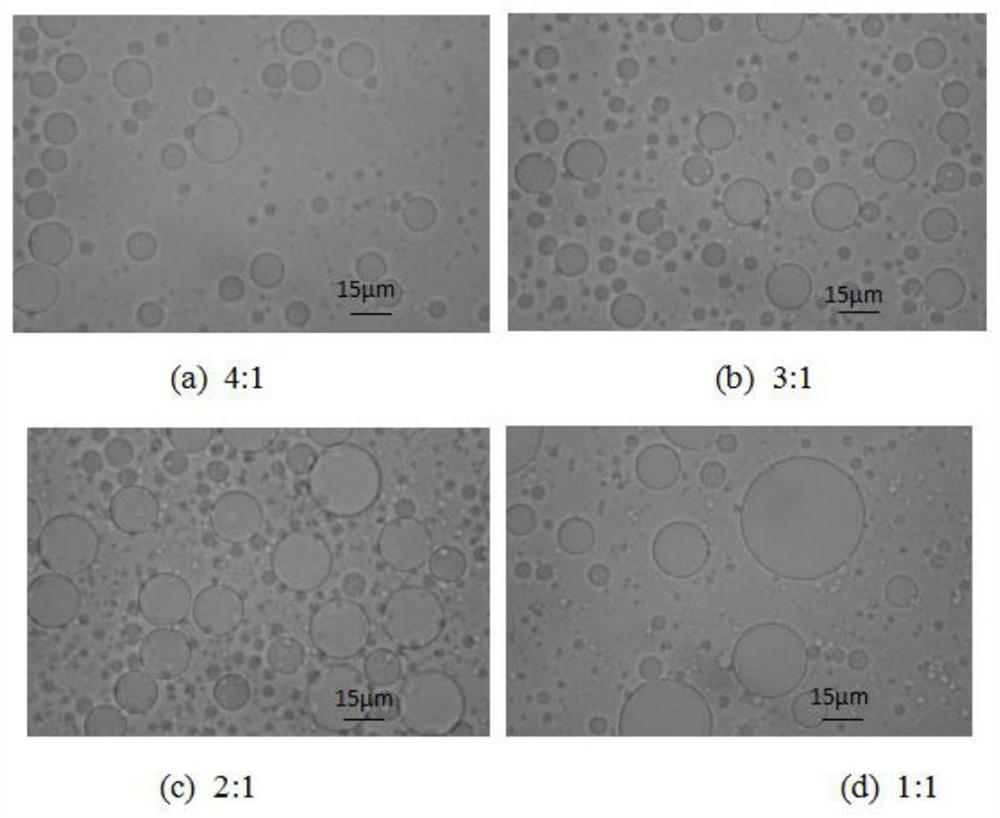

[0042] S2. Dissolve acrylamide (AM), water-soluble phenolic resin (PF), potassium persulfate (KPS), N,N'-methylenebisacrylamide (NMBA) in an appropriate amount of water, and add hydrochloric acid (10% , w / w) adjust pH, obtain the water phase that pH value is 5.01; Wherein, the mass ratio of water phase and oil phase is 1:2; In addition, the mass ratio of acrylamide and water-soluble phenolic resin is 5:3; The mass of potassium sulfate is 0.1% of acrylamide; the mass of N'-methylenebisacrylamid...

Embodiment 2

[0045] This embodiment provides a preparation method of phenolic resin-acrylamide composite microspheres, which comprises the following steps:

[0046] S1, the Span 80 (Span80) and the Tween 80 (Tween80) composite emulsifier with an HLB value of 4 are placed in white oil and stirred with a magnetic stirrer until clear and transparent to obtain an oil phase and obtain an oil phase, wherein, Span 80 and The mass of the Tween 80 complex emulsifier is 7% of the total mass of the oil phase.

[0047] S2. Dissolve acrylamide, water-soluble phenolic resin, potassium persulfate, N,N'-methylenebisacrylamide in an appropriate amount of water, and add hydrochloric acid (10%, w / w) to adjust the pH to obtain a pH value of The water phase of 3; wherein, the mass ratio of the water phase to the oil phase is 1:1.5; in addition, the mass ratio of acrylamide and water-soluble phenolic resin is 4:4; the mass of potassium persulfate is 0.05% of acrylamide, N The mass of '-methylenebisacrylamide i...

Embodiment 3

[0050] This embodiment provides a preparation method of phenolic resin-acrylamide composite microspheres, which comprises the following steps:

[0051] S1, the Span 80 (Span80) and the Tween 80 (Tween80) composite emulsifier with an HLB value of 6 are placed in white oil and stirred with a magnetic stirrer until clear and transparent to obtain an oil phase to obtain an oil phase, wherein, Span 80 and The mass of the Tween 80 complex emulsifier is 9% of the total mass of the oil phase.

[0052] S2. Dissolve acrylamide, water-soluble phenolic resin, potassium persulfate, N,N'-methylenebisacrylamide in an appropriate amount of water, and add hydrochloric acid (10%, w / w) to adjust the pH to obtain a pH value of The water phase of 5.5; wherein, the mass ratio of the water phase to the oil phase is 1:2.5; in addition, the mass ratio of acrylamide and water-soluble phenolic resin is 6:2; the mass of potassium persulfate is 0.3% of acrylamide, N The mass of '-methylenebisacrylamide i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com