Flame-retardant polyurethane nano-cellulose reinforced material and preparation method thereof

A technology of nano-cellulose and reinforcing materials, which is applied in the field of flame-retardant materials, can solve problems such as endangering property and life safety, reducing thermal insulation effect, and poor high-temperature resistance, and achieves the effects of low cost, reduced production cost, and improved flame-retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

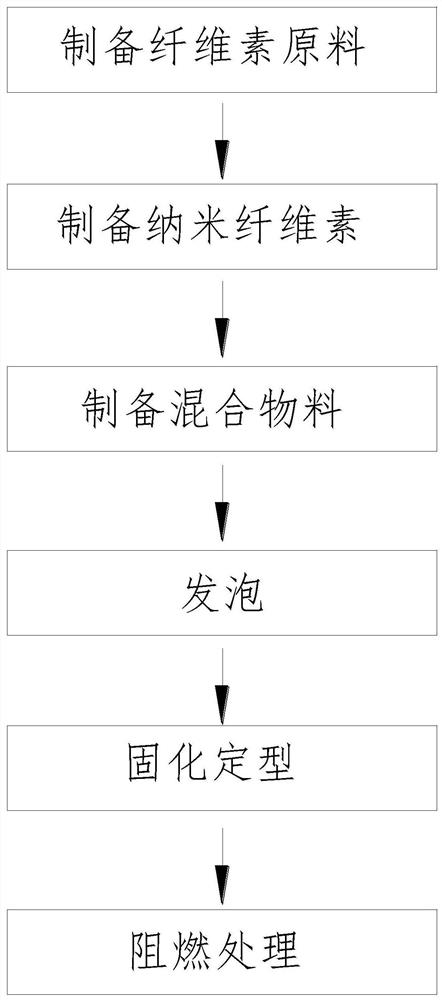

Method used

Image

Examples

Embodiment 1

[0028] A flame-retardant polyurethane nano-cellulose reinforcement material, in parts by weight, the formula includes isocyanate raw materials: 60-80 parts, oligomer polyol raw materials: 80-120 parts, foaming agent: 20-35 parts, uniform Foaming agent: 2-3 parts, initiator: 3-5 parts, chain extender: 2-4 parts, cross-chaining agent: 1-3 parts, plant material: 10-15 parts, epoxy resin 5-10 parts, 8-13 parts of inorganic flame retardant, 25-30 parts of flame-retardant filler, 5-6 parts of compounding agent.

[0029] Specifically, the isocyanate raw material is a mixture of toluene diisocyanate, diphenylmethane diisocyanate and dicyclohexylmethane diisocyanate, the mass ratio of the toluene diisocyanate, diphenylmethane diisocyanate and dicyclohexylmethane diisocyanate It is 2.5:3:1.5.

[0030] Specifically, the oligomer polyol raw material is a mixture of polyester polyol and polyether polyol, and the mass ratio of polyester polyol to polyether polyol is 1:2.

[0031] Specific...

Embodiment 2

[0046] A flame-retardant polyurethane nano-cellulose reinforcement material, in parts by weight, the formula includes isocyanate raw materials: 60-80 parts, oligomer polyol raw materials: 80-120 parts, foaming agent: 20-35 parts, uniform Foaming agent: 2-3 parts, initiator: 3-5 parts, chain extender: 2-4 parts, cross-chaining agent: 1-3 parts, plant material: 10-15 parts, epoxy resin 5-10 parts, 8-13 parts of inorganic flame retardant, 25-30 parts of flame-retardant filler, 5-6 parts of compounding agent.

[0047] Specifically, the isocyanate raw material is a mixture of toluene diisocyanate, diphenylmethane diisocyanate and dicyclohexylmethane diisocyanate, the mass ratio of the toluene diisocyanate, diphenylmethane diisocyanate and dicyclohexylmethane diisocyanate It is 2.5:3:1.5.

[0048] Specifically, the oligomer polyol raw material is a mixture of polyester polyol and polyether polyol, and the mass ratio of polyester polyol to polyether polyol is 1:2.

[0049] Specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com