Durable composite material tray and production method thereof

A composite material and durable technology, which is applied in the field of durable composite material pallets and its production, can solve the problems of poor physical and chemical properties, poor mechanical properties such as structural strength and toughness, and intolerance to use, so as to achieve excellent mechanical properties, The effect of fully integrating and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

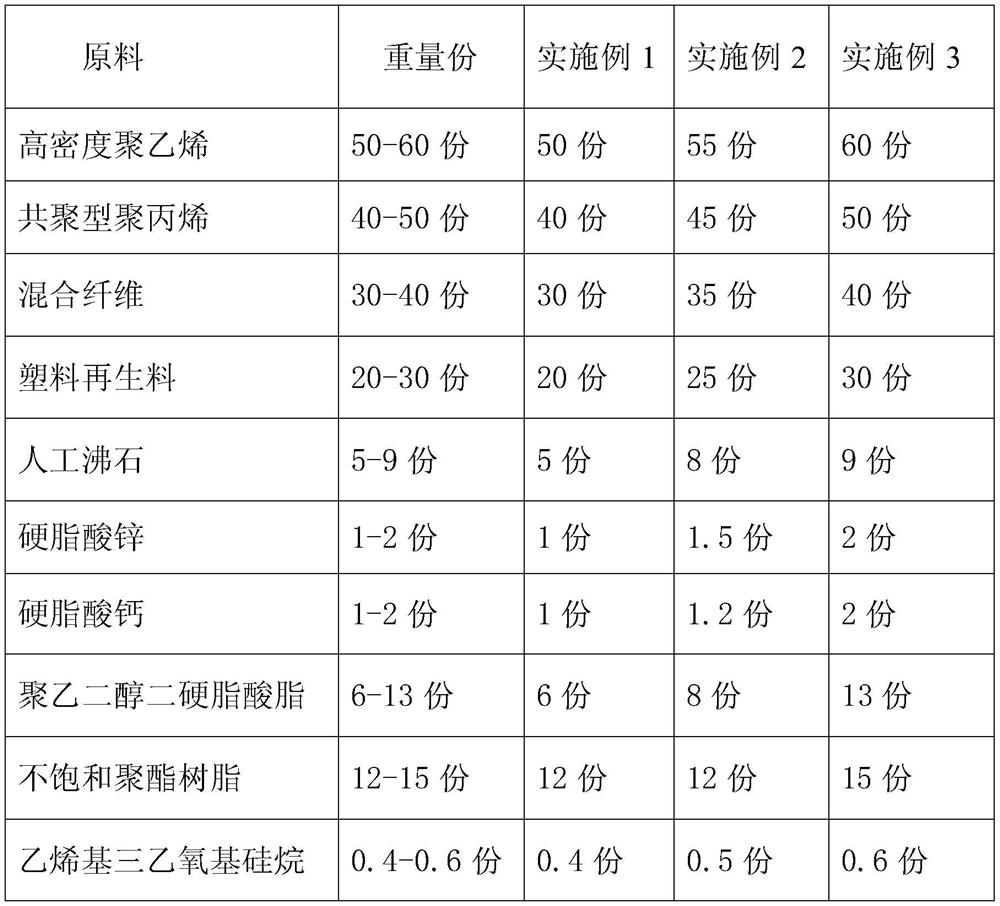

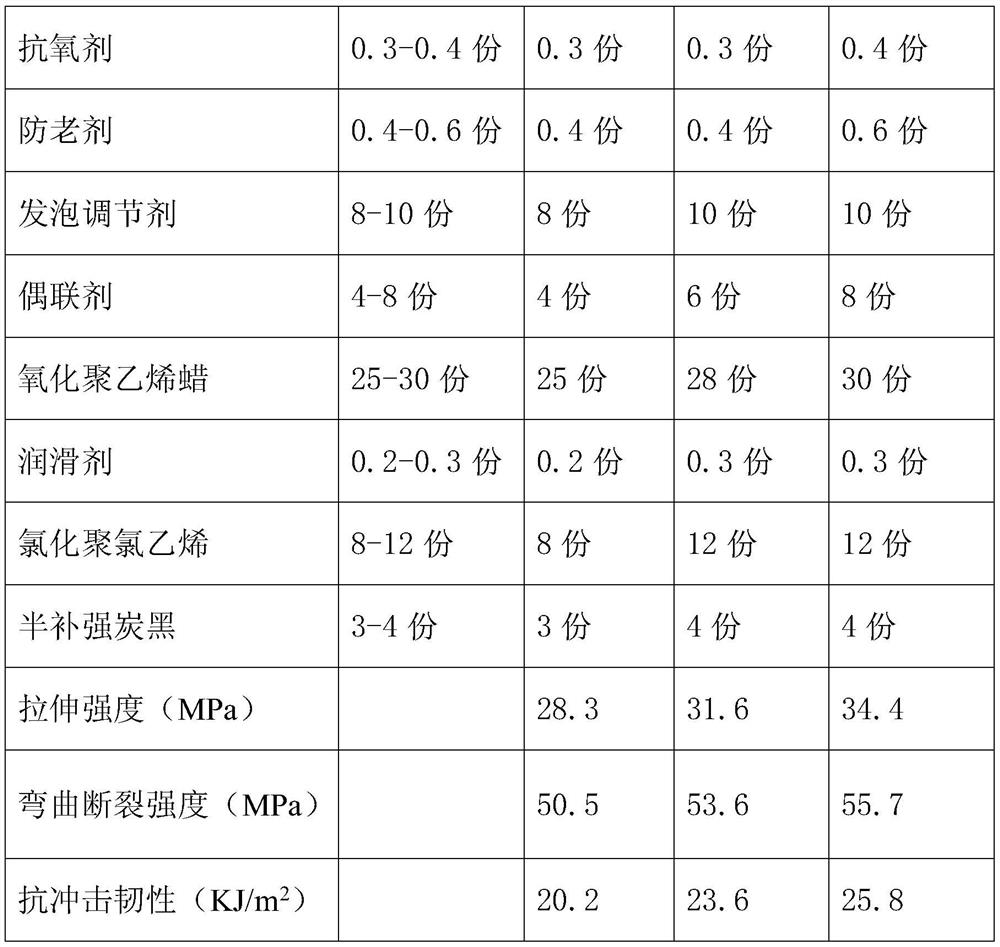

[0016] Embodiment 1: A kind of durable composite material pallet, its raw material is as follows by weight: 50 parts of high-density polyethylene, 40 parts of copolymerized polypropylene, 30 parts of mixed fiber, 20 parts of plastic recycled materials, 5 parts of artificial zeolite , 1 part of zinc stearate, 1 part of calcium stearate, 6 parts of polyethylene glycol distearate, 12 parts of unsaturated polyester resin, 0.4 part of vinyl triethoxysilane, 0.3 part of antioxidant , 0.4 parts of anti-aging agent, 8 parts of foam regulator, 4 parts of coupling agent, 25 parts of oxidized polyethylene wax, 0.2 part of lubricant, 8 parts of chlorinated polyvinyl chloride, 3 parts of semi-reinforcing carbon black.

[0017] The antioxidant is specifically antioxidant 1010; the antioxidant is specifically antioxidant MB; the mixed fiber is formed by mixing glass fiber, carbon fiber and wood fiber in a weight ratio of 3:4:3, wherein the plant fiber It needs to be dried until the water con...

Embodiment 2

[0023] Embodiment 2: A kind of durable composite material tray, its raw material is as follows by weight: 55 parts of high-density polyethylene, 45 parts of copolymerized polypropylene, 35 parts of mixed fiber, 25 parts of plastic recycled materials, 8 parts of artificial zeolite , 1.5 parts of zinc stearate, 1.2 parts of calcium stearate, 8 parts of polyethylene glycol distearate, 12 parts of unsaturated polyester resin, 0.5 parts of vinyl triethoxysilane, 0.3 parts of antioxidant , 0.4 parts of anti-aging agent, 10 parts of foam regulator, 6 parts of coupling agent, 28 parts of oxidized polyethylene wax, 0.3 part of lubricant, 12 parts of chlorinated polyvinyl chloride, 4 parts of semi-reinforcing carbon black.

[0024] The antioxidant is specifically antioxidant 1010; the antioxidant is specifically antioxidant MB; the mixed fiber is formed by mixing glass fiber, carbon fiber and wood fiber in a weight ratio of 3:4:3, wherein the plant fiber It needs to be dried until the w...

Embodiment 3

[0030] Embodiment 3: A kind of durable composite material tray, its raw material is as follows by weight: 60 parts of high-density polyethylene, 50 parts of copolymerized polypropylene, 40 parts of mixed fiber, 30 parts of plastic recycled materials, 9 parts of artificial zeolite , 2 parts of zinc stearate, 2 parts of calcium stearate, 13 parts of polyethylene glycol distearate, 15 parts of unsaturated polyester resin, 0.6 part of vinyltriethoxysilane, 0.4 part of antioxidant , 0.6 parts of anti-aging agent, 10 parts of foam regulator, 8 parts of coupling agent, 30 parts of oxidized polyethylene wax, 0.3 parts of lubricant, 12 parts of chlorinated polyvinyl chloride, 4 parts of semi-reinforcing carbon black.

[0031] The antioxidant is specifically antioxidant 1010; the antioxidant is specifically antioxidant MB; the mixed fiber is formed by mixing glass fiber, carbon fiber and wood fiber in a weight ratio of 3:4:3, wherein the plant fiber It needs to be dried until the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com