Super-hydrophilic coating layer for cell culture and preparation method

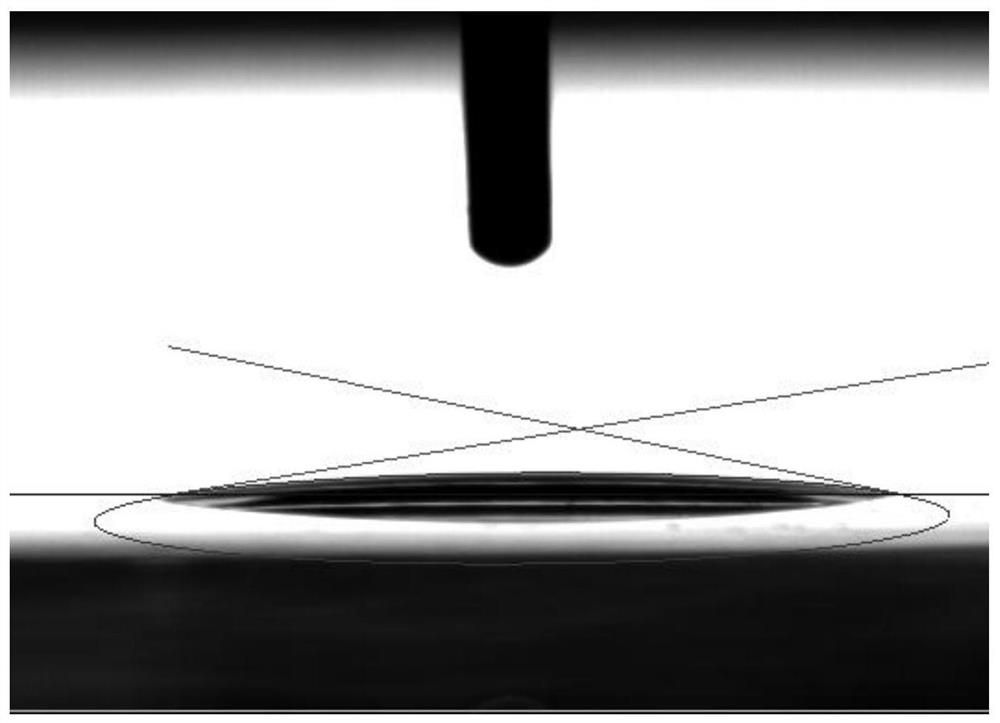

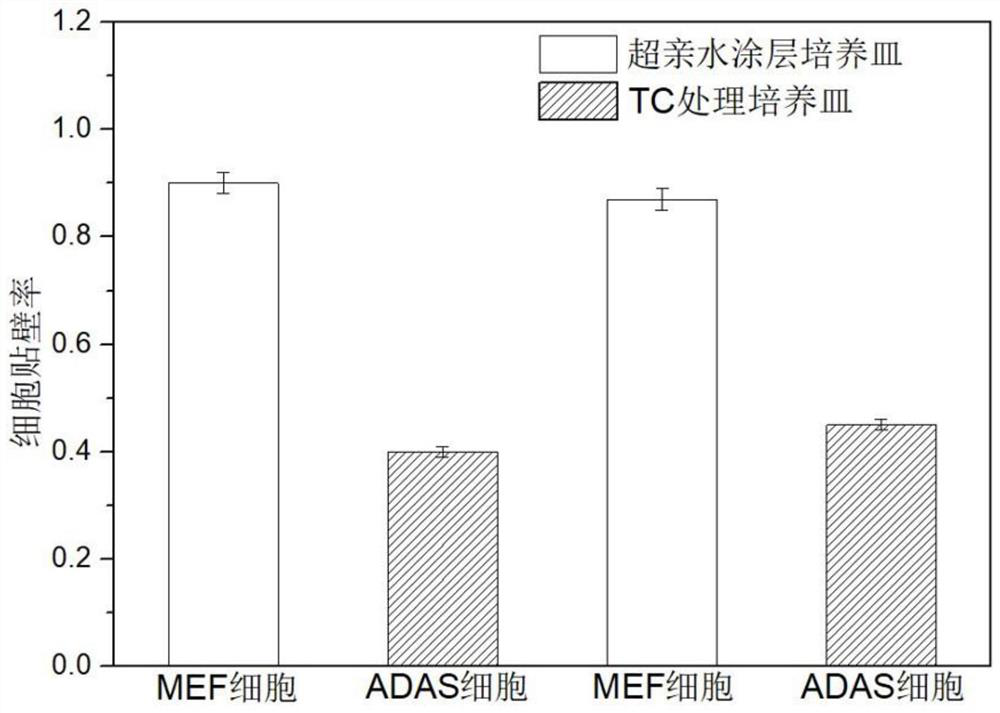

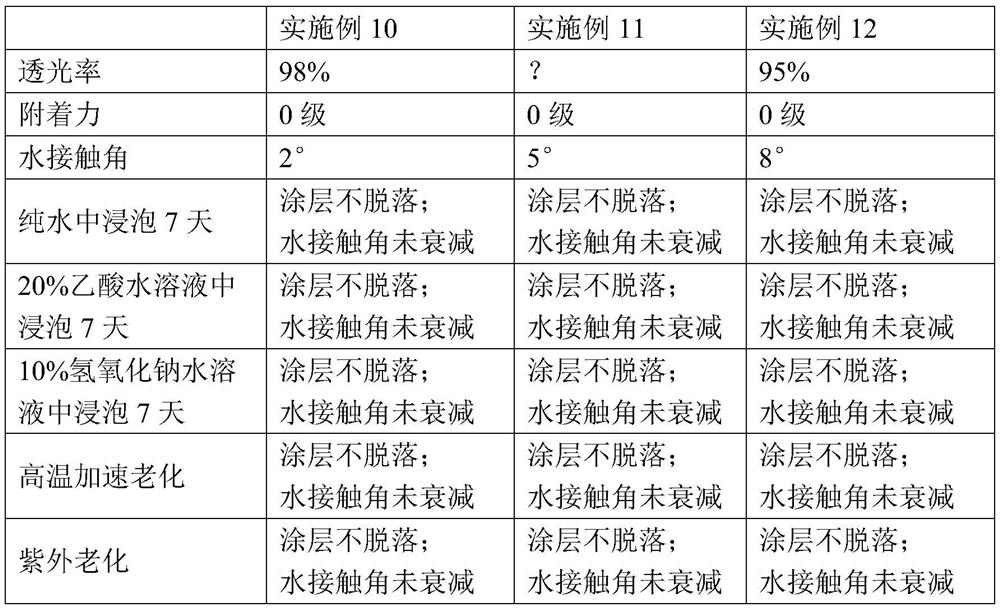

A cell culture, super-hydrophilic technology, applied in cell culture supports/coatings, biochemical equipment and methods, coatings, etc. problems such as poor layer stability and difficult cell culture, to achieve stable super-hydrophilic effect, low cost, and high cell adherence rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 configures chitosan solution

[0037] Dissolve 1 g of chitosan (viscosity 400 mPa.s) in 99 g of acetic acid aqueous solution, the mass fraction of chitosan is 1%, and the pH of the solution is 4.

Embodiment 2

[0038] Embodiment 2 configures chitosan solution

[0039] Dissolve 1 g of chitosan (viscosity 400 mPa.s) in 99 g of acrylic acid aqueous solution, the mass fraction of chitosan is 1%, and the pH of the solution is 5.

Embodiment 3

[0040] Embodiment 3 configures chitosan solution

[0041] Dissolve 1 g of chitosan (viscosity 400 mPa.s) in 99 g of hydrochloric acid solution, the mass fraction of chitosan is 1%, and the pH of the solution is 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com