Low-foam cleaning agent as well as preparation method and application thereof

A cleaning agent and low-foaming technology, applied in the field of cleaning, can solve the problems of high risk, difficult to scrub, low cleaning efficiency, etc., and achieve the effect of improving the ability of dissolving oil dirt, protecting the cleaning surface and improving cleaning power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides the preparation method of the low-foam cleaning agent described in the above scheme, comprising the following steps:

[0043] Mix surfactants, alkaline substances, oily solvents, alkaloids, bactericides, scale inhibitors and water, and after all the raw materials are dissolved, a low-foaming cleaning agent is obtained.

[0044] In the present invention, the mixing process preferably includes: heating the water to 55-65°C, adding the surfactant into the hot water, and stirring until completely dissolved to obtain the first mixed solution;

[0045] After cooling the first mixed liquid, add the oily solvent and stir to obtain the second mixed liquid;

[0046] adding an alkaline substance to the second mixed solution, stirring until dissolved, to obtain a third mixed solution;

[0047] Adding alkaloids to the third mixed solution, stirring until dissolved, to obtain a fourth mixed solution;

[0048] Adding a bactericide to the fourth mixed solution,...

Embodiment 1

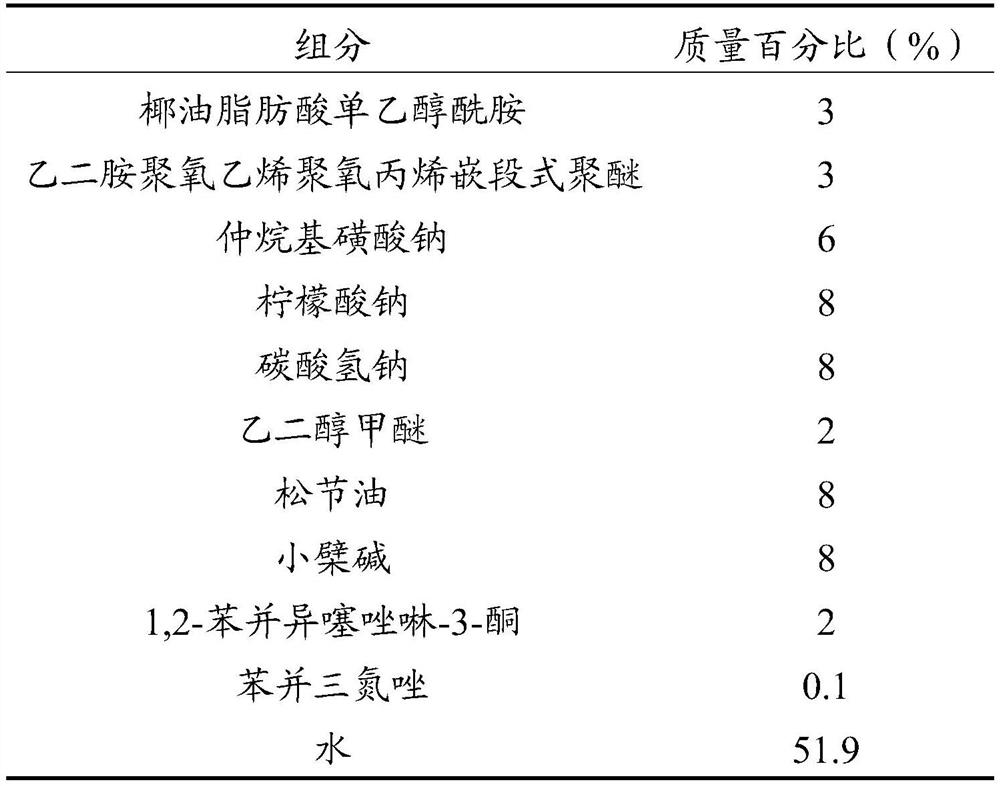

[0054] The composition of the low-foaming detergent is shown in Table 1.

[0055] The composition of table 1 embodiment 1 cleaning agent

[0056]

[0057] The preparation method is:

[0058] (1) Take coconut oil fatty acid monoethanolamide, ethylenediamine polyoxyethylene polyoxypropylene block polyether, secondary alkylsulfonate sodium, sodium citrate, sodium bicarbonate, ethylene glycol methyl ether, turpentine, Berberine, 1,2-benzisothiazolin-3-one, benzotriazole;

[0059] (2) Heat the water to 60°C, add coconut oil fatty acid monoethanolamide, ethylenediamine polyoxyethylene polyoxypropylene block polyether, and secondary alkyl sodium sulfonate and stir until completely dissolved;

[0060] (3) Add ethylene glycol methyl ether and turpentine after the solution is cooled, and stir evenly;

[0061] (4) Add sodium citrate and sodium bicarbonate, stir and dissolve evenly;

[0062] (5) add berberine, stirring and dissolving;

[0063] (6) Add 1,2-benzisothiazolin-3-one, s...

Embodiment 2

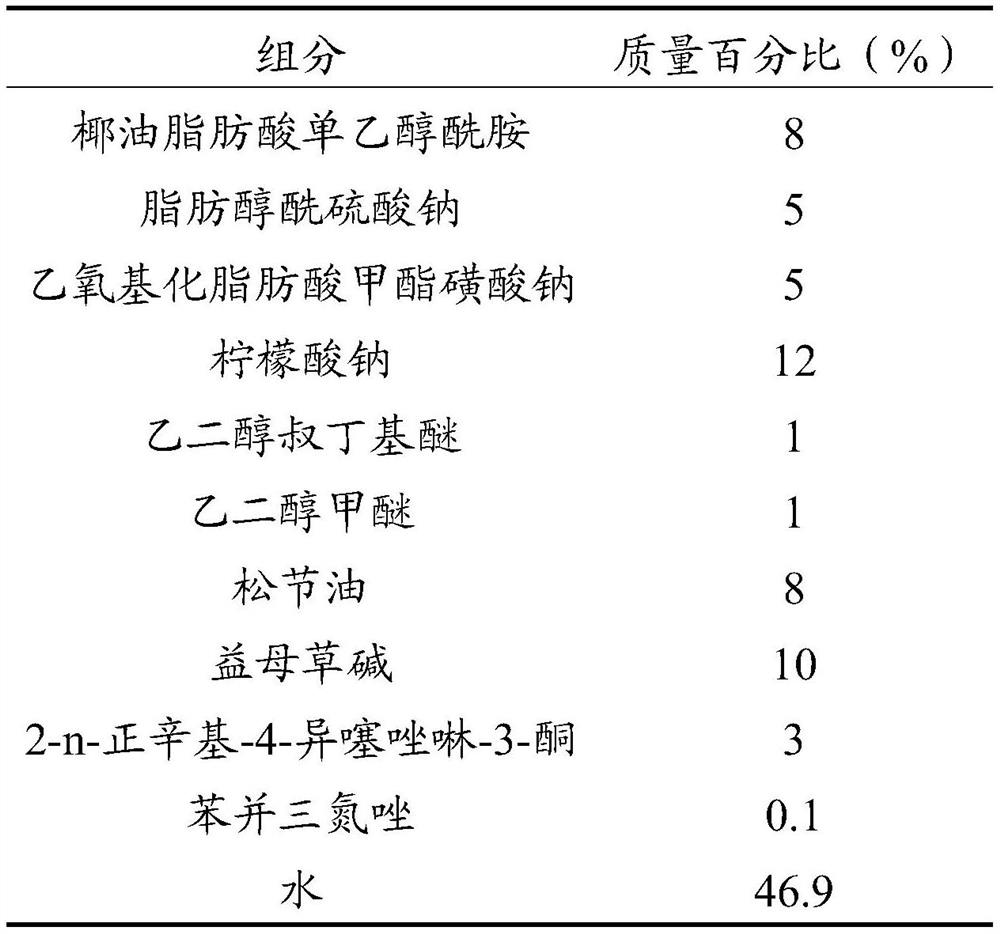

[0066] The composition of the low-foaming detergent is shown in Table 2.

[0067] The composition of table 2 embodiment 2 cleaning agents

[0068]

[0069] The specific preparation process is:

[0070] (1) Take coconut oil fatty acid monoethanolamide, fatty alcohol acyl sulfate sodium, ethoxylated fatty acid methyl ester sulfonate sodium, sodium citrate, ethylene glycol tert-butyl ether, ethylene glycol methyl ether, turpentine according to weight , Leonurine, 2-n-octyl-4-isothiazolin-3-one, benzotriazole;

[0071] (2) Heat water to 60°C, add coconut oil fatty acid monoethanolamide, sodium fatty alcohol acyl sulfate, sodium ethoxylated fatty acid methyl ester sulfonate and stir until completely dissolved;

[0072] (3) Add ethylene glycol tert-butyl ether, ethylene glycol methyl ether, turpentine after the solution is cooled, and stir evenly;

[0073] (4) Add sodium citrate, stir and dissolve evenly;

[0074] (5) add motherwort, stir and dissolve evenly;

[0075] (6) Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com